NOTICE Total damage to the hydraulic

attachment

Polluted hydraulic lines and connections may

enable sand, fragments of material and dirt to

penetrate the hydraulic attachment and damage it

completely.

►

Clean the hydraulic lines and connections

before connecting the hydraulic hoses. Lay all

hydraulic hoses so that they are torsion-free.

◆

Install the pressure and tank hoses.

◆

Connect the pressure and tank hoses.

◆

If no quick couplings are used, open the shut-off

valves in the installation at the boom.

◆

Switch on the carrier.

◆

Let the hydraulic oil run through the carrier oil

filter for approx. three minutes to make sure

that the hoses are clean.

◆

Switch off the carrier.

◆

Depressurise the hydraulic system according to

the manufacturer's safety and operating

instructions for the carrier.

◆

If no quick couplings are used, close all shut-off

valves in the installation at the boom.

◆

Disconnect the pressure and tank hoses.

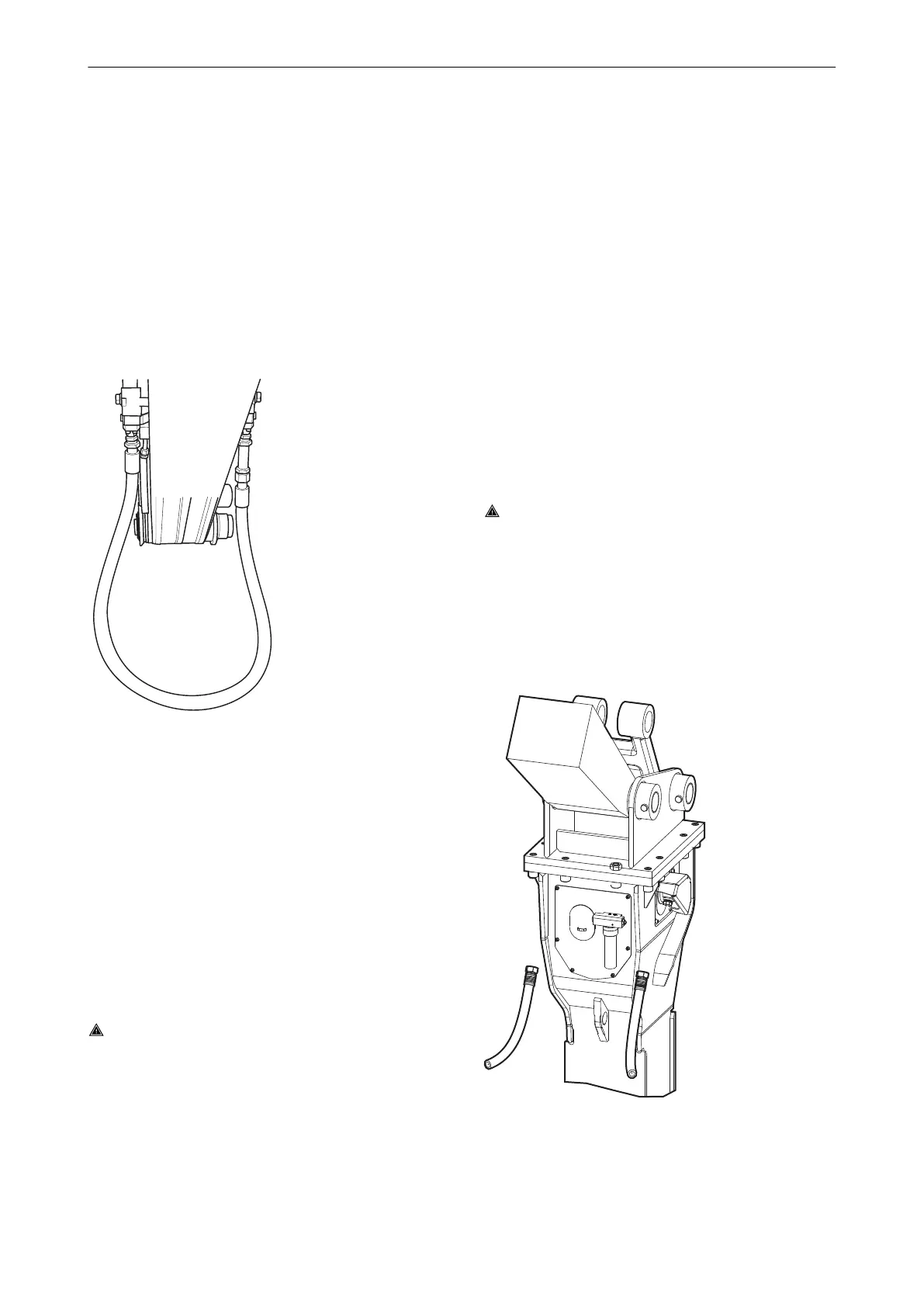

WARNING Components bursting

Components of the swivel joint may burst. Metal

parts may become projectiles and cause serious

injuries and damage property.

►

Always check the swivel joint covers are fitted

properly when attaching the hydraulic breaker

to the carrier.

►

Tighten loosen screw connections (see chapter

Bolt connections / Tightening torques).

►

Immediately replace a defective swivel joint

cover.

◆

Remove the caps from the

ports »P« and »T« and save them for future

use.

The pressure port »P« has been marked with

red paint as an extra reference.

◆

Check that the ports and connections on the

hydraulic breaker and/or on the hydraulic hoses

are not damaged.

◆

Replace any damaged connections.

◆

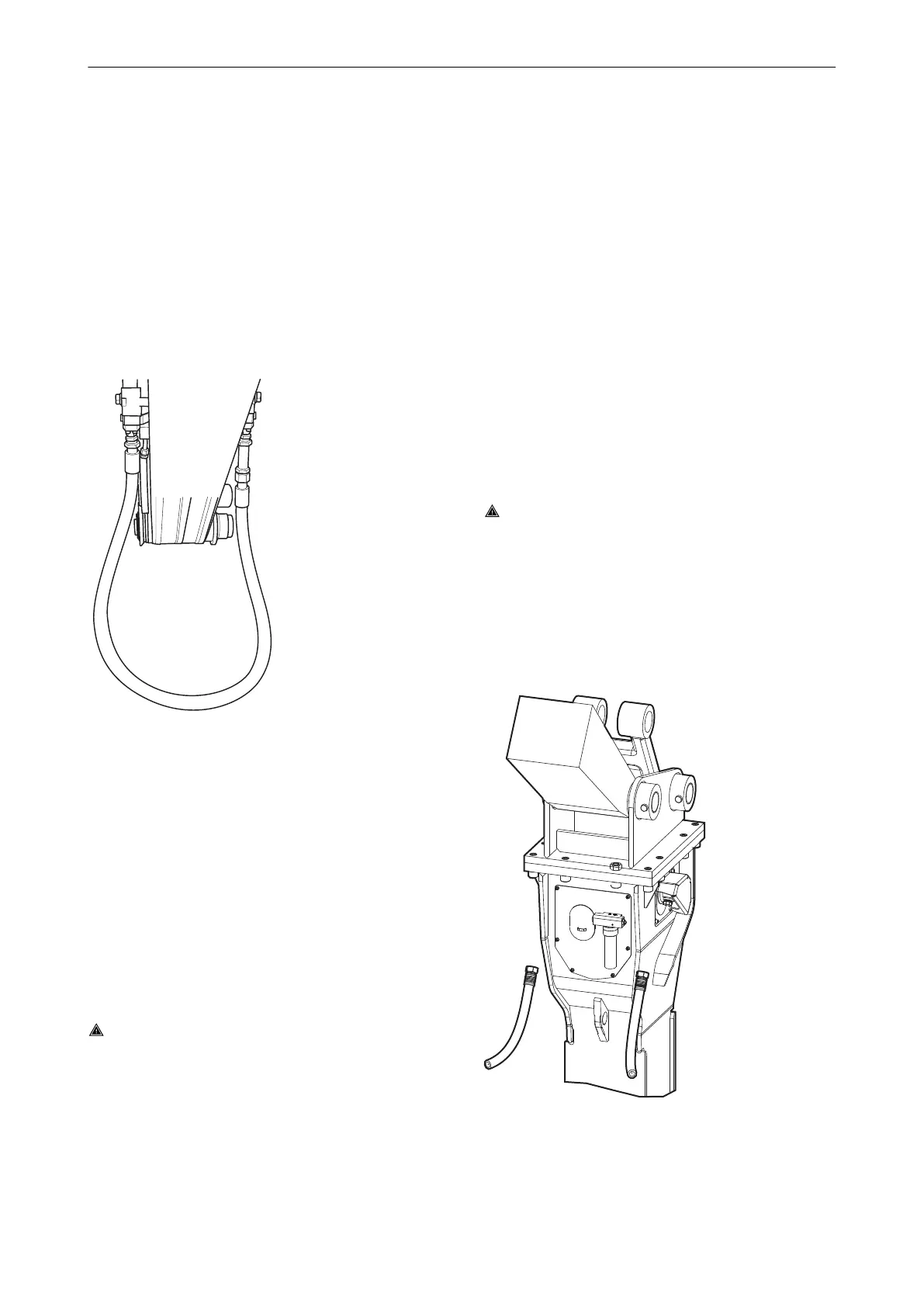

Connect the pressure hose to port »P«, making

sure it is torsion-free.

◆

Connect the tank hose to port »T«, making sure

it is torsion-free.

WARNING Hydraulic hose flailing about

Pressurised hydraulic hoses will flail about when

bolted connections have come loose or have been

loosened. A hydraulic hose flailing about may

cause serious injuries.

►

Tighten the hydraulic hose connection nuts with

the required tightening torque.

Tightening torque (see chapter Bolt connections /

Tightening torques)

HB 2000, 2000 DP, 2500, 2500 DP Safety and operating instructions

© Construction Tools GmbH | 3390 5090 01 | 2016-05-23

Original instructions

25

Loading...

Loading...