1-6 Installation/Wiring

The drive Safety Ground - (PE) must be connected to system

ground. Ground impedance must conform to the requirements of

national and local industrial safety regulations and/or electrical codes.

The integrity of all ground connections should be periodically checked.

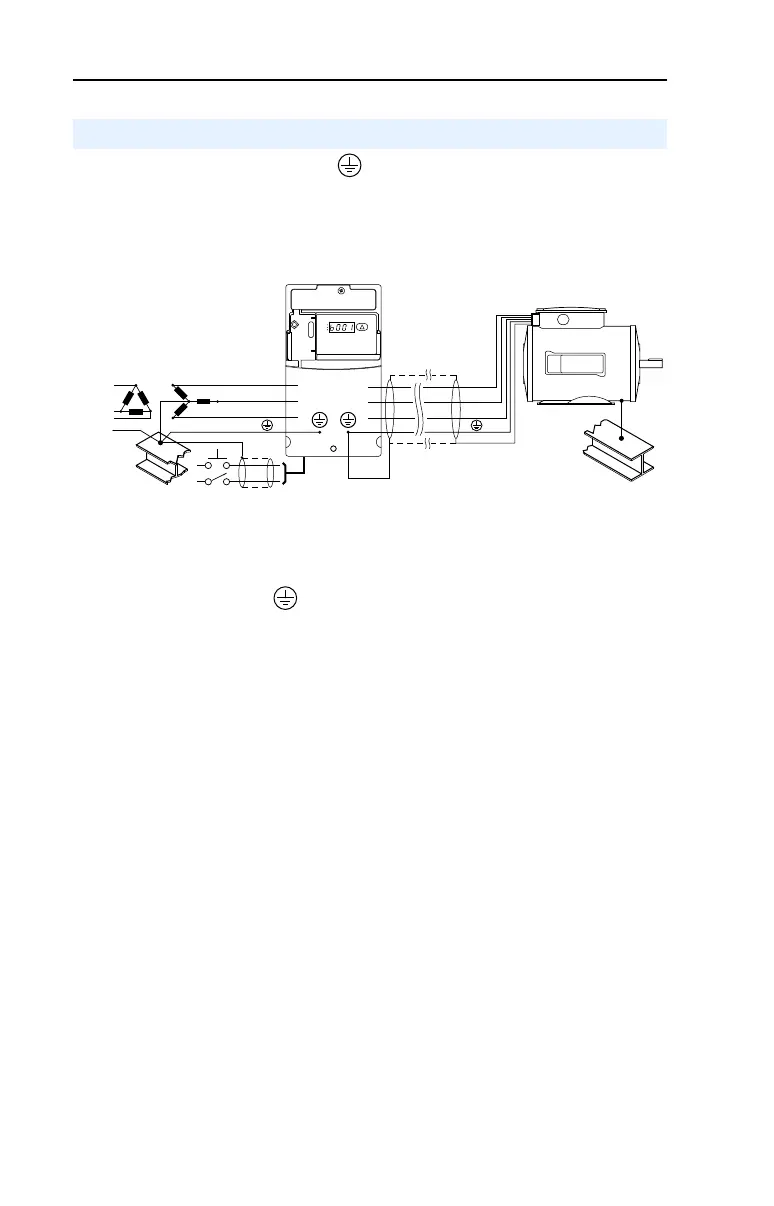

Figure 1.3 Typical Grounding

Ground Fault Monitoring

If a system ground fault monitor (RCD) is to be used, only Type B

(adjustable) devices should be used to avoid nuisance tripping.

Safety Ground - (PE)

This is the safety ground for the drive that is required by code. One of

these points must be connected to adjacent building steel (girder, joist), a

floor ground rod or bus bar. Grounding points must comply with national

and local industrial safety regulations and/or electrical codes.

Motor Ground

The motor ground must be connected to one of the ground terminals on

the drive.

Shield Termination - SHLD

Either of the safety ground terminals located on the power terminal

block provides a grounding point for the motor cable shield. The motor

cable shield connected to one of these terminals (drive end) should also

be connected to the motor frame (motor end). Use a shield terminating or

EMI clamp to connect the shield to the safety ground terminal. The

conduit box option may be used with a cable clamp for a grounding point

for the cable shield.

When shielded cable is used for control and signal wiring, the shield

should be grounded at the source end only, not at the drive end.

General Grounding Requirements

SHLD

U/T1

V/T2

W/T3

R/L1

S/L2

T/L3

RUN

REV

FAULT

Loading...

Loading...