22

Operator's instructions

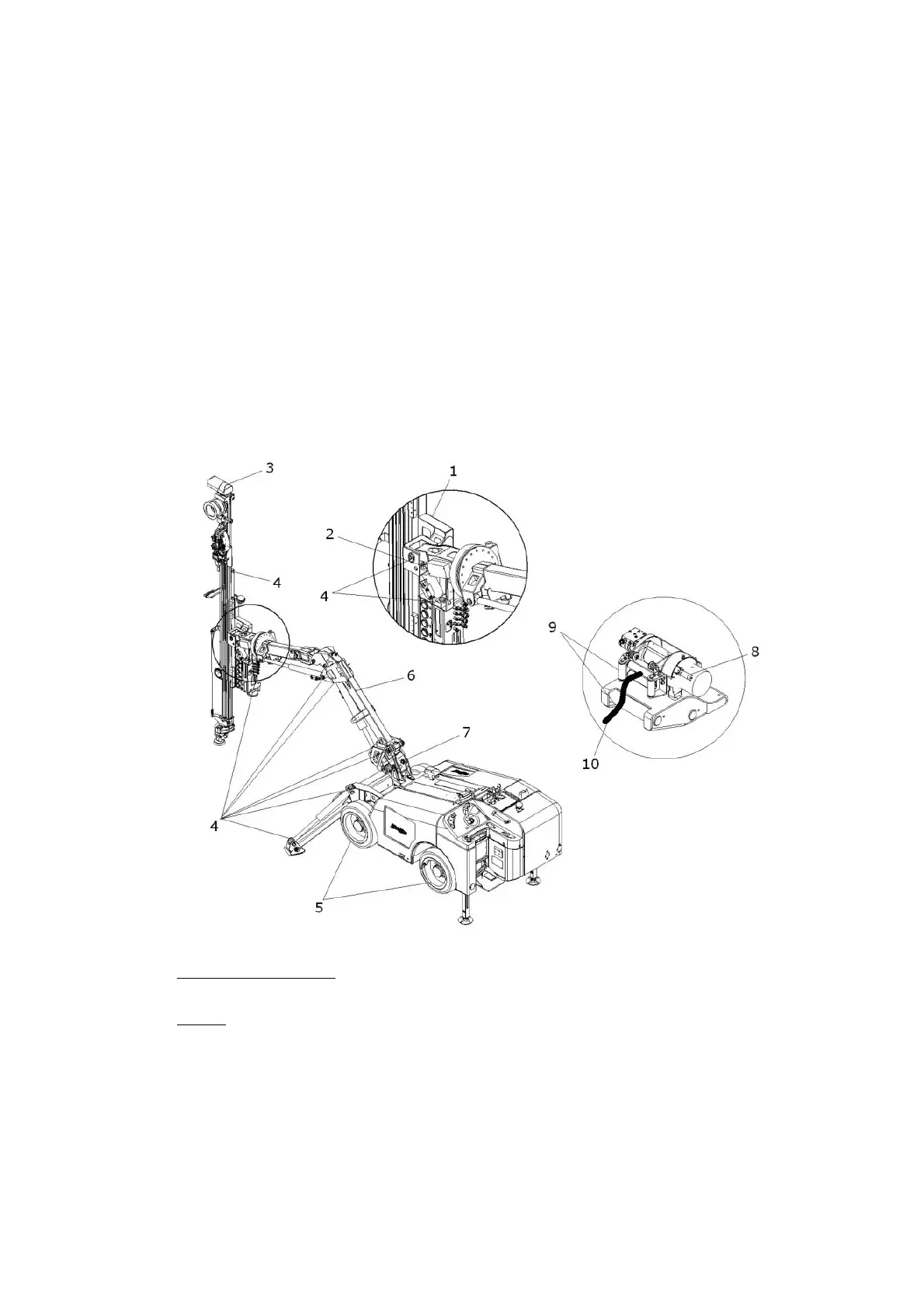

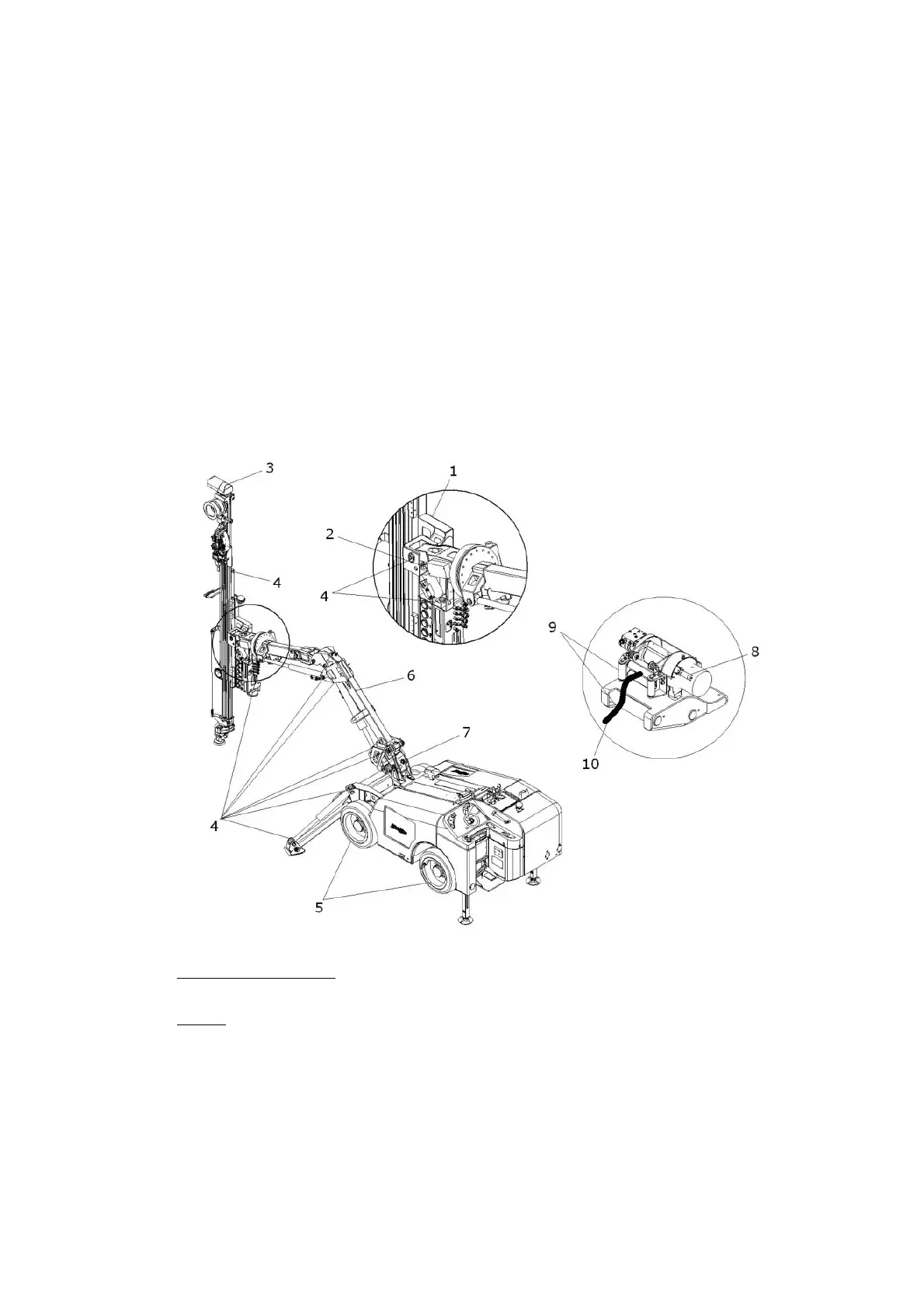

3. Daily checks

Before each shift starts an extra and thorough visual safety check should be carried

out in order to detect:

• Damage that could give rise to structural weakness or cracks.

• Wear that could have the same consequences.

• Cracks or fractures in materials or welded joints.

If the drill rig has been subjected to abnormally high stresses, vital load-bearing com-

ponents may have been damaged. From a safety viewpoint, it is therefore especially

important to check the following points (see illustration: Check points).

Check points

Figure: Check points

Table:

1 Feed holder with attachment 6 Boom

2 Boom head 7 Boom support

3 Feed motor

8 Release/engage mechanism

4 Cylinder brackets 9 Winch with brackets

5 Wheels 10 Winch wire rope with hook

Loading...

Loading...