7 Gas Selection and Plumbing

Gas Supplies

Site Preparation Guide 43

Gas Supplies

General requirements

Supply instrument gases using tanks, an internal distribution system, or gas generators. If

used, tanks require two-stage pressure regulators with packless, stainless steel diaphragms.

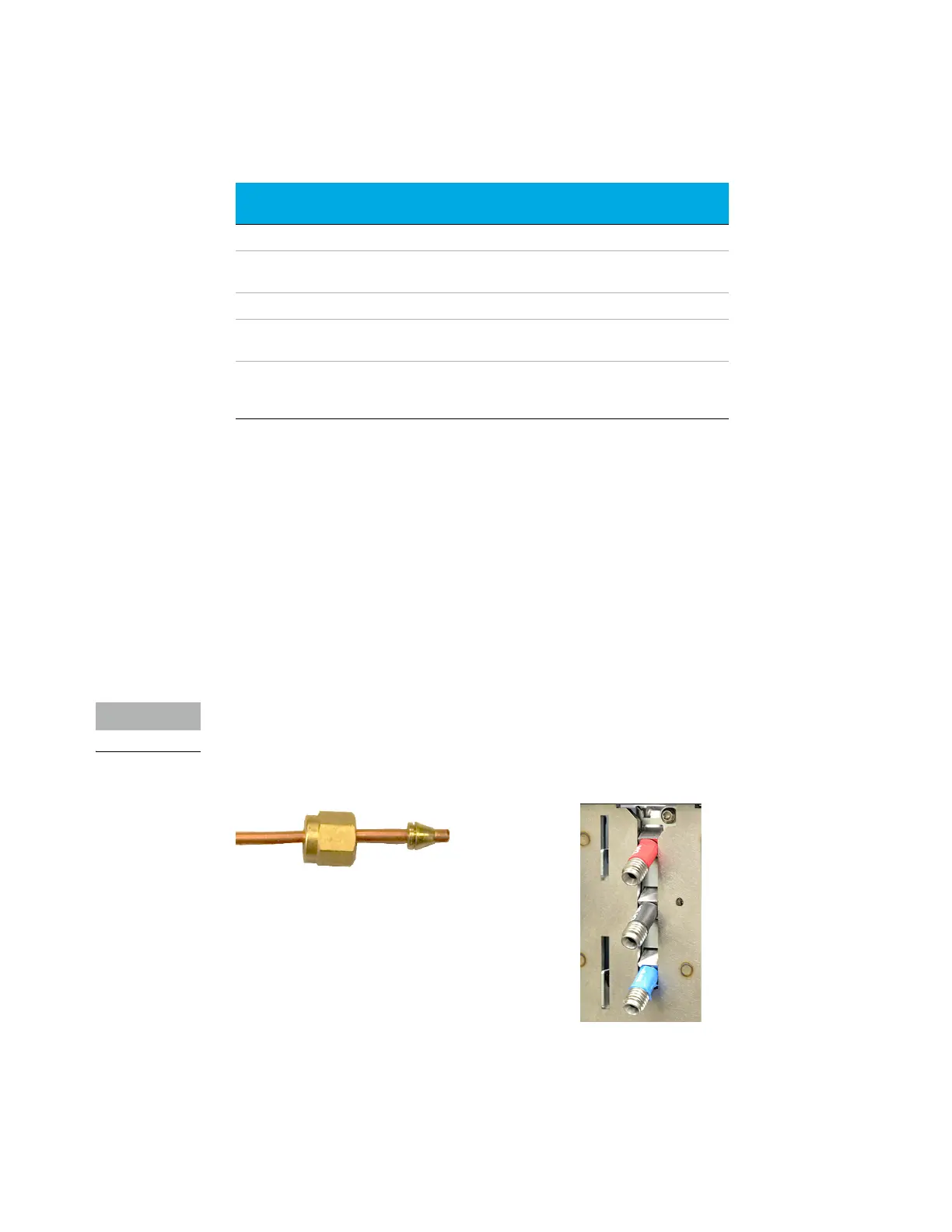

The instrument requires 1/8-inch Swagelok connections to its gas supply fittings.

See Figure 6.

Plumb the gas supply tubing/regulators so that one 1/8-inch Swagelok female connector is

available for each gas needed at the instrument.

Figure 6. Example Swagelok connector and hardware

Table 15 Carrier, collision and reagent gas purity

Carrier, collision and reagent gas

requirements

Purity

Notes

Helium (carrier) 99.9995% Hydrocarbon free

Hydrogen (carrier) (carrier and

self-cleaning ion source)

99.9995% SFC grade

Nitrogen (carrier) 99.9995%

Nitrogen (drying gas, nebulizer

pressure)

*

* Purity specification is the minimum acceptable purity. Major contaminants can be water,

oxygen, or air. Drying gas and nebulizer pressure gas can be supplied by a nitrogen gas

generator, house nitrogen system, or liquid nitrogen dewar.

99.999% Research grade

Methanol

†

† Required reagent for performance verification in internal CI mode only. Evaporation residue

<.0001%.

99.9% Reagent grade. Purge and

trap grade

recommended.

Swagelok nut and ferrules

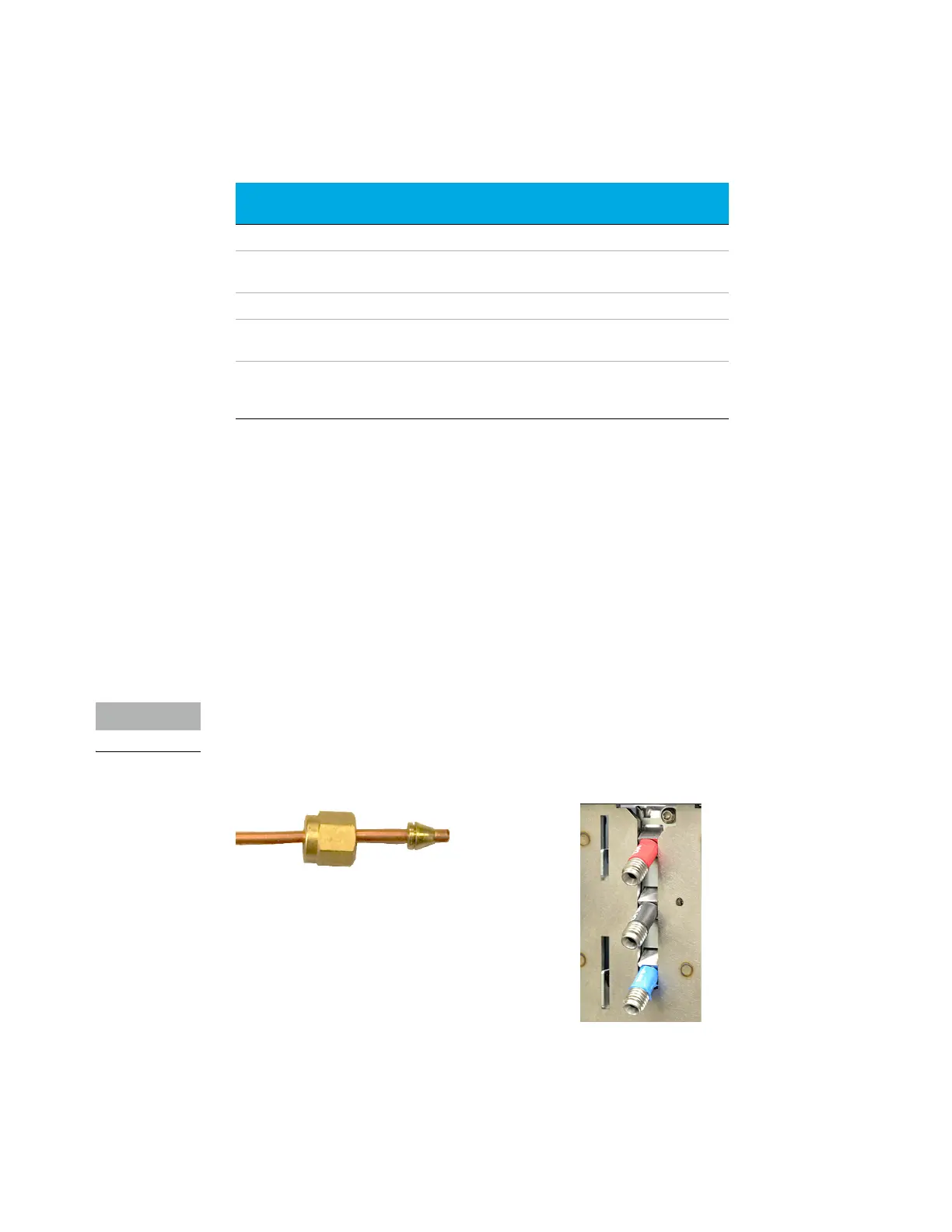

Female Swagelok fittings on GC

Loading...

Loading...