7 Gas Selection and Plumbing

Gas Supplies

44 Site Preparation Guide

Table 16 lists available Agilent two-stage tank regulators. All Agilent regulators are supplied

with the 1/8-inch Swagelok female connector.

Table 17 and Table 18 list minimum and maximum delivery pressures for inlets and detectors,

measured at the bulkhead fittings on the back of the instrument.

The minimum supply pressure for Auxiliary EPC and PCM modules is 138 kPa (20 psi) greater

than the pressure used in your method. For example, if you need a pressure of 138 kPa (20 psi)

for the method, the supply pressure must be at least 276 kPa (40 psi). Table 19 lists the

maximum carrier pressure for Auxiliary EPC and PCM modules.

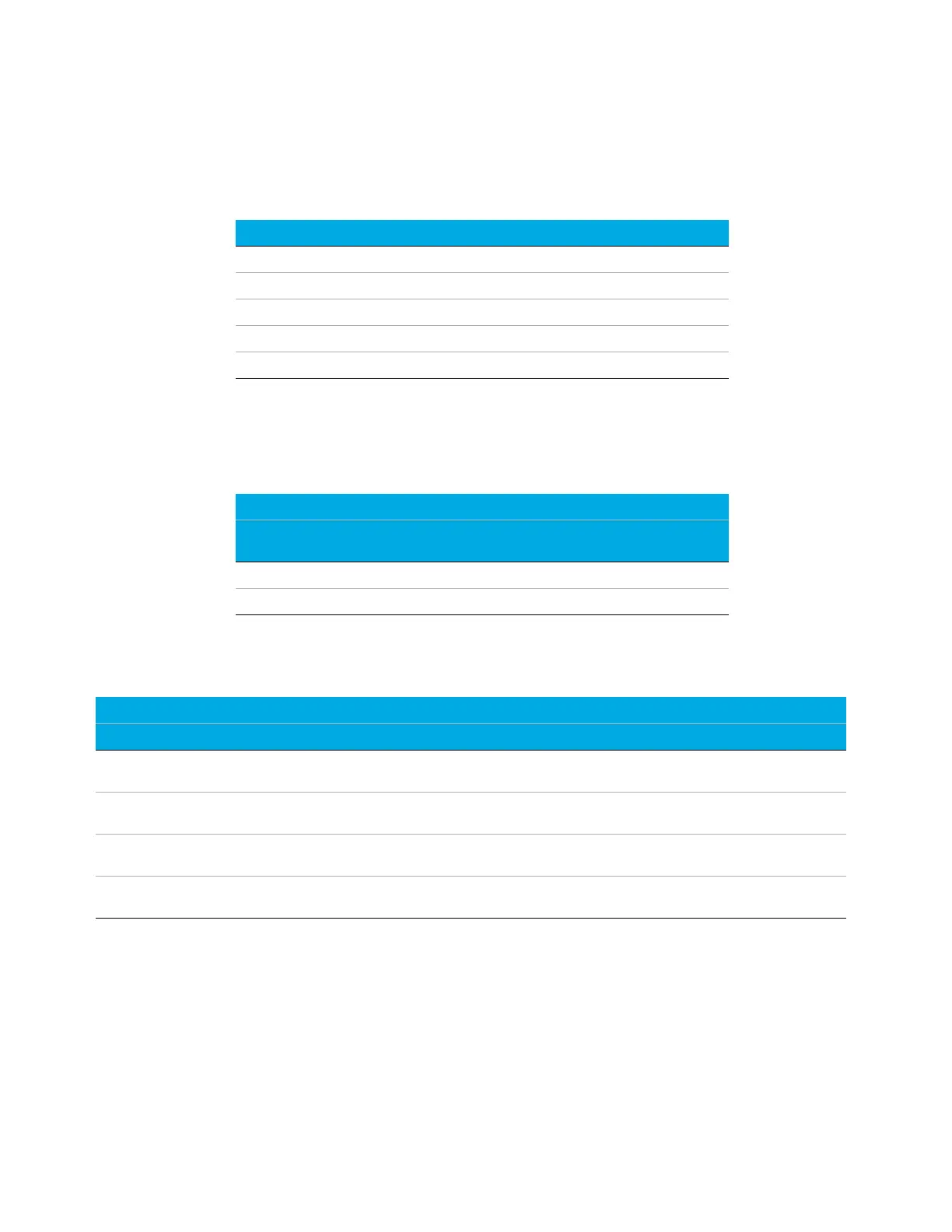

Table 16 Tank regulators

Gas type CGA number Max pressure Part number

Air 346 125 psig (8.6 Bar) 5183-4641

Industrial Air 590 125 psig (8.6 Bar) 5183-4645

Hydrogen, Argon/Methane 350 125 psig (8.6 Bar) 5183-4642

Oxygen 540 125 psig (8.6 Bar) 5183-4643

Helium, Argon, Nitrogen 580 125 psig (8.6 Bar) 5183-4644

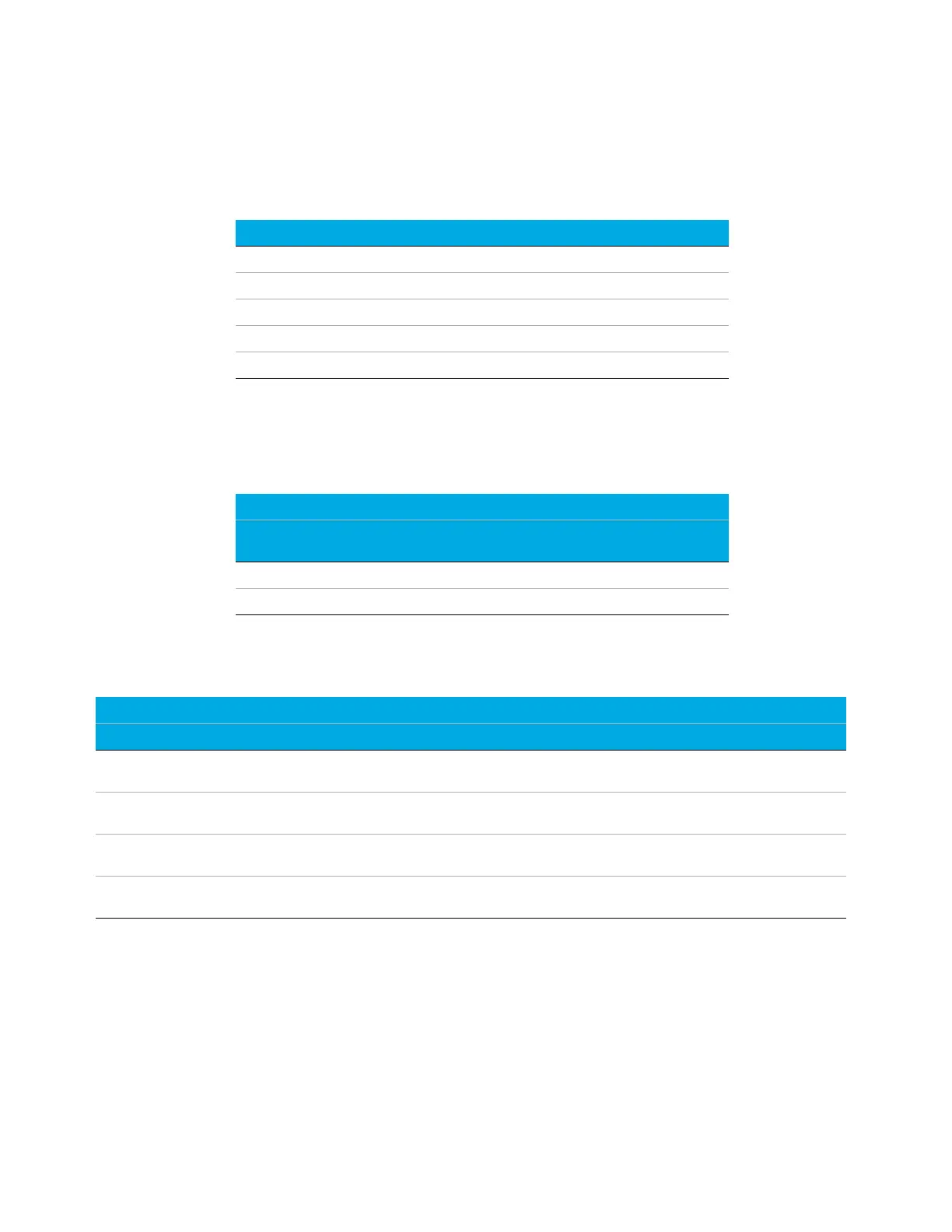

Table 17 Delivery pressures for inlets required at the GC, in kPa (psig)

Inlet type

Split/Splitless (SSL)

Purged packed

(PPI)

Packed

column(PCI)

Carrier (max) 827 (120) 827 (120)

Carrier (min) (20 psi) above pressure used in method

Table 18 Delivery pressures for detectors required at the GC/MS

*

Detector type

FID NPD TCD ECD FPD

Hydrogen 240–690 kPa

(35–100 psig)

240–690 kPa

(35–100 psig)

310–690 kPa

(45–100 psig)

Air 380–690 kPa

(55–100 psig)

380–690 kPa

(55–100 psig)

690–827 kPa

(100–120 sig)

Makeup 380–690 kPa

(55–100 psig)

380–690 kPa

(55–100 psig)

380–690 kPa

(55–100 psig)

380–690 kPa

(55–100 psig)

380–690 kPa

(55–100 psig)

Reference 380–690 kPa

(55–100 psig)

* Conversions: 1 psi = 6.8947 kPa = 0.068947 Bar = 0.068 ATM

Loading...

Loading...