22 Rockwell Automation Publication 750-IN100B-EN-P - July 2017

Chapter 2 Receiving, Handling, and Storage

Handling

Two methods of handling PowerFlex 755T products within the receiving

facility are acceptable.

• Transport by lift truck

• Overhead lifting (crane or hoist)

PowerFlex 755T products must be handled in the upright vertical position.

Failure to comply with this requirement can lead to internal component and

enclosure damage.

The following guidelines are provided to help avoid personal injury and

equipment damage during handling and to help stabilize the product during

transport to the installation site.

• Keep the product bolted to the shipping skid to minimize possibility of

tipping.

• The factory installed structural angles must remain secured to the

enclosure during handling. Structural angles provide lift points and help

prevent flexing of the enclosure during handling.

• Handle the PowerFlex 755T product carefully to avoid damage to the

enclosures and paint.

• Keep the product in an upright position. PowerFlex 755T products,

frame 8 and larger, are not to be tipped or laid flat during handling.

Before moving the product, verify that the route is clear of all obstructions and

that other workers are a safe distance away.

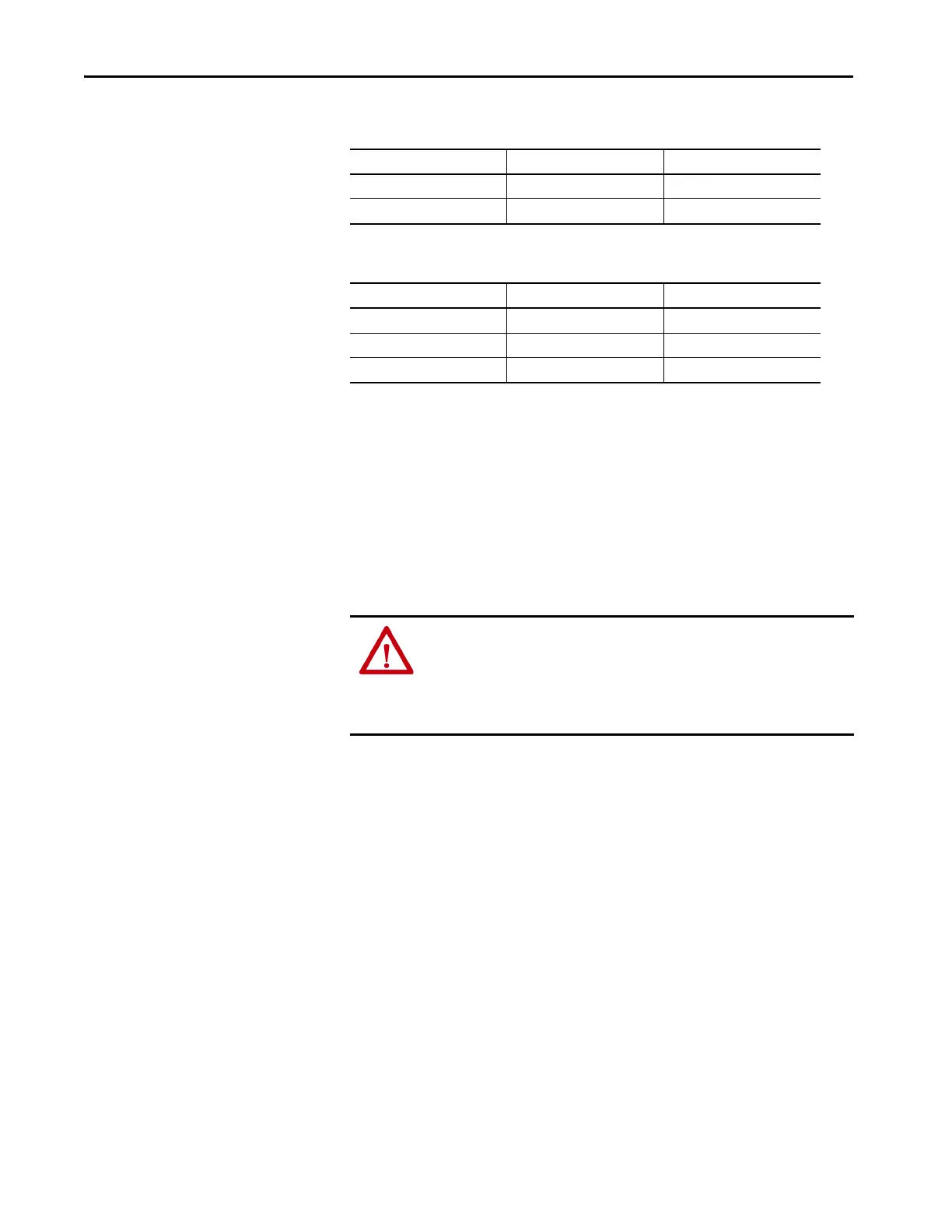

Approximate Maximum Entry and Exit Wiring Bay Weights

Bay Width mm (in.) Maximum Weight kg (lb) Maximum Ship Weight kg (lb)

400 (15.7) 102 (225) 129 (285)

800 (31.5) 242 (535) 309 (682)

Approximate Maximum IP54, UL Type 12 Roof Fan Assembly Weights

Bay Width mm (in.) Maximum Weight kg (lb) Maximum Ship Weight kg (lb)

400 (15.7) 25 (55) 30 (66)

600 (23.6) 25 (55) 32 (71)

800 (31.5) 50 (110) 57 (126)

ATTENTION: Follow local codes and guidelines in addition to your company

safety procedures when you handle PowerFlex 755T products.

To avoid personal injury and structural damage to the PowerFlex 755T product,

never attempt to lift or move the equipment by any means other than those

listed in this publication. PowerFlex 755T products are top- and front-heavy.

Loading...

Loading...