29

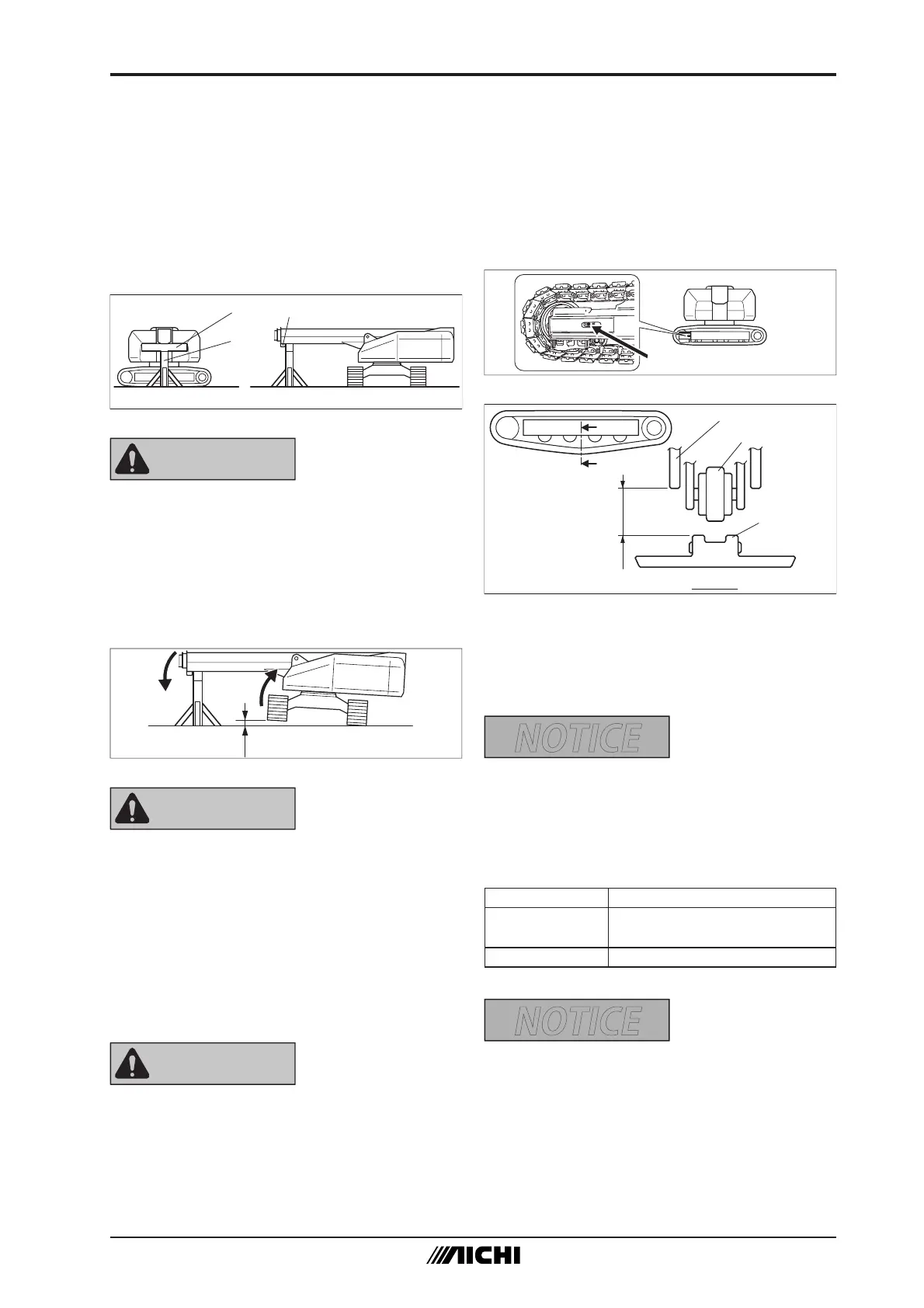

Settheboomstand(fig.7‒6,B)andthe

woodblock(fig.7‒6,A)topropupthefirst

boomend.Usethewoodblockthatiswider

thanthewidthoffirstboomend.

Avoidthetie-downring(fig.7‒6,C),and

centerthefirstboomendonthewood

block.

Makesurethestandisstable.

M085K102

(A)

(B)

(C)

fig.7‒6

WARNING

Fixatethestandwithbracemembersso

thatthestanddoesnotfalloverduring

operation.

Usingthelowercontrols,lowertheboom

toliftupthetrack30〜50mmabovethe

ground.(fig.7‒7)

M085K201

30mm~50mm

fig.7‒7

WARNING

Donotliftupthetrackmorethan

50mmabovetheground.Liftingupthe

trackmorethanneededcouldcausethe

machinetobecomeunstable.Deathor

seriousinjurycouldresult.

Pushintheemergencystopbuttontostop

theengine.Turnthekeyswitchto“OFF”and

removethekey.

WARNING

Neverleavethekeyinthekeyswitch

whenadjustingthetensionofthe

tracks.Someonemayaccidentallystart

theenginewithoutrealizingitwhile

adjustingthetensionofthetracks.Such

accidentscouldresultinaseriousinjury.

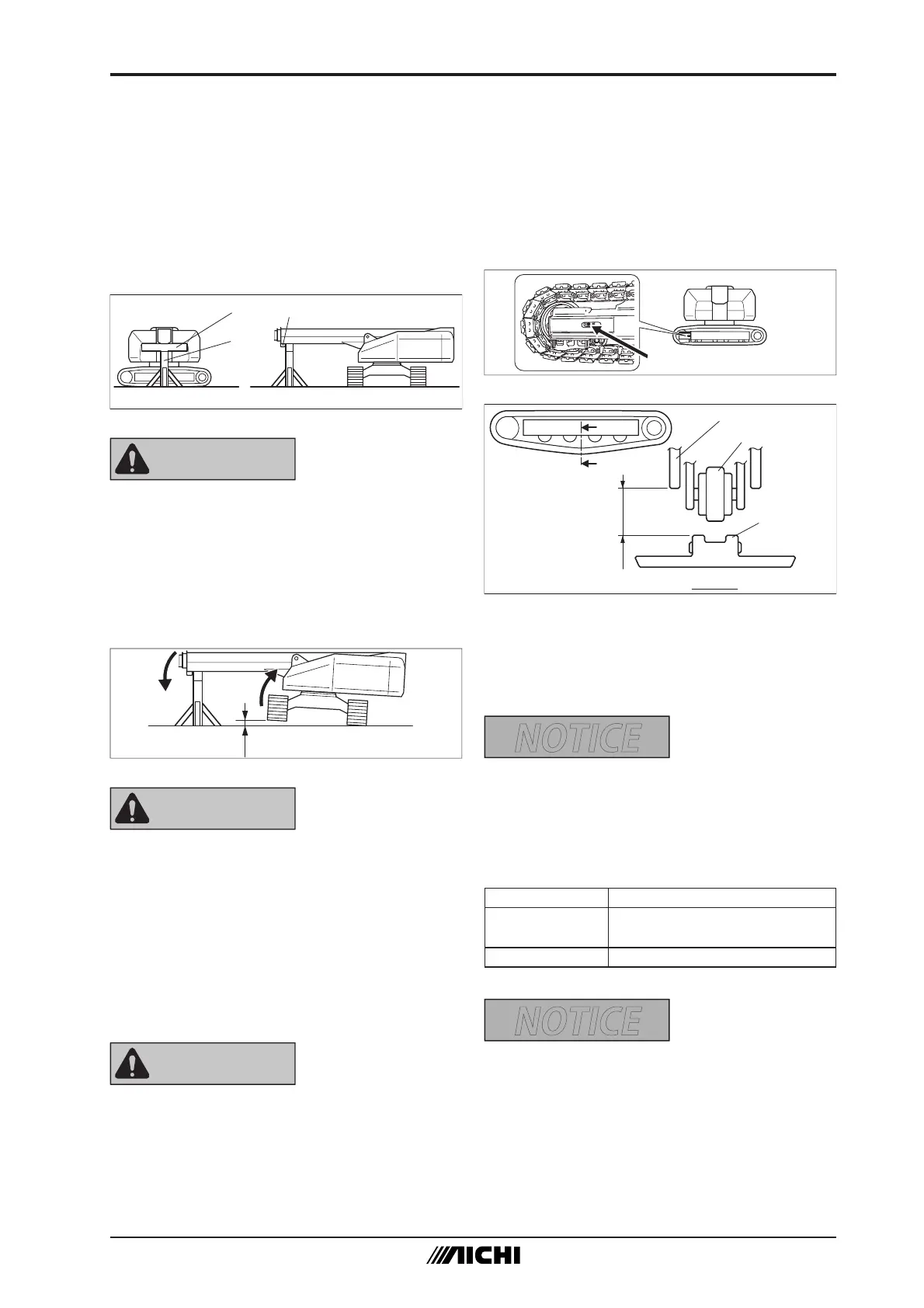

Agreasefitting(fig.7‒8,A)islocatedon

therightandleftsidesofthechassisframe.

Supplygreasetothegreasecylinderthrough

thegreasefittingtoadjustthetensionofthe

track.Adjustthetensionofthetracksothat

thereis115〜125mmofslackbetweenthe

chassisframeandtracklink.(fig.7‒9)

M085K401

(A)

fig.7‒8

M085K320

Trackroller

Chassisframe

115mm~125mm

A−A

Tracklink

A

A

fig.7‒9

Afteradjustingoneside,rotatetheboom

180°andadjusttheothersideinthesame

manner.

NOTICE

Itisimportanttoadjustthetensionof

leftandrighttracksequally.

AdjustmentInterval3‒2‒2

Adjustthetensionofthetracksatthe

followingtimeintervals.

Interval

Firsttimeon

newmachine

After10〜20hours

Thereafter Every800hoursor6months

table7‒3

NOTICE

Confirmthenumberofhoursinservice

bythehourmeter.

Loading...

Loading...