Chapter 2

Installation/Wiring

2–42

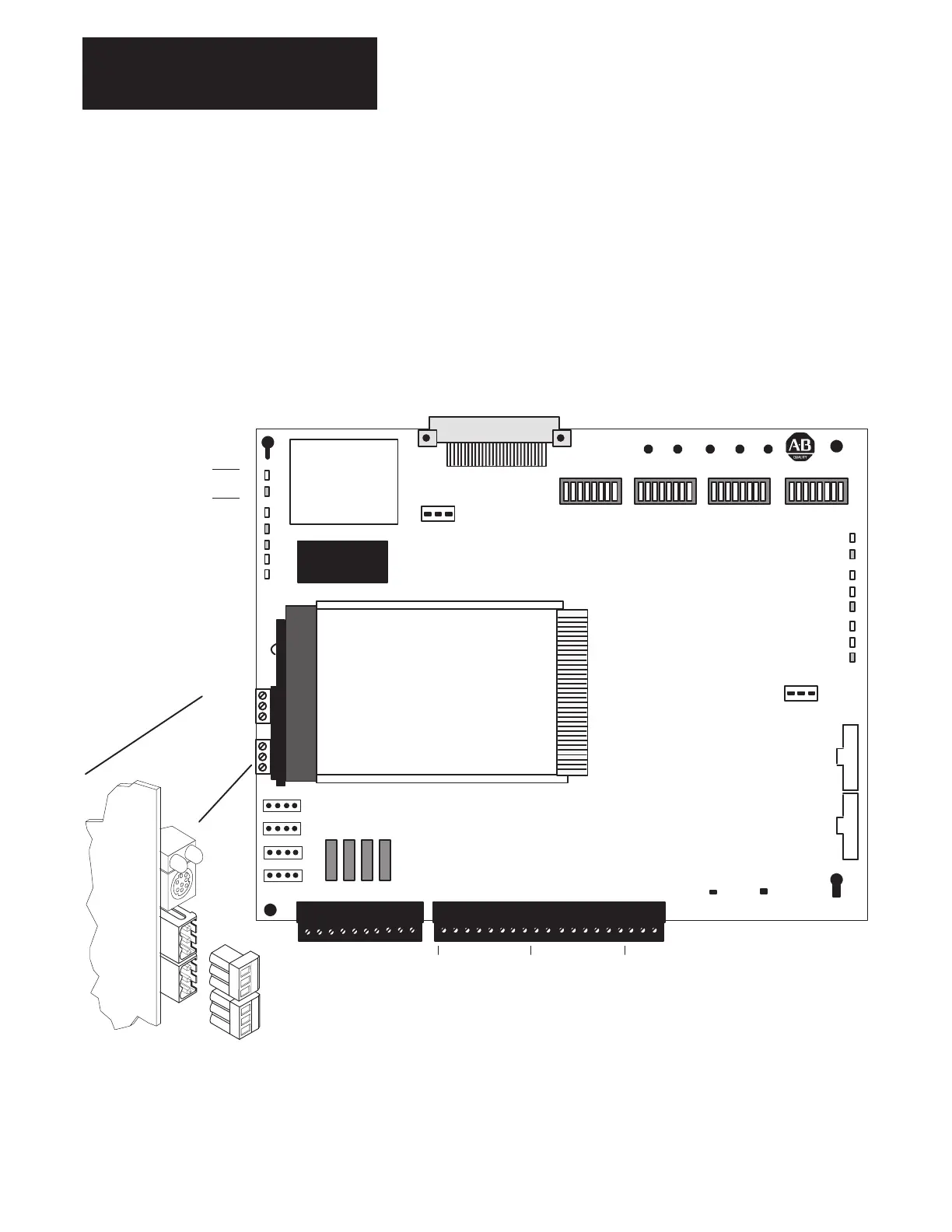

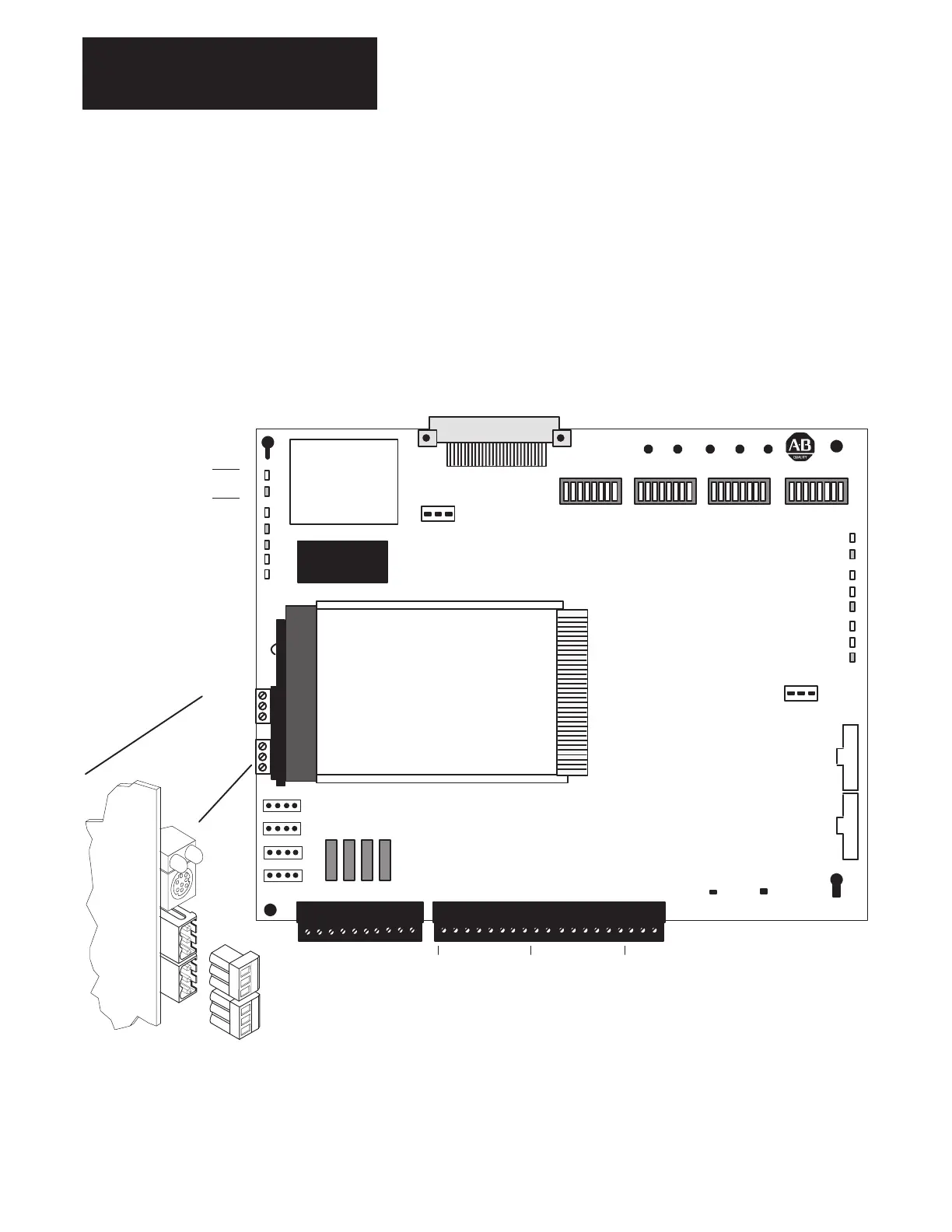

PLC Communication Adapter Board Control and Signal Wiring – When installing and wiring the PLC

Communication Adapter Board, you need to deal with the following issues:

• Control and Signal Wiring

• Jumper Settings for I/O Circuits

If your 1336 FORCE Drive is equipped with a PLC Comm Adapter Board,

terminal blocks TB20 & TB21 located at the bottom center of the PLC

Comm Board (Figure 2.29) are used for control and signal wiring (Drive

Permissives). Connector TB21 provides the interface for Analog Input and

Output reference signals as detailed in Figure 2.30.

Figure 2.29.

PLC Comm Board Connections

AP

Status

LANGUAGE

MODULE

DP Status

1

CH A High

J5

TP1

Port 1

DOMINO

ADAPTER

RIO

Channel A

Communication Modes

U2 U3 U4 U5

10

TB20

TB21

119

CH A Low

CH B Low

CH B High

D3

D6

D8

D10

D12

D13

D14

D15

CH A

Status

CH B

Status

J7

D1

D2

Port 2

TP2

TP3

TP4

TP5

ADC InputsDAC Inputs

J1

Main Control

Interface

Drive Permissives

J4

J3

120 V

RIO

Channel B

BRAM

Enable

Ref

D4

D5

Fault Out

Ext Fault

D7

Norm Stop

Motor Thermo

D9

Drive Enable

D11

24 V

120 V 24 V

120 V 24 V

120 V 24 V

J11

J10

J9

J8

Drive En

M Therm

N Stop

X Flt

EN DIS

Fuse

1 – 4

TP24

+10V Ref

TP25

–10V Ref

↑

ON

↑

ON

↑

ON

↑

ON

DGND +5V +15V –15VAGND

NOTE: For more information on the PLC Communication Board

including LEDs and Jumpers, refer to the PLC Communication User

Manual 1336 FORCE 5.13.

CHANNEL A

SHIELD

CHANNEL B

2

1

SHIELD

2

1

The maximum and minimum wire size accepted by TB20, TB21, Channel

A and Channel B is 3.3 and 0.06 mm

2

(12 and 30 AWG). Maximum

torque for these terminal blocks is 0.79 N–m (7 lb. – in.). Only copper

wire may be used.

Loading...

Loading...