16 Rockwell Automation Publication 2080-UM004D-EN-E - March 2018

Chapter 2 Install and Wire Your Module

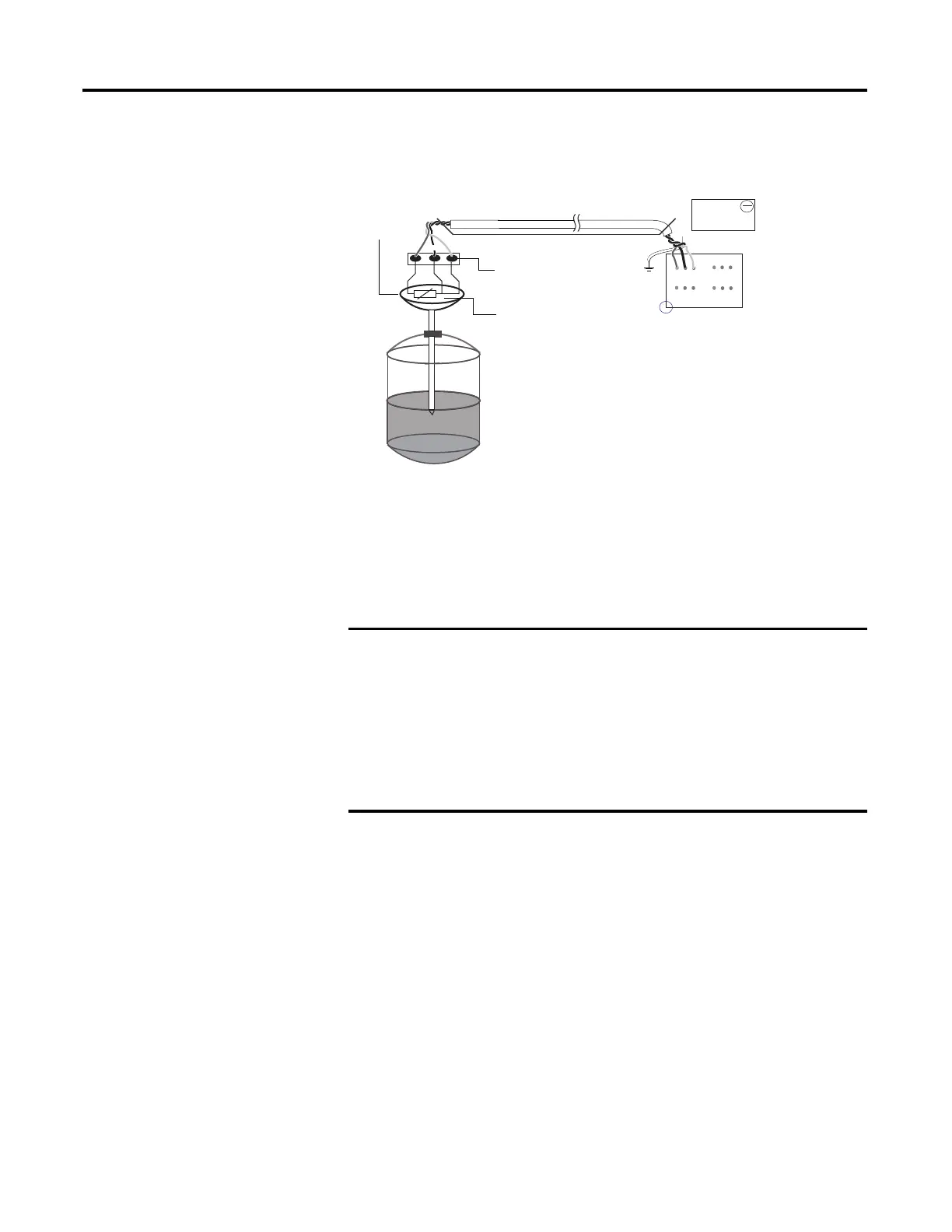

Wire the RTD Module and RTD Sensor in the Field

The RTD sensing element should always be connected between terminals B1(+)

and B2(-) for channel 1, and A1(+) and A2(-) for channel 0 in the module.

Terminals B3 and A3 should always be shorted to B2 and A2, respectively, to

complete the constant current loop. Mismatch in wiring can cause erroneous,

over, or underrange readings.

Cabling used with the 2080-TC2/RTD2 modules have to be shielded

twisted cores with the shield wire shorted to chassis ground at controller

end. It is advisable to use 22 AWG wires to connect the sensors to the

module. Use sensors dipped in oil-filled thermowells for stable and

uniform readings. Recommended cable type: Alpha wire P/N 5471C.

Performance is dependent on the application. For better noise immunity,

cable length should ideally be less than 3 m because the plug-ins are

non-isolated. For longer cable length requirements, use the 2085

expansion I/O modules instead.

1

2

3

1 2 3 4 5 6

1 2 3 4 5 6

2080-RTD2

B

A

Red

Green

Black

Blue

Red

Blue

Black

Process

temperature

Measurement

Shielded twisted wire cable

Field screw

junction box

3-wire

RTD

Oil filled

thermowell

45779

3-wire RTD shown

Cable tray/conduit

Loading...

Loading...