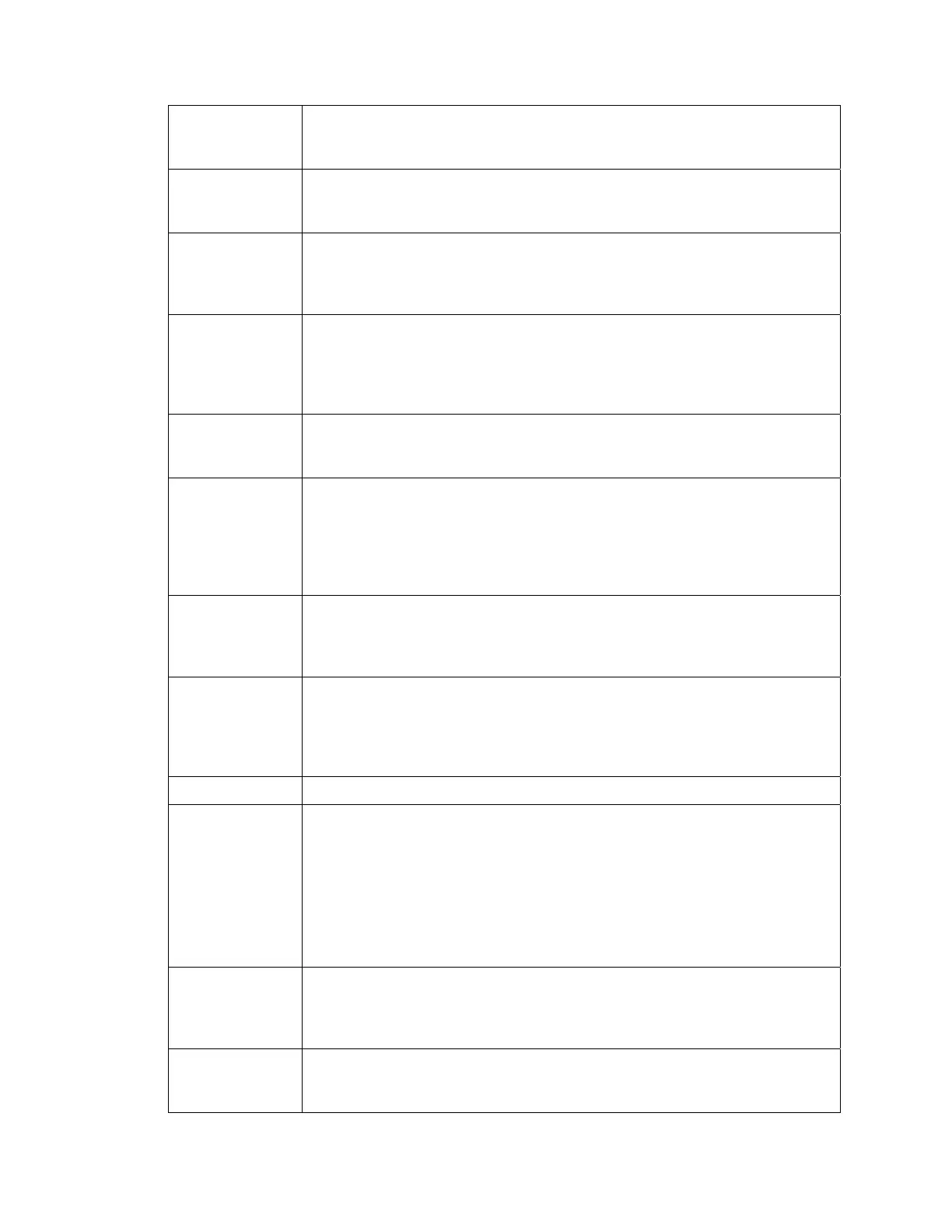

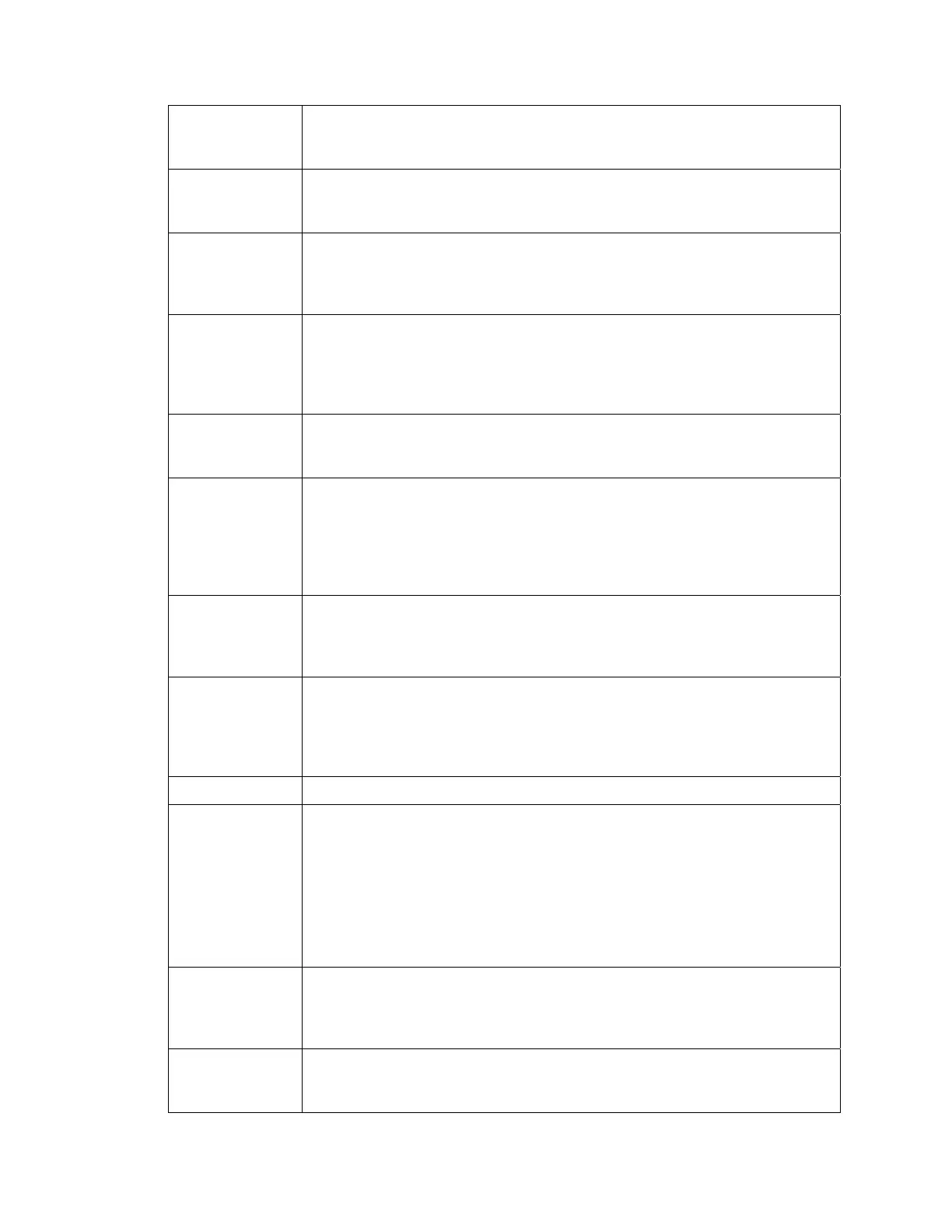

Excessive web curl. If web flutter or curl exists, change parameters 6 and

18 to higher values. Refer to page

12

17 for more information about setting

controlle

r parameters.

All actuators. End-of-travel mode is incorrect. Set parameter 2 to the

correct value. Refer to page

13

17 for more information about setting controller

para

meters.

14

All actuators. Actuator cable wires are broken, shorted or connected

to

wrong terminals of J5. Refer to the connection diagrams on page 137.

C

heck wiring at J5 and check the actuator cable for broken or shorted

wires.

15

Actuators with potentiometer feedback (MT, SF, HL, HF, HT, and UHT).

End-of-trav

el limits not set correctly. Parameters 9 and 10 must be

adjusted to stop the actuator before the web guide or actuator hits any

obstruction. Refer to page

17 for more information about setting controller

para

meters.

16

Actuators with potentiometer feedback (MT, SF, HL, HF, HT, and UHT).

Potentiometer failure.

Refer to the potentiometer replacement procedure

on page

86.

17

Actuators with limit switches (MM, MME, MN, and MNE). Limit s

witch

failure. Check the limit switch voltage at J5 terminals 5 and 6 (terminal 10

is GND). This voltage should normally be 0.0 VDC (switch is closed), then

jump to +5.0 VDC when the limit is reached (switch opens). If the correct

voltages are not present, replace the limit switch in the actuator or return

the actuator for repair.

Actuators with limit switches (MX). Limit switch failure. The end-of-

travel limit switches in the MX-series actuators directly control the motor

circuit and cannot be monitored externally. If a limit switch has failed,

replace the switch or return the actuator for repair.

18

Reversed motor wires. Restore the motor wire connections at J5

terminals 1 and 2 to the proper connection. Refer to the connection

diagrams on page

19

137. Change the value of parameters 3, 4, or 50 as

requi

red. Refer to page 17 for more information about setting controller

para

meters.

Edge detector not calibrated. Refer to page 20 58 for calibration instructions.

Edge detector: transducers covered with dust or other material. Clean

the edge detector transducer face with a cloth dampened with water or a

mild detergent solution. If the contamination cannot be removed with this

method, return the edge detector for repair.

21

Digital line guide: optic

s covered with dust or other material. Clean the

underside of the sensor with a soft cloth dampened with water or a cleaning

solution suitable for photographic lenses. If the contamination cannot be

removed with this method, return the sensor for repair.

Edge detector failure. Observe the value of parameter 14 or 15 as

required. If this value is below 100, the edge detector is failing and must be

returned for repair. Refer to page

22

17 for more information about displaying

controlle

r parameter settings.

Auto-mode speed limit setting is incorrect. Change the value of

parameter 7. Refer to page

23

17 for more information about setting controller

para

meters.

MICRO 4000

NET Web Guide Control System

13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...