3-6 Option 100 Fault Location and SRL

Making Fault Location Measurements

How to Make and Interpret Fault Location Measurements

3. Calibrate the Analyzer

When practical, a calibration should be done at the measurement

reference plane using open, short, and load calibration standards to

correct the instrument and optimize accuracy. If calibration standards

are not available, the default instrument calibration can be used.

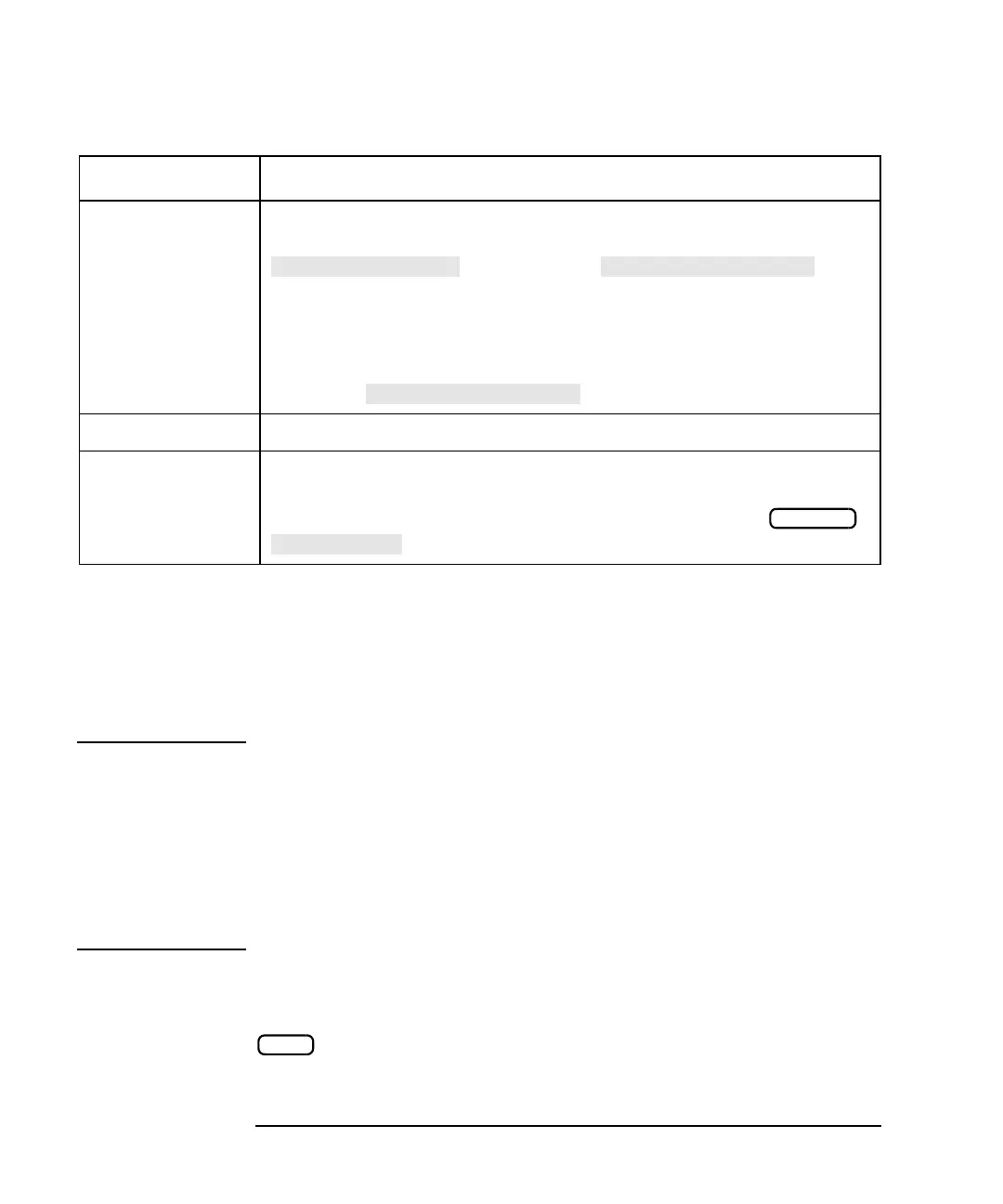

NOTE Most fault location measurements are made by connecting the cable

under test directly to the analyzer's RF OUT (or PORT 1) test port. In

this case the measurement reference plane would be the analyzer's port

and you would connect calibration standards to the RF OUT (or PORT 1)

test port as shown in Figure 3-1. Fault location measurements may also

be made using a test lead cable. If this is the case, the measurement

reference plane would be the end of the test lead cable as shown in

Figure 4-1 on page 4-5, and calibration standards would be connected to

the end of the test lead cable.

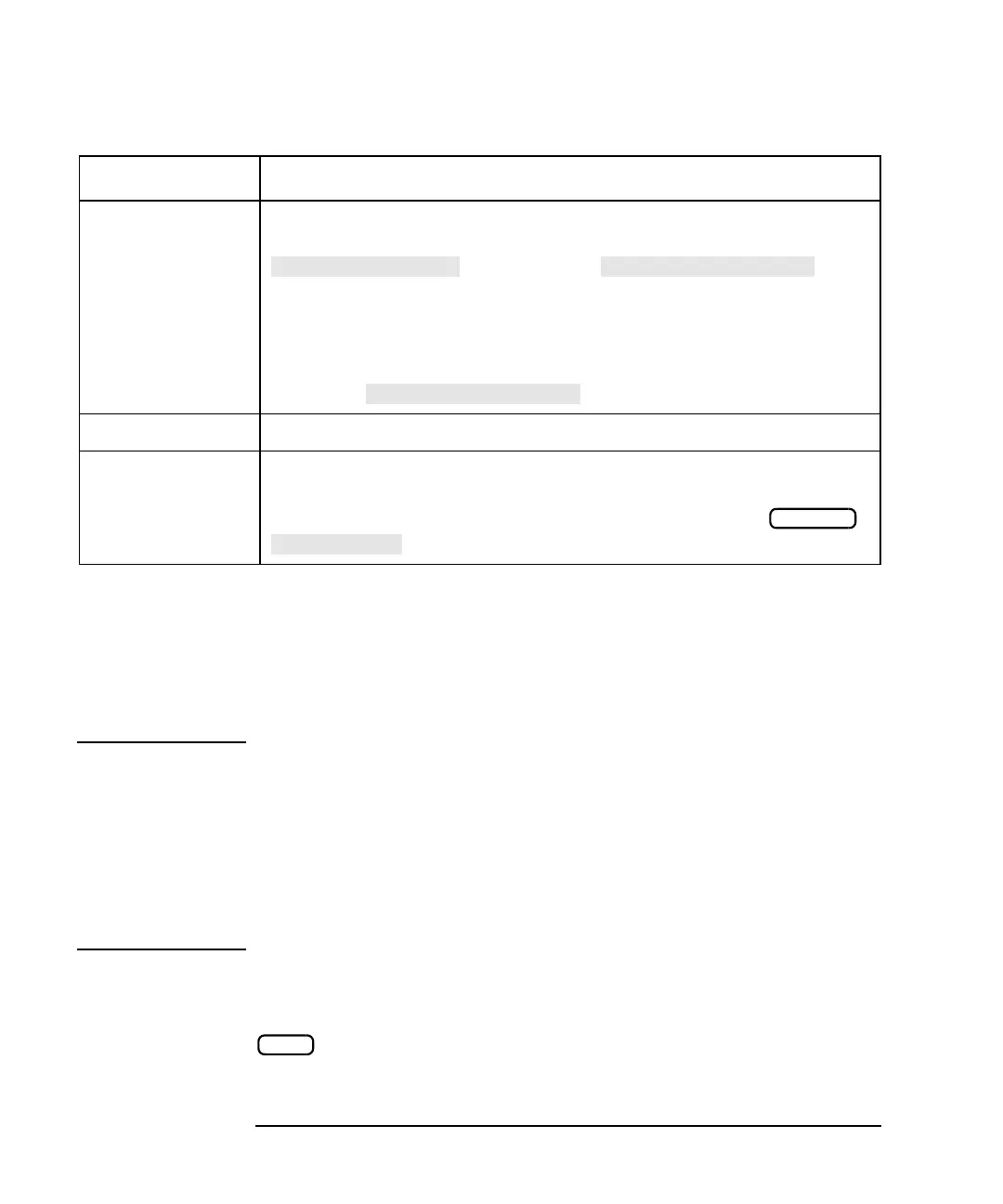

Entering Calibration Parameters

If fault location is already selected as the type of measurement, press

and then enter the velocity factor and cable loss parameters. The

value for cable loss should correspond to the center frenquency of the

range used for the fault measurement.

Band Pass Mode This mode is called bandpass because it works with band-limited

devices. Stimulus frequencies are limited to the range specified by the

setting and the (in

the fault loc frequency menu) setting. For example, bandpass mode

should be selected for measurements on systems which can operate

only over narrow specified frequency ranges.

In this mode, the frequency span for the fault measurement cannot

exceed the setting.

Center Frequency This parameter is only used with band pass mode.

Sweep Time When making fault location measurements, the sweep time is set

automatically based on the stop distance setting you have chosen.

Sweep time may be entered manually, however, using the

key.

Parameter Comments

SWEEP

CAL

Loading...

Loading...