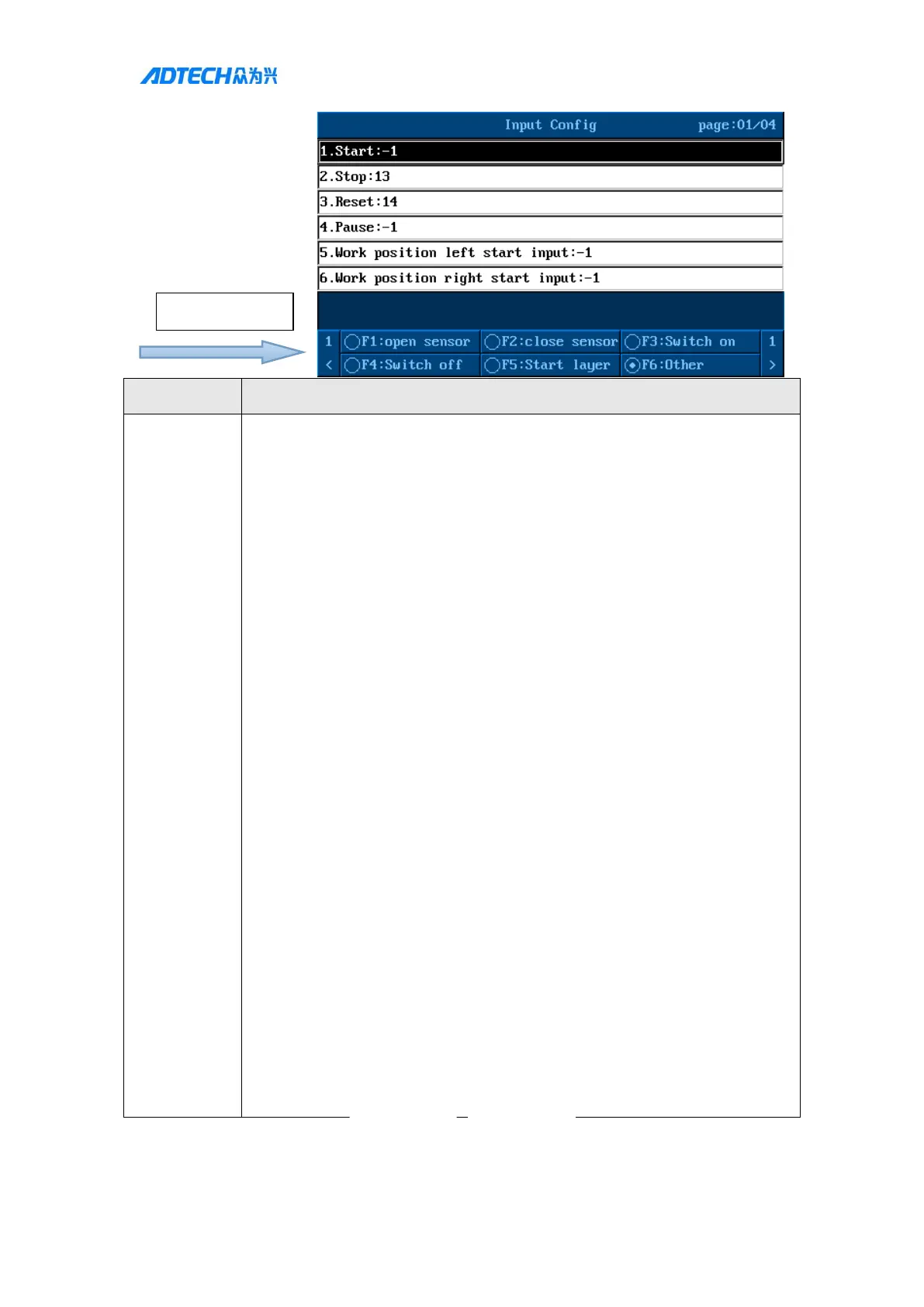

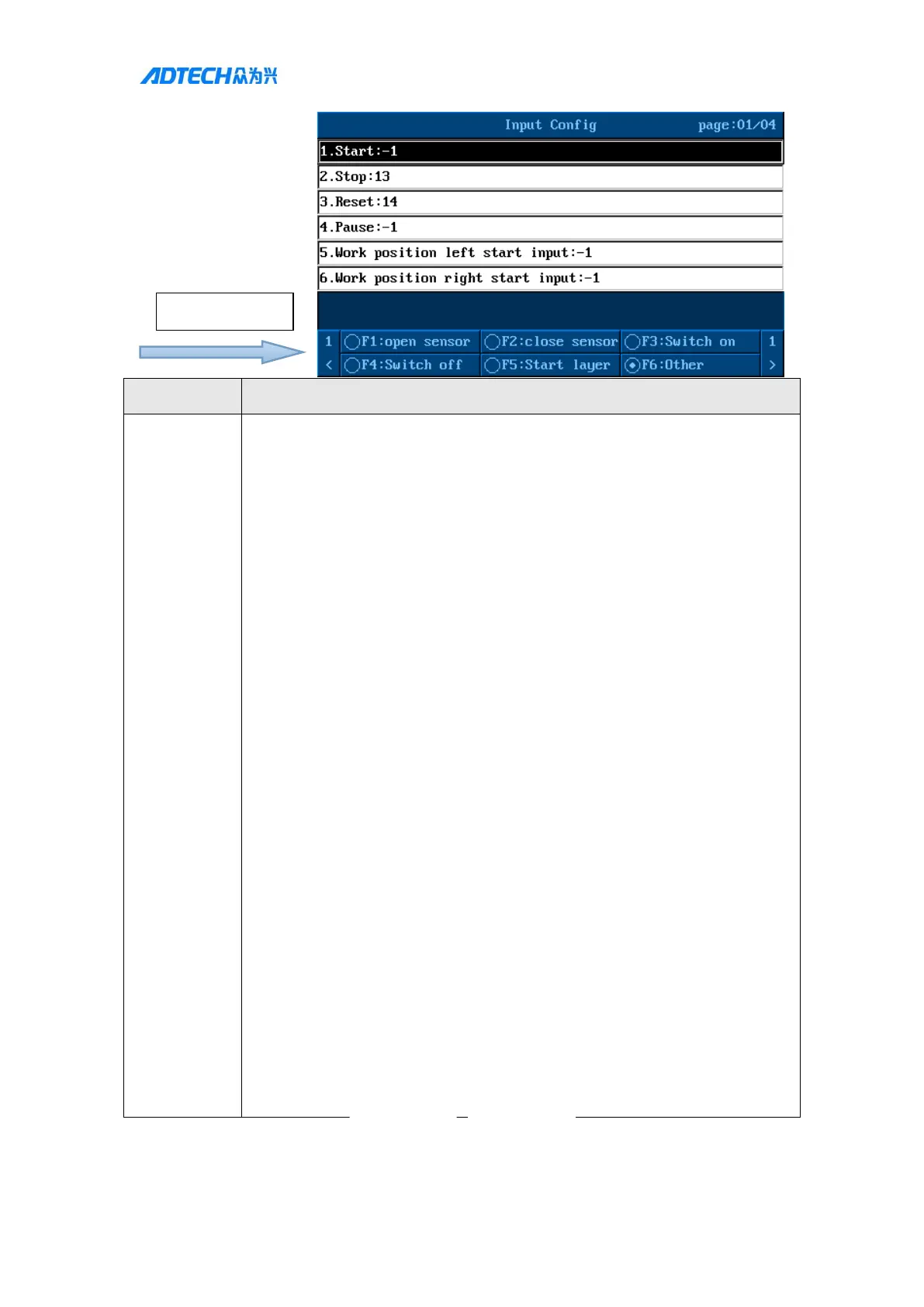

※Note: You can set the port number corresponding to the common input

function. Setting to -1 will disable this function.

1) Start: External start button port (valid for single position system)

2) Stop: External emergency stop button port

3) Reset: External reset button port

4) Pause: External pause button port

5) Left position start: External left position start button configured when it is a

dual position system

6) Right position start: External right position start button configured when it is

a dual position system

7) Safe gate: Safety light gridRight

8) Left table safe gate: Left safety light grid

9) Right table safe gete: Right safety light grid

10) Safe gate electrical lever: Safety grating active level

11) Step key:Single step button input

12) External alarm input: When the signal level is low, the machining stops and

generatesalarm output

13) External needle aligning button: When the button is pressed for the first

time, XY moves to the aligning position, and when it is pressed again within 3

seconds, the Z axis moves to the aligning position

14) Back to standby position button: When the button is pressed, it moves to the

set standby position

15) Cycle machining switch button: When the button is pressed, it enters the

cycle machining state, and when it is lifted, it enters a single machining state

16) External glue gun control button: Manual glue open/close control

17) BCD DIP switch input start point: You can use two-digit BCD8421 DIP

switches to select files. The two-digitDIP switch occupies8 continuously input

points. For example, if the input start point is set to 17, the wiring method is

as follows:

Loading...

Loading...