Remote-controlled All-electric Tool Carrier agria 9700e

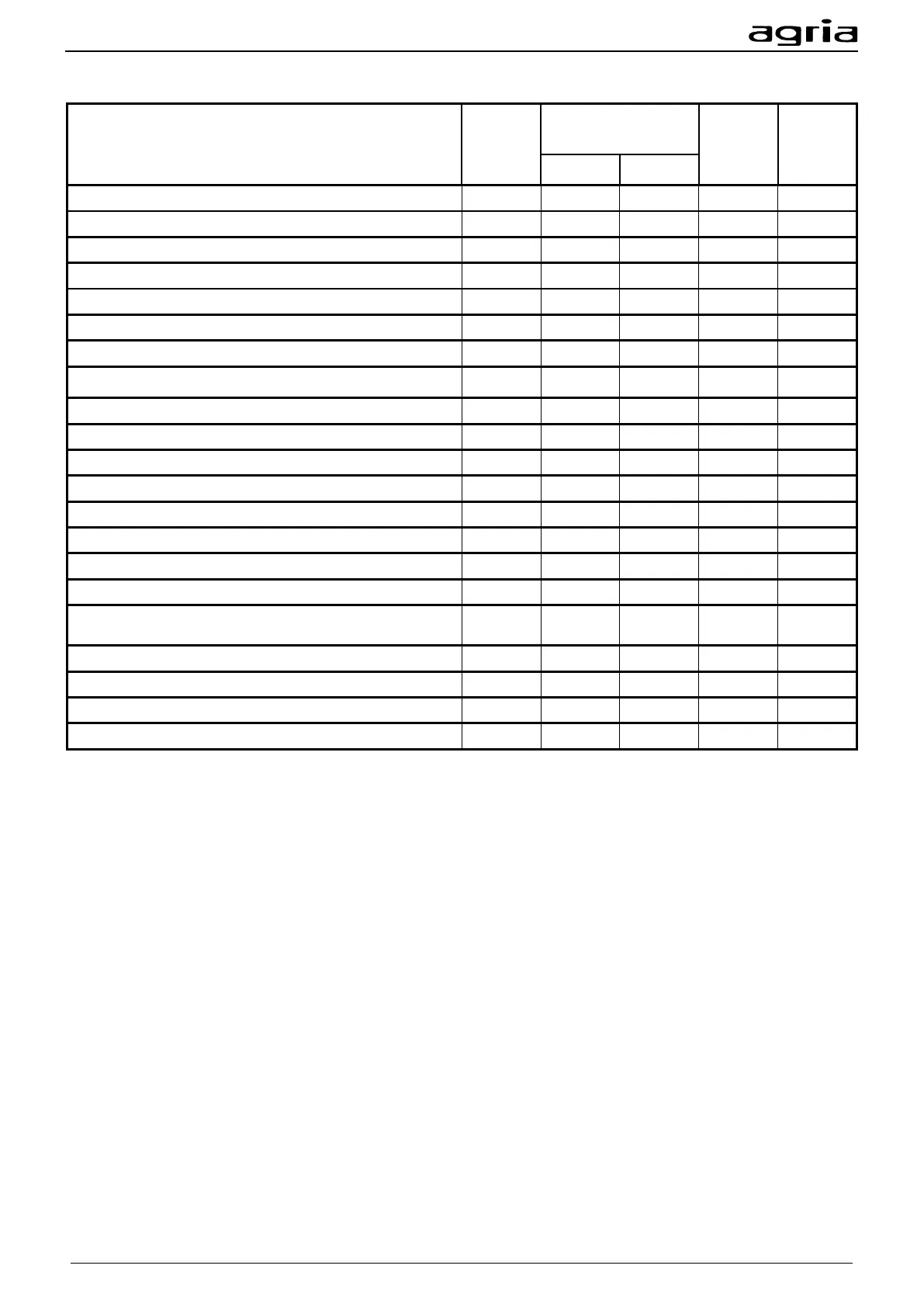

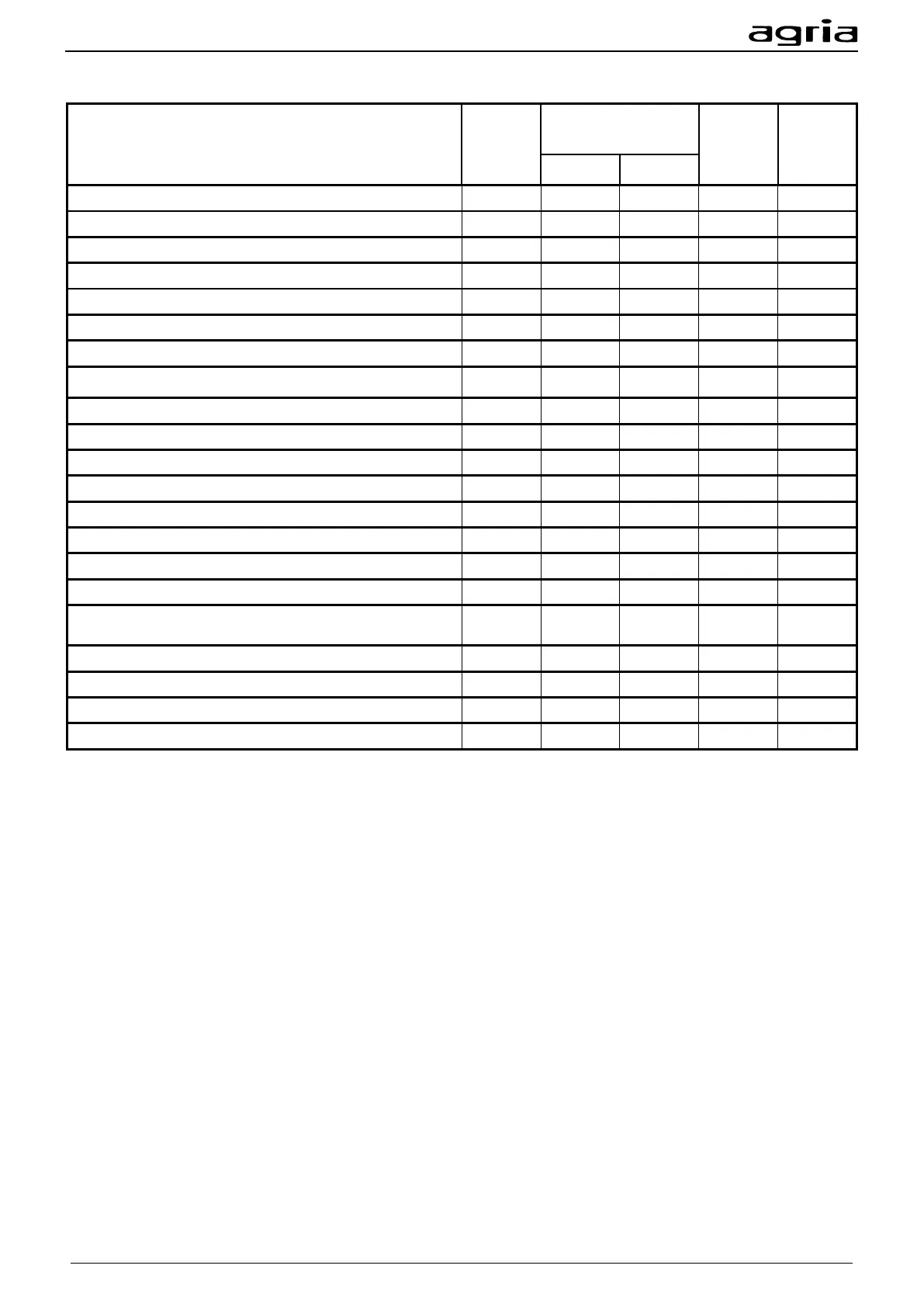

Inspection and Maintenance Overview

After every... operat-

ing hours (h)

Wire mesh filter, clean electrical box

Emergency stop switch machine: Check function

Emergency stop switch remote control: Check function

Check operating functions of remote control

Check nuts and bolts for tightness

Check crawler track tension

Check oil level hydraulic system

Lubricate grease nipple hydraulic cylinder

Check crawler tracks for damage

Check V-belt for damage and belt tension

Check heat sink/air filter box for soiling

Clean heat sink/air filter box

Check surrounding area of hydraulic pump for soiling

Clean surrounding area hydraulic pump

Visual inspection of three-point mounting bracket

Check screw connections of the rechargeable batteries for tightness

and retighten if necessary

Check cables and electrical system for damage

A = before each start-up

J = at least yearly

K = inspection and maintenance tasks can be performed by the operator

W = maintenance tasks that are to be performed by a specialist workshop

(W) = maintenance tasks that are performed by a specialist workshop during the first maintenance

W1 = once a year

W6 = every 6 years

! = pay attention to execution

Loading...

Loading...