7.2.3.1 Biodegradable hydraulic oil (Optional)

At the request of the customer, the machines can be supplied with biodegradable hydraulic oil compatible with the

environment. Biodegradable hydraulic oil is completely synthetic, without zinc, non-polluting and highly efficient with

saturated ester base, combined with special additives. The machines with biodegradable oil use the same component

parts as standard machines, but the use of such type of oil is best taken into account from machine construction.

In case of wanting to change from mineral-oil based hydraulic oil to “bio” oil, the following procedure must be followed.

7.2.3.2 Emptying

Empty the hot hydraulic oil for entire system operation (oil tank, cylinders, large-volume pipes).

7.2.3.3 Filters

Change the filtering inserts. Use standard filters as indicated by the manufacturer.

7.2.3.4 Washing

After completely emptying the machine, fill with a nominal quantity of “bio” hydraulic oil.

Start the machine and perform all work movements at low revs for at least 30 minutes.

Drain the liquid from the system as indicated at 7.2.3.

Warning: During the entire washing procedure, avoid air entering the system.

7.2.3.5 Filling

After washing, fill the hydraulic circuit, bleed and check the level.

Bear in mind that contact of fluid with the hydraulic pipes can cause swelling.

Also remember that contact of fluid with the skin can cause reddening or irritation.

Also use suitable PPE during these operations (e.g., protective eyewear and gloves).

7.2.3.6 Commissioning / check

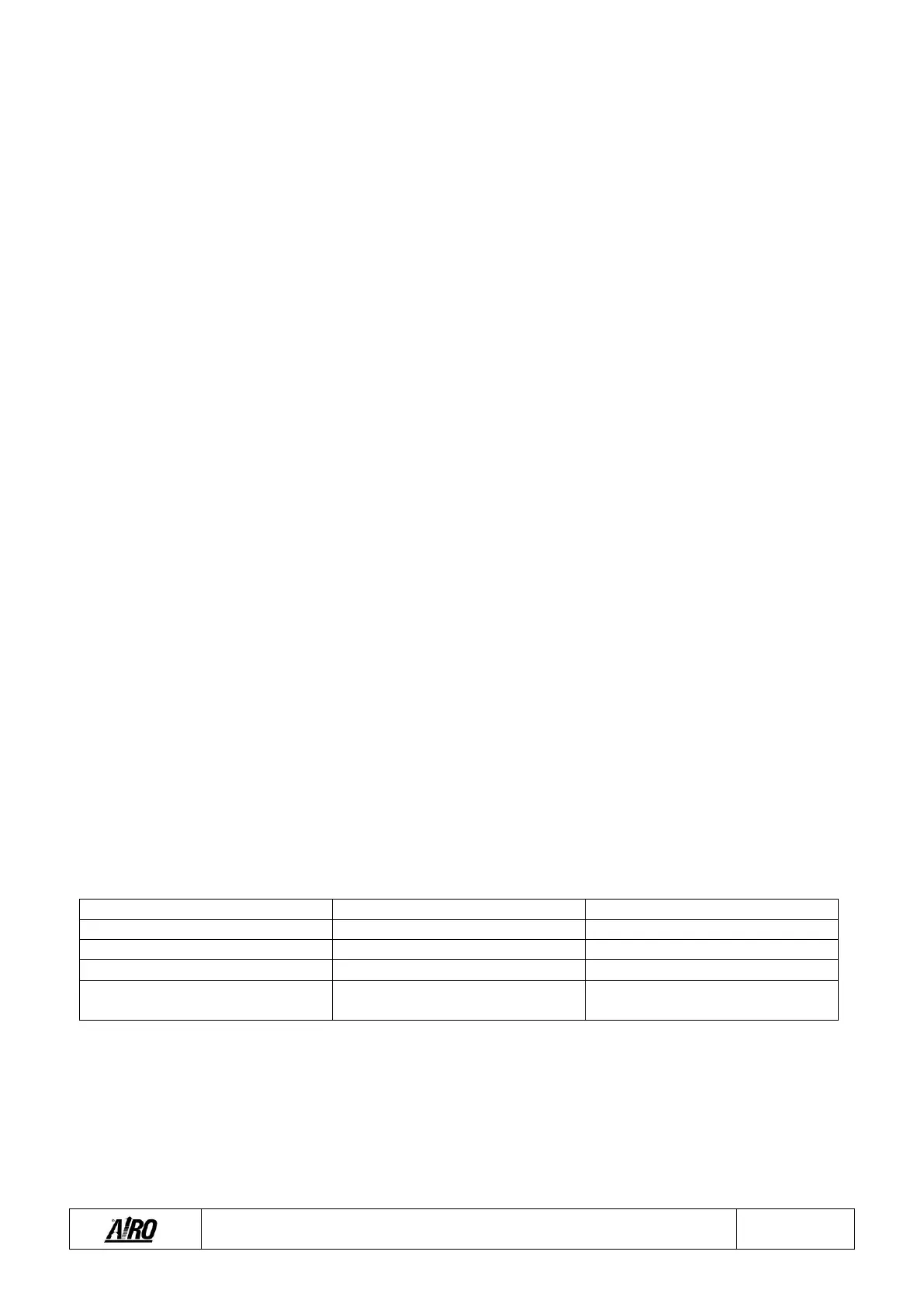

“Bio” oil behaves regularly, but it must be checked by taking a sample at set intervals according to the indications

provided below:

The fluid state is therefore constantly monitored, thus allowing its use until its features decay. Normally, in the absence

of contaminating agents, the oil is never completely changed, but only occasionally topped-up.

The oil samples (at least 500ml) must be taken with the system at operating temperature.

It is recommended to use new and clean containers.

The samples must be sent to the “bio” oil supplier.

For more dispatch details, contact Your nearest distributor.

Copies of the analysis report must be kept in the check register. This is mandatory.

Loading...

Loading...