Attaching the hydraulic

attachment to the carrier

Mechanical mounting aspects

You need an assistant to attach the hydraulic

attachment to the carrier.

◆

Agree on hand signals with your assistant, to

enable him to help you placing the carrier in the

proper position to attach the hydraulic

attachment.

◆

Lower the stick of the carrier into the holder

provided on the adapter plate.

WARNING Injury by impacts

A sudden movement of the carrier may cause your

assistant to be hit and injured by the boom or the

hydraulic attachment.

►

Only move the boom very slowly and in a

controlled manner while an assistant is within

the danger zone.

►

Always keep sight of your assistant.

WARNING Hands and fingers being cut off

or hurt

Bores and surfaces can act like a pair of scissors

and cut off or hurt parts of your body.

►

Never use your fingers to check bores or fitting

surfaces.

◆

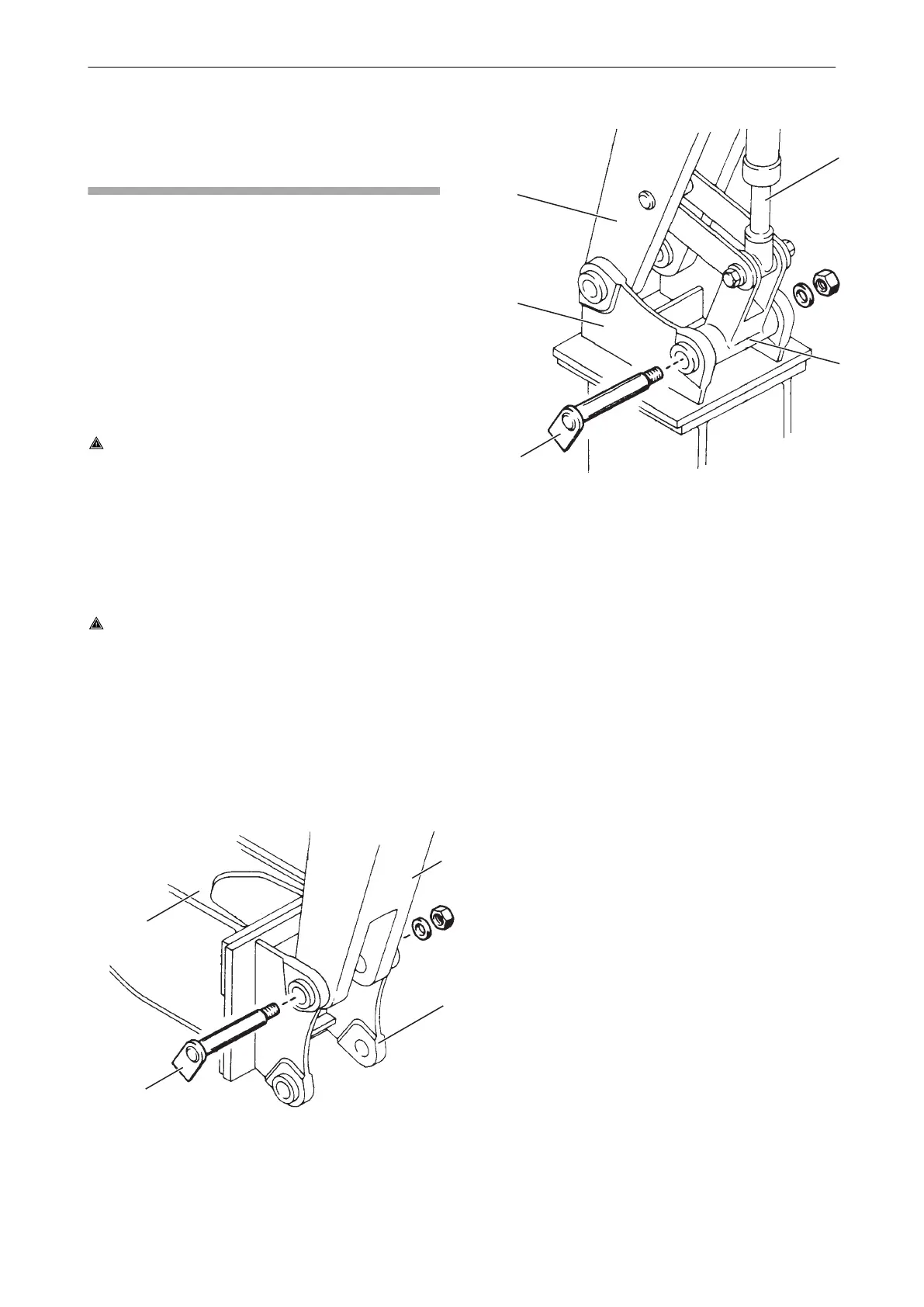

Let your assistant instruct you until the bores in

the adapter plate (B) and in the stick (A) are

properly aligned.

◆

Install the stick bolt (C) and lock it.

◆

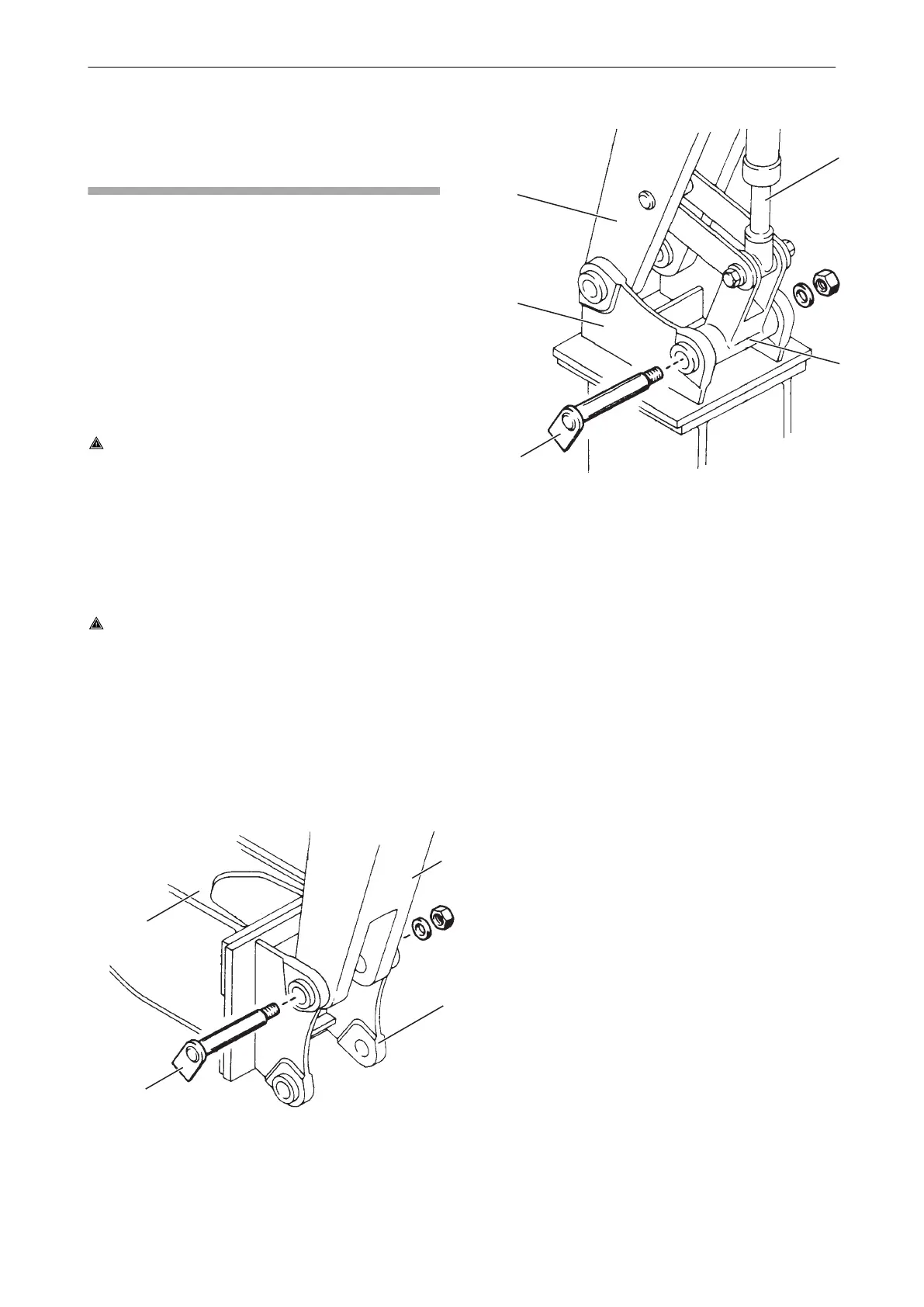

Lift the hydraulic attachment (D).

◆

Extend the bucket cylinder (E) until the bore in

the linkage (F) links up with the bore in the

adapter plate (B).

◆

Install the linkage bolt (G) and lock it.

◆

Carefully move the bucket cylinder (E) into both

end positions.

The adapter plate must not be stopped by

mechanical stops in either position. Consult the

Atlas Copco Customer Center/Dealer in your area

if the adapter plate is stopped by a mechanical

stop.

Making the hydraulic connections

NOTICE Faulty hydraulic installation

The carrier must have a suitable hydraulic

installation to operate the hydraulic attachment.

Improperly installed lines and incorrect rated sizes

may cause the oil to heat up and the hydraulic

attachment to be damaged.

►

Only use hydraulic lines of the rated sizes as

instructed (see chapter Technical

Specifications).

►

Check the rated size of the hydraulic lines on

existing hydraulic installations! Pressure and

tank lines for the hydraulic oil must have a

sufficient inside diameter and wall thickness.

►

Lay all hydraulic hoses so that they are torsion-

free.

◆

Switch off the carrier.

◆

Depressurise the hydraulic system according to

the manufacturer's safety and operating

instructions for the carrier.

◆

If no quick couplings are used, close all shut-off

valves in the installation at the boom.

Safety and operating instructions HB 2000, 2000 DP, 2500, 2500 DP

24 © Construction Tools GmbH | 3390 5090 01 | 2016-05-23

Original instructions

Loading...

Loading...