7 Gas Selection and Plumbing

Gas Plumbing

Site Preparation Guide 49

Gas Plumbing

All compressed gas cylinders should be securely fastened to an immovable structure or

permanent wall. Compressed gases should be stored and handled in accordance with the

relevant safety codes.

Gas cylinders should not be located in the path of heated oven exhaust.

To avoid possible eye injury, wear eye protection when using compressed gas.

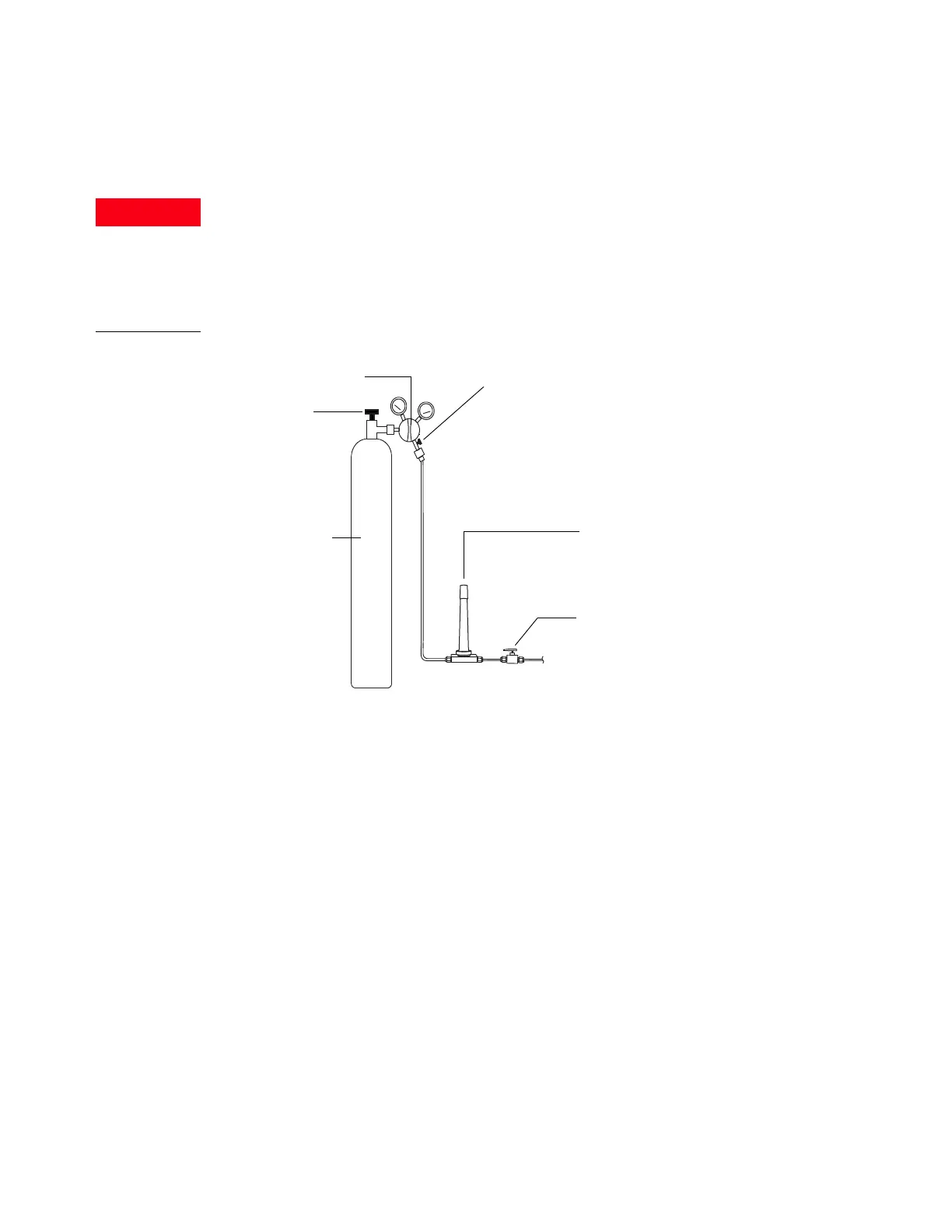

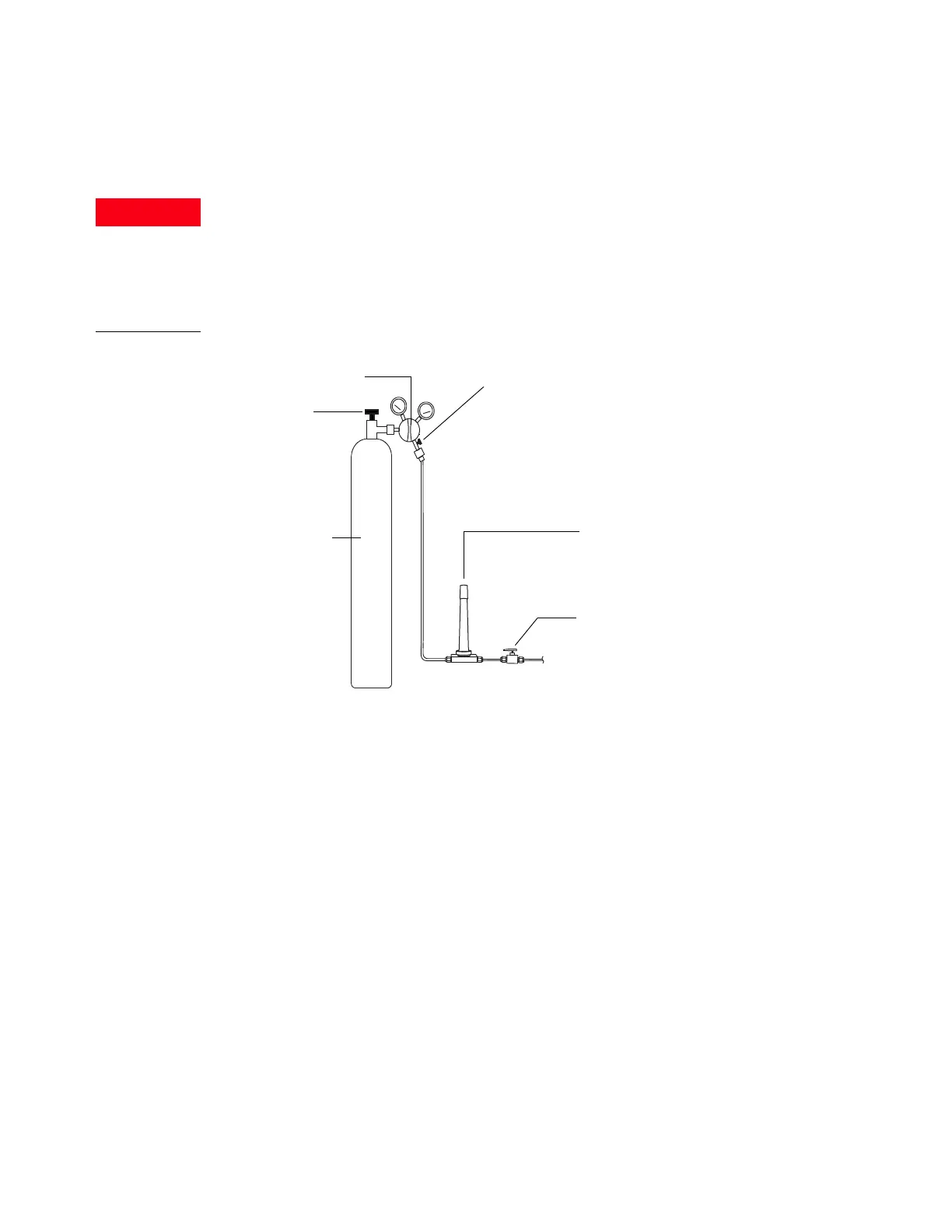

Figure 7. Recommended filters and plumbing configuration from a carrier gas cylinder

• If you have not requested option 305 (pre-plumbed tubing), you must supply pre-cleaned,

1/8-inch copper tubing and a variety of 1/8-inch Swagelok fittings to connect the GC to

inlet and detector gas supplies. See the Installation Kits for recommended parts.

• Agilent strongly recommends two-stage regulators to eliminate pressure surges.

High-quality, stainless-steel diaphragm-type regulators are especially recommended.

• On/off valves mounted on the outlet fitting of the two-stage regulator are not essential but

are very useful. Be sure the valves have stainless-steel, packless diaphragms.

• Agilent strongly recommends installation of shut-off valves at each GC inlet supply fitting

to allow the GC to be isolated for maintenance and troubleshooting. Order part number

0100-2144. (Note that some optional installation kits include one shut-off valve. See

“Installation Kits” on page 14 for more information.)

• If you purchased automated valving, the valve actuation requires a separate pressurized,

dry air supply at 380 kPa (55 psig). This air supply must end in a male fitting compatible

with a 1/4-inch id plastic tube at the GC.

Two-stage regulator

Main supply

on/off valve

Main gas

supply

On/off valve

Gas Clean filter

system. See “Filters

and traps”

on page 52

for more information.

Shutoff valve

Gas Clean filter configuration will vary depending on the

application.

Loading...

Loading...