103ARX 23-2 T4i, ARX 26-2 T4i

OPERATING MANUAL

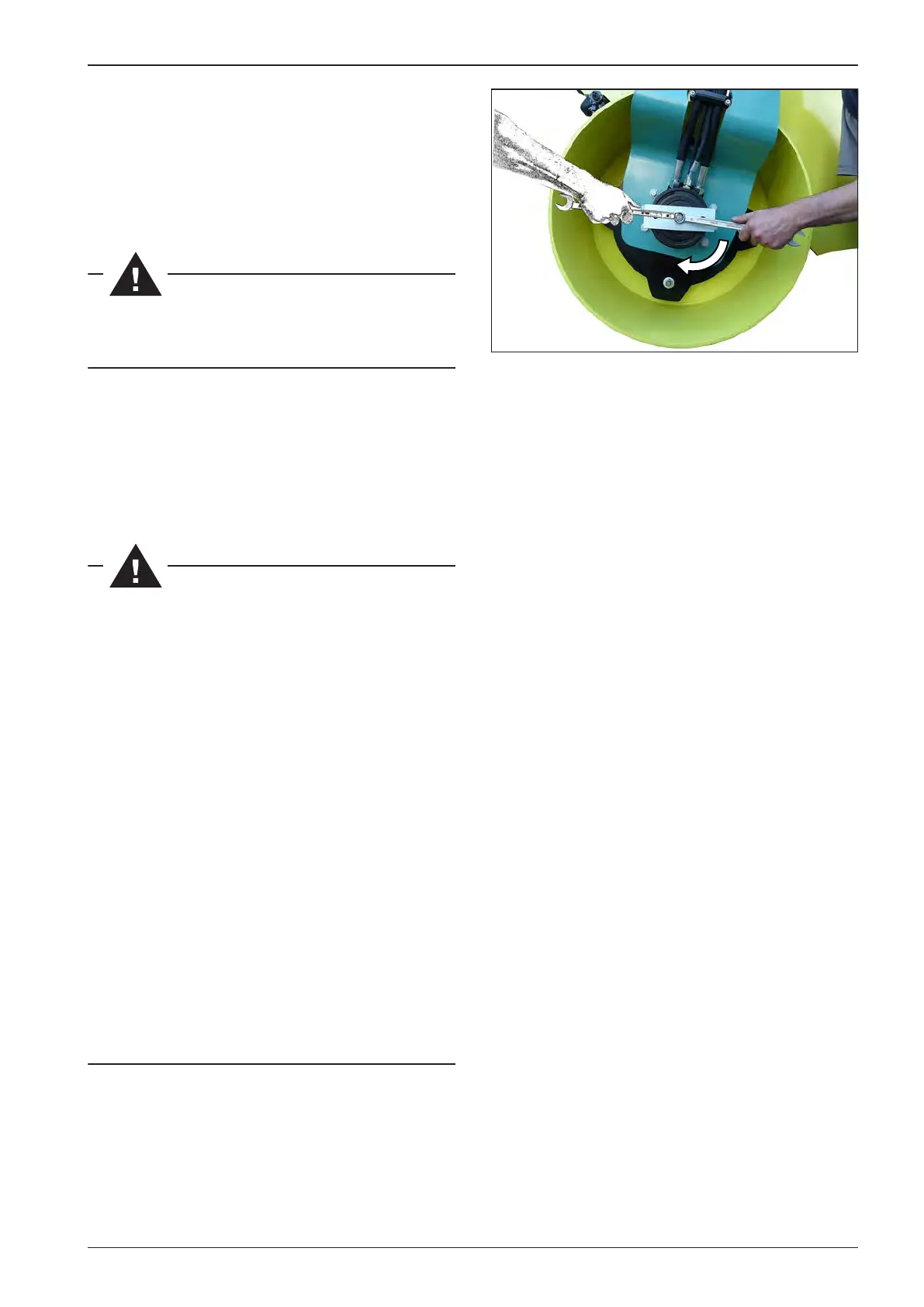

Mount abrake disc on the front drum travel hydraulic motor.

Tighten the screw by half aturn.

Note

Repeat the same procedure for the hydraulic motor of the rear

drum travel.

When the towing is completed, return the machine into

its original shape using the reverse procedure.

Towing procedure

• Secure the articulation joint of the machine against tilting.

• Attach the tow ropes or tow bars.

• Pull out the machine from the danger area.

The towed machine must be attached to both tow lugs.

For towing, use undamaged tow ropes or tow bars of

asucient capacity 1.5 × higher than the weight of the

towed vehicle. Do not use achain for the towing.

It is necessary to maintain the minimal angular deviation

from the direction of towing. The maximum possible an-

gular deviation is 30°.

The towing movement must be smooth. Do not exceed

the towing speed by more than 1 km/hour (0.6mph).

Tow the roller at the shortest distance possible – to res-

cue when it gets stuck or to remove when it is broken and

obstructing. Do not tow for adistance exceeding 10 m

(11yd).

The towing machine should correspond with its size to

the damaged machine. It must have asucient traction

power (output), weight, and brake eect.

While towing downhill using arope, another towing ma-

chine must be connected to the rear part of the damaged

machine. In this way you can prevent an uncontrolled

motion of the damaged machine.

No person may be on the towed machine!

Do not touch hot parts of the machine, there is aburn

hazard!

Loading...

Loading...