EVO 150 Controller

12

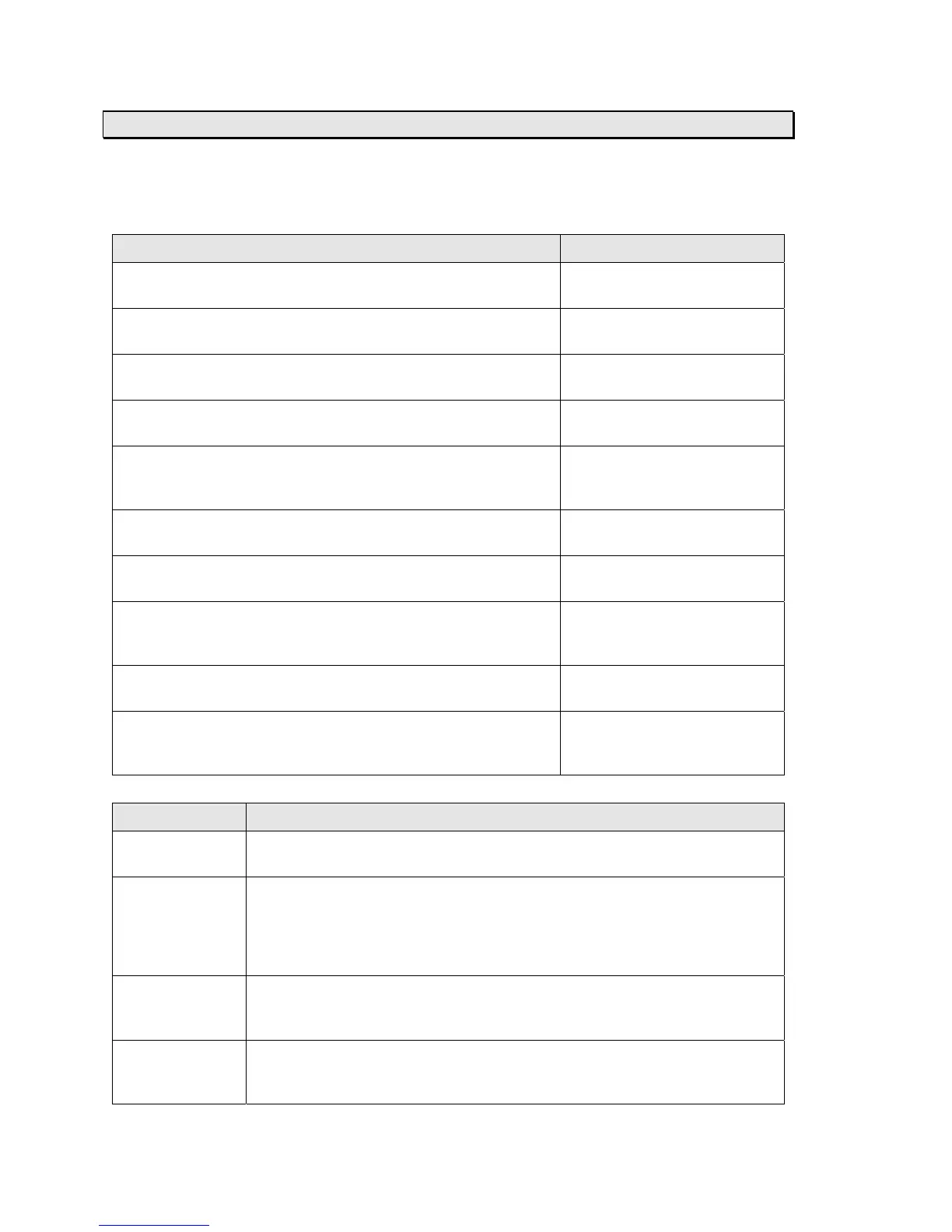

Troubleshooting

The following checklist has been provided to assist in the analysis and repair of potential trouble

situations with the EVO 150 system. If a situation occurs that is not described in this list, contact

AccuWeb for assistance.

Problem Solution

The system will not work in Automatic, Manual, or Servo-

Center mode.

Check items 1, 2, 3, and 4 in

the table below.

When the system is in Automatic mode, the web guide steers

the web in the wrong direction.

Check item 6 in the table

below.

The system oscillates in Automatic mode even though web is

not being pulled through the machine.

Check items 7 and 8 in the

table below.

The system is unstable in Automatic mode while pulling web. Check items 9, 10, 11, and 12

in the table below.

The actuator extends or retracts beyond the actuator’s end-of-

travel limits then jams.

Check items 13, 14, 15, 16,

17, 18, and 19 in the table

below.

The web guide or actuator hits a mechanical stop before

reaching the actuator's end-of-travel limit.

Check item 15 in the table

below.

The system will not work in Automatic mode but works

correctly in Manual and Servo-Center mode.

Check items 20, 21, and 22 in

the table below.

While in Automatic mode the web guide or actuator moves too

fast or slow in response to large changes in the position of the

edge of the web (such as a splice).

Check item 23 in the table

below.

While in Manual mode the web guide or actuator moves too

fast or too slow.

Check item 24 in the table

below.

It is necessary to perform a “Power-up Reset”: If a power-up reset is

necessary, then check item 5

in the table below.

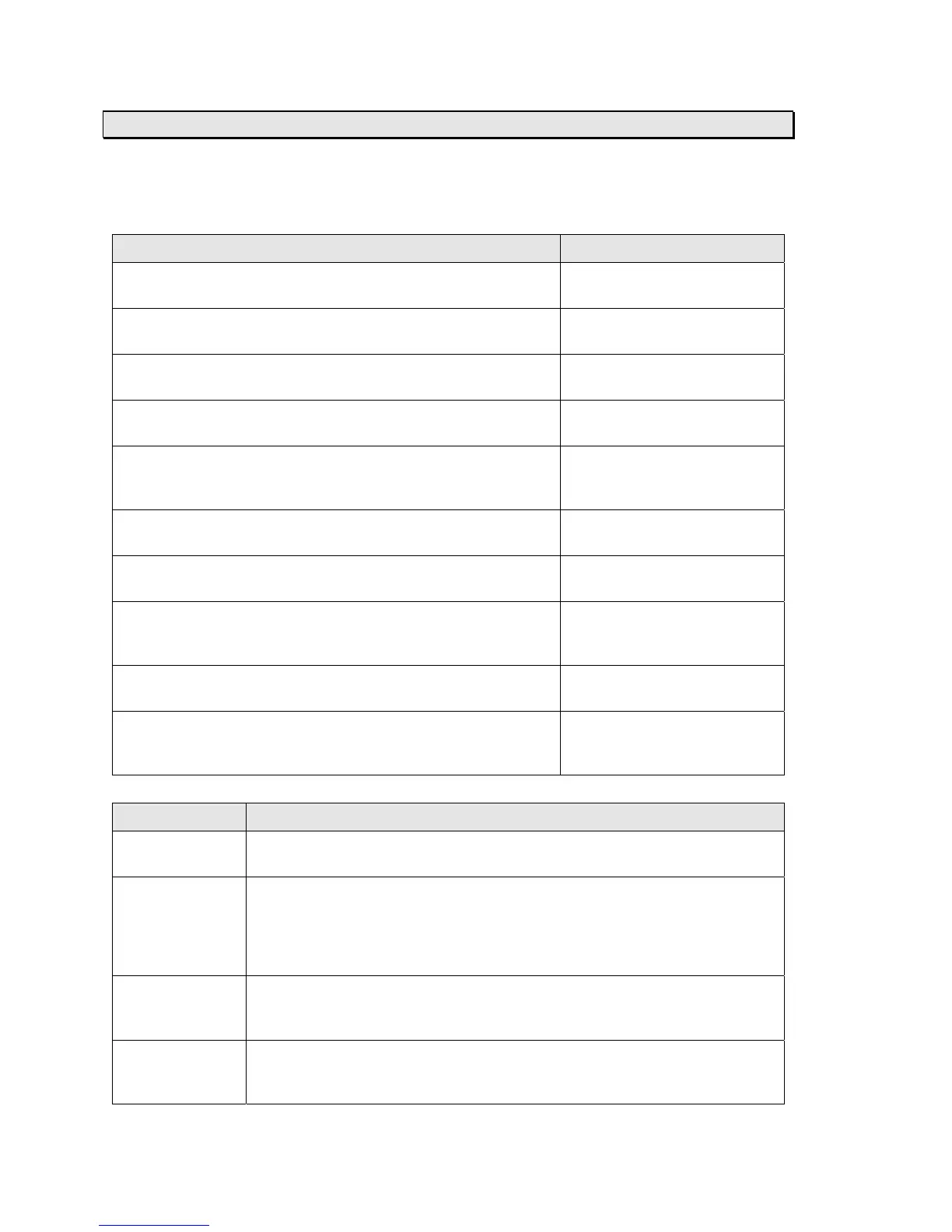

Item Description / Repair Procedure

1 DC power. If the LED near S1 is not lit or the switch pad LED’s are not lit,

check the DC power and repair if not connected.

2 No output from the PWM motor drive. Connect a digital voltmeter to the

actuator motor leads at J6 terminals 1 and 2. Press the MANUAL button

and then press and hold the IN or OUT button. If there is no voltage but the

LED near S1 is lit, the PWM motor output has failed and the system must

be returned for repair.

3 Actuator failure. If there is motor voltage present in the previous step but

the actuator does not move, the actuator motor or cable has failed.

Troubleshoot and repair as required, or return the equipment for repair.

4 INHIBIT input polarity is set wrong. Set parameter 19 to the correct

value. Refer to page 21 for more information about setting controller

parameters.

Loading...

Loading...