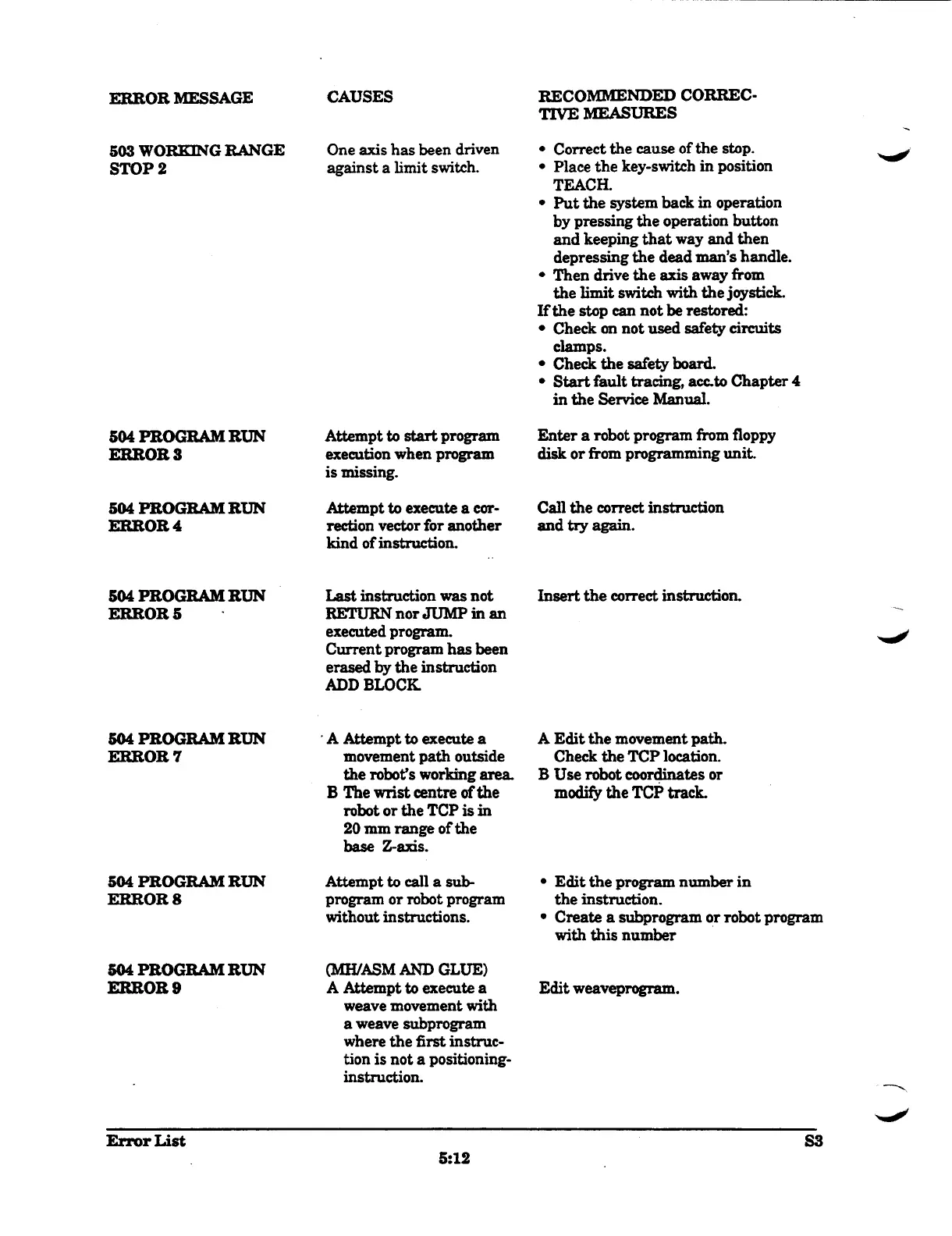

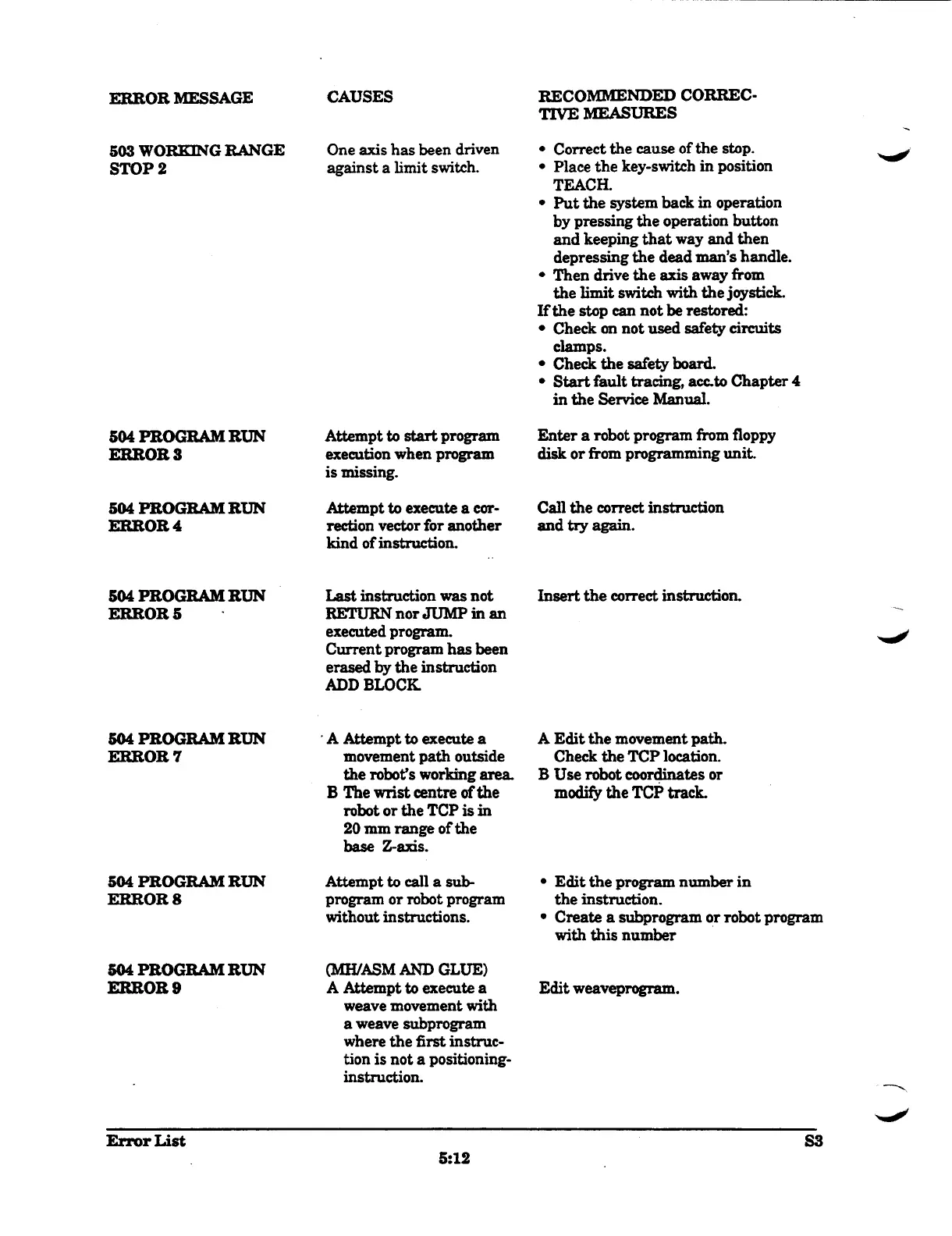

504 PROGRAM RUN

ERROR 3

504 PROGRAM RUN

ERROR 4

504 PROGRAM RUN

ERROR 5

504 PROGRAM RUN

ERROR 7

Error List

Attempt to start program

execution when program

is missing

.

Attempt to execute a cor-

rection vector for another

kind of instruction

.

Last instruction was not

RETURN nor JUMP

in an

executed program

.

Current program has been

erased by the instruction

ADD BLOCK

A Attempt to execute a

movement path outside

the robot's working area

.

B The wrist centre of the

robot or the TCP is in

5

:12

Enter a robot program from floppy

disk or from programming unit

.

Call the correct instruction

and try again

.

Insert the correct instruction

.

A Edit the movement path

.

Check the TCP location

.

B Use robot coordinates

or

modify the TCP track

.

S3

20 mm range of the

base Z-axis

.

504 PROGRAM RUN

Attempt to call a sub-

•

~

Edit the program number in

ERROR 8

program or robot program

the instruction

.

without instructions

.

•

~

Create a

subprogram

or

robot program

with this number

504 PROGRAM RUN

(MH/ASM AND GLUE)

ERROR 9

A Attempt to execute a

Edit weaveprogram

.

weave movement with

a weave subprogram

where the first instruc-

tion is not a positioning-

instruction

.

ERROR MESSAGE

503 WORE3NG RANGE

STOP 2

CAUSES

One axis has been driven

against a limit switch

.

RECOMMENDED CORREC-

TIVE MEASURES

•

~

Correct the cause of the stop

.

•

~

Place the key-switch in position

TEACH

.

•

~

Put the system back in operation

by pressing the operation button

and keeping that way and then

depressing the dead man's handle

.

•

~

Then drive the

axis

away

from

the limit switch with the joystick

.

If the stop can not be restored

:

•

~

Check

on

not used safety circuits

clamps

.

•

~

Check the safety board

.

•

~

Start fault tracing,

a

cc

.t

o

Chapter 4

in the Service Manual

.

Loading...

Loading...