26

StorageMethod1.

Aftereachuse,storethemachineasfollows:

(1) Parkthemachineonafirm,levelsurface.

(2) Takealltoolsandmaterialsfromthe

platform.

(3) Retractandlowertheboomfully.

(4) Shutdowntheenginebyturningoffthe

keyswitch,removethekeytoprevent

usingthemachinewithoutpermission,

andstoreitsuitably.

(5) Chockthewheels.

(6) Performthedailymaintenance.

DailyMaintenance2.

Onlydailymaintenanceitemsthatspecified

inthismanualshallbeperformedbythe

operator.

Refuelthemachine2‒1

WARNING

• Ensurethemachineonlyinawell

ventilatedareaawayfromopenframe

andothersourcesofignition.

• Neverremovethefuelcapwiththe

enginerunning.

• Neverrefuelwiththeenginerunning.

Beforeusingthemachineensurethereis

enoughfuelforexpecteduse.

(1) Makesuretheengineandallsystems

areturnedoffandtheemergencystop

buttonsaredepressed.

(2) Removethefuelcap.

(3) Pourfuelintothefueltankcarefully.

(4) Tightenthefuelcapsecurely.

DieselFuelSpecifications2‒1‒1

Dieselfuelshouldcomplywiththefollowing

specifications.Thetablelistsseveralworldwide

specificationsfordieselfuels.(Seetable7‒1)

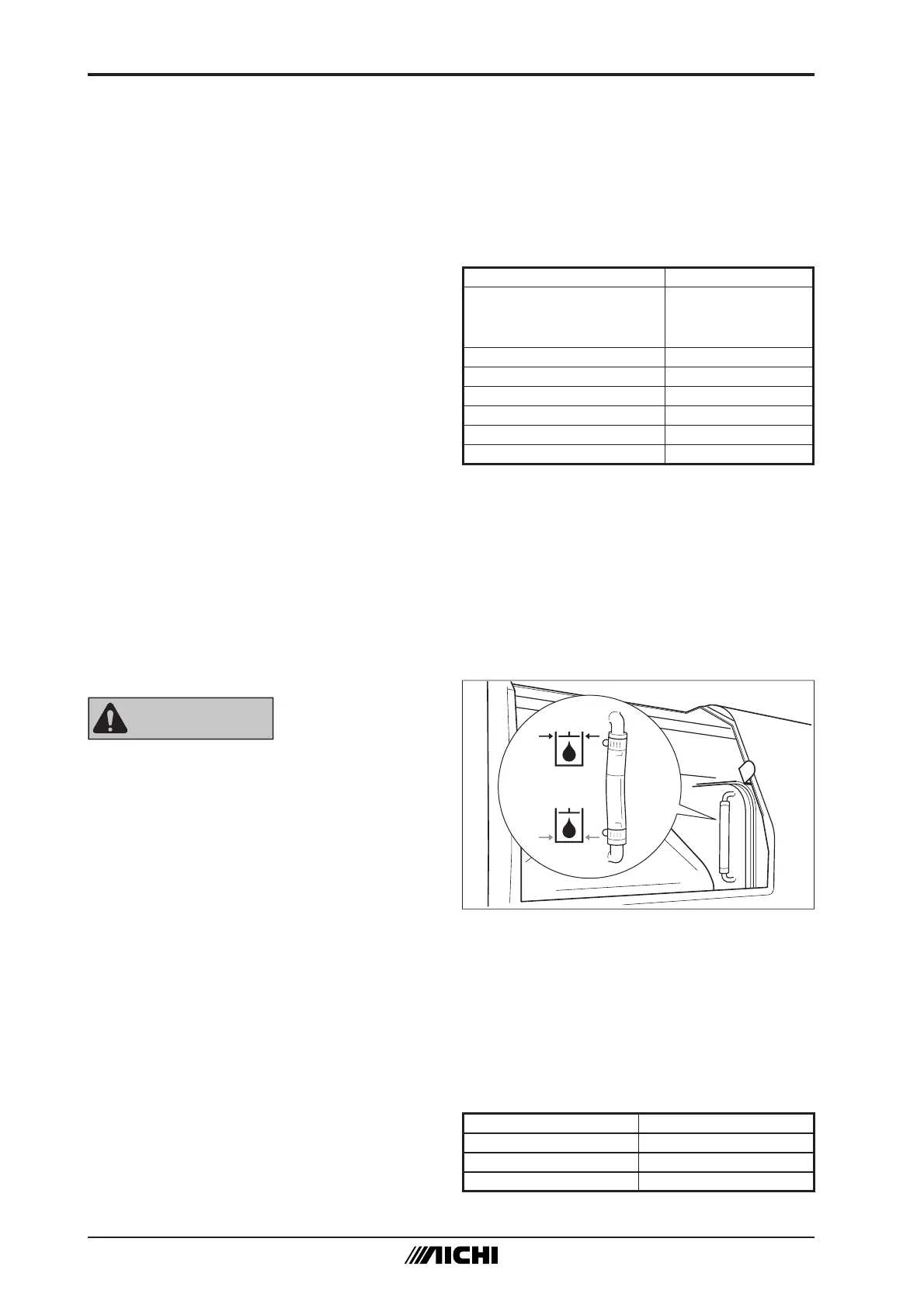

DieselFuelSpecification Location

ASTMD975

No.1DS15,S500

No.2DS15,S500

USA

EN590:96 EuropeanUnion

ISO8217DMX International

BS2869-A1orA2 UnitedKingdom

JISK2204GradeNo.2 Japan

KSM-2610 Korea

GB252 China

table7‒1

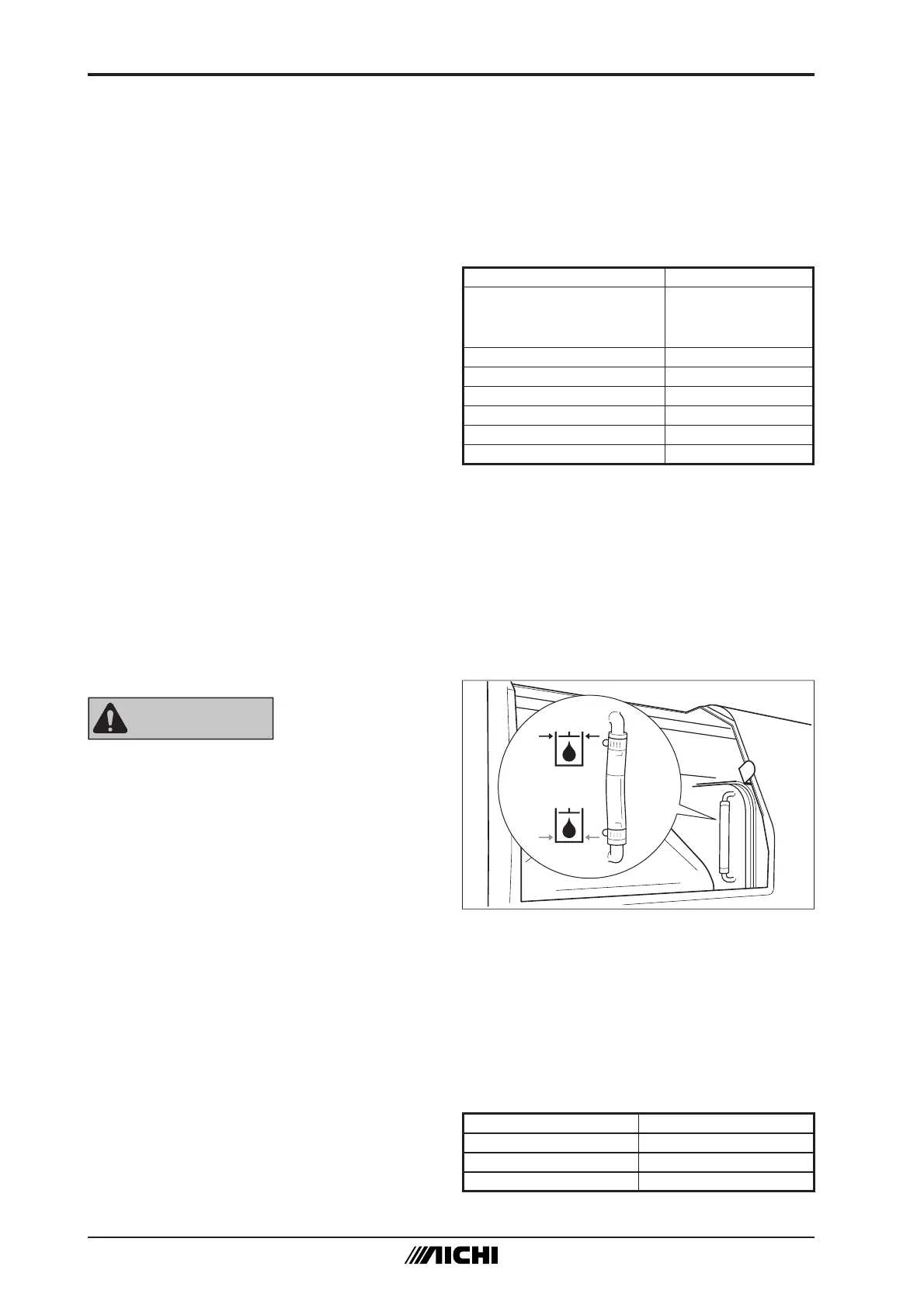

ChecktheHydraulicOilLevel2‒2

Maintainingthehydraulicoilatsufficientlevel

isveryimportantforthemachineoperation.

Deficientofthehydraulicoillevelcandamage

hydraulicparts.Dailychecksfromtheoillevel

gauge(fig.7‒1)canconfirmthechangeof

thehydraulicoillevelthatmightshowthe

hydraulicsystemproblems.

M082M100

fig.7‒1

(1) Makesurethemachineislevel.

(2) Makesuretheboomisretractedand

loweredfully.

(3) Checktheoillevelgaugelocatedonthe

sideofthehydraulicoiltank.

(4) Addthehydraulicoilifnecessary.

HydraulicOilSpecifications2‒2‒1

Manufacturers Hydraulicoil

Shelloil TellusoilT22

Essooil UnipowerXL22

Mobiloil HydraulicoilK22

table7‒2

Maintenance

Loading...

Loading...