119ARX 23-2 T4i, ARX 26-2 T4i

h

1/4

2/4

1

3/4

9V

11V

15V

13V

3.6 Lubrication and maintenance operations

The lubrication and maintenance chart contains tasks and in-

structions that must be followed at certain intervals. If the table

contains two intervals of mandatory maintenance, e.g. every

1000 hours of operation or 1 year, always use the interval that

occurs rst.

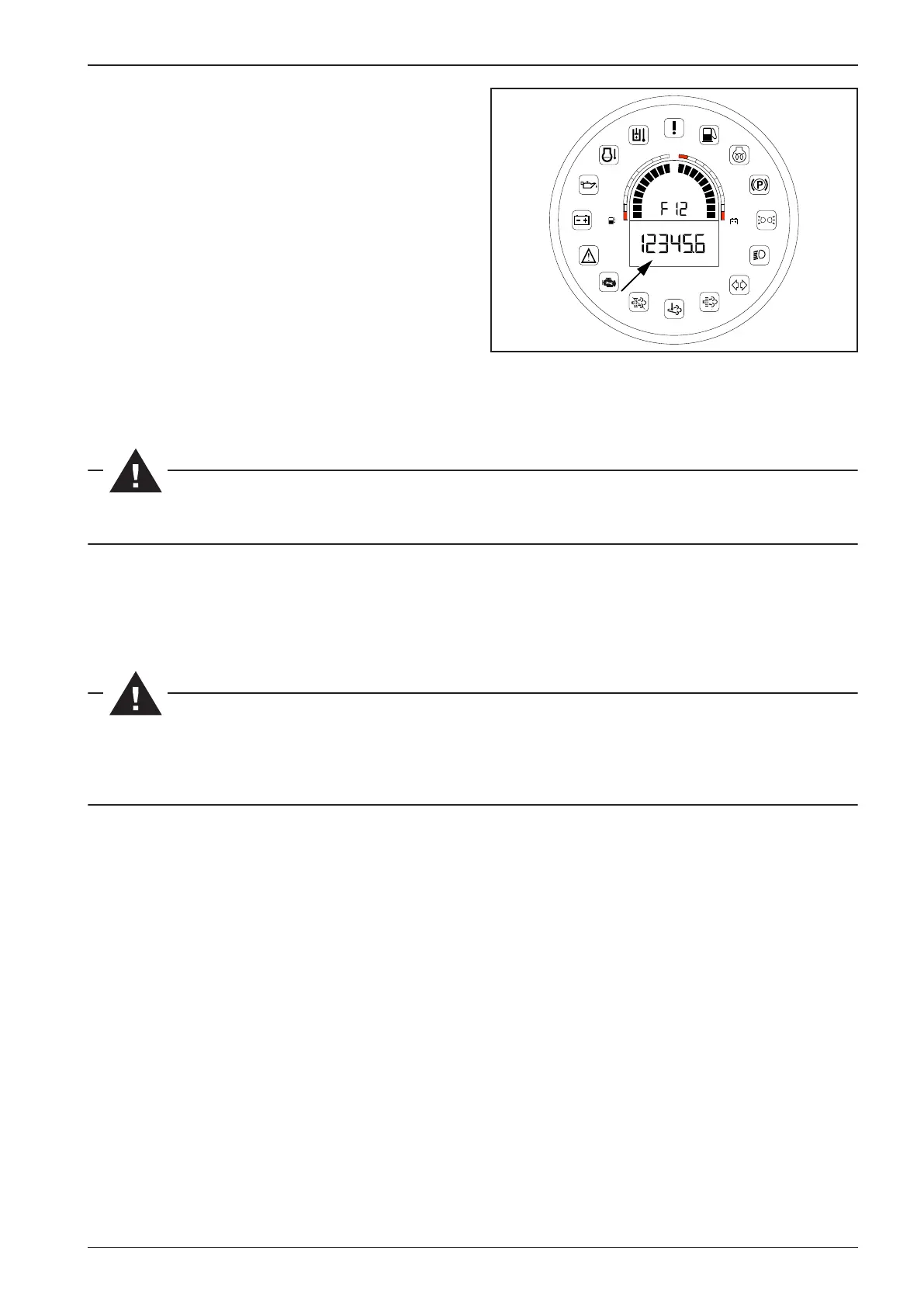

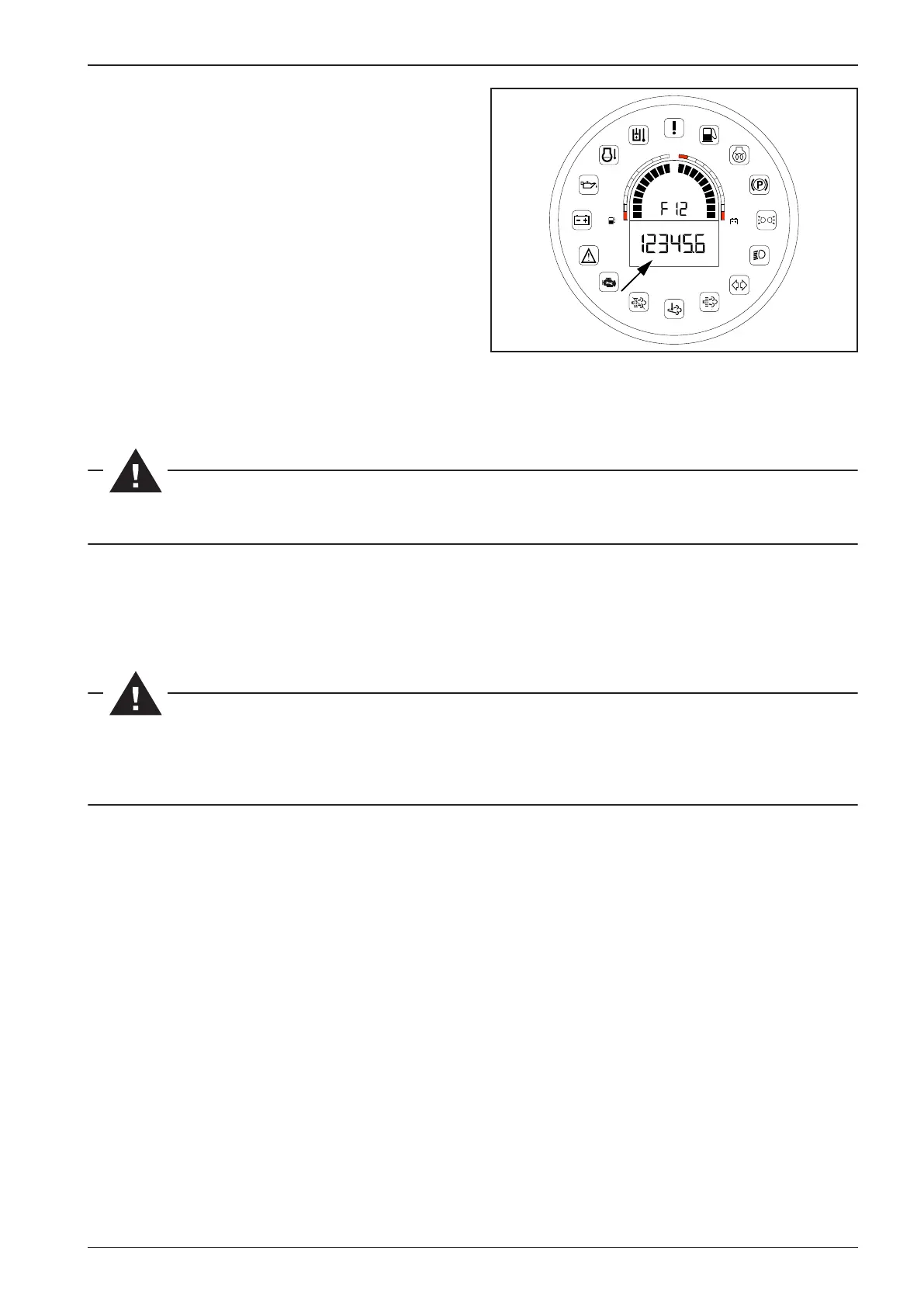

The worked hours can be determined by daily reading of the

data on the worked hours counter.

This manual includes only basic information about the engine; the other data are given in the operation and maintenance manual,

which is apart of documentation supplied together with the machine.

Follow also instructions given in the engine operating and maintenance manual!

Retighten removed or loosened bolts, plugs, threaded joints in the hydraulic system, etc. with the tightening torque specied in tables

in the chapter 3.6.51 unless adierent value is given for the respective operation.

Carry out maintenance works with the machine placed on aat, solid surface and secured against any spontaneous

movement, always with the engine o, and the key removed from the ignition box and with the disconnected electrical

installation (unless required otherwise).

After the rst 50 hours of operation of the new machine or after its general overhaul, carry out the following operations ac-

cording to Chapter:

3.6.22 Engine oil change

After the rst 500 hours of operation of the new machine or after its general overhaul, carry out the following operations ac-

cording to Chapter:

3.6.33 Filter hydraulic oil change

Loading...

Loading...