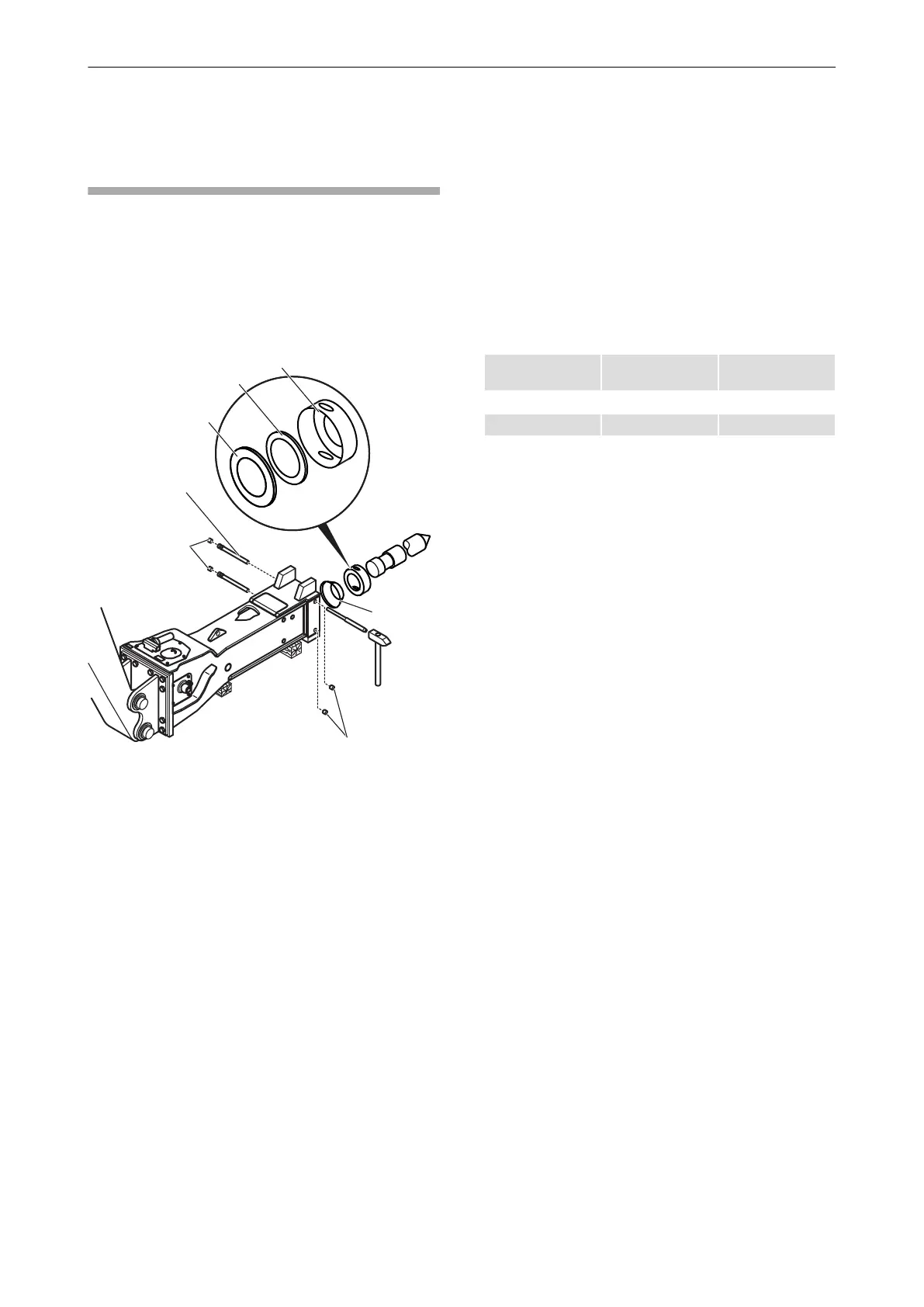

Checking and cleaning the

DustProtector system

An important factor for the DustProtector operation

is that the floating ring which moves in a radial

direction can follow the movements of the breaker

and the working tool.

If dust penetrates it, it may block up the available

installation space and interfere with the

DustProtector system operation.

◆

Regularly check that the floating ring (E) can

move freely.

NOTICE Environmental damage due to chisel

paste

Chisel paste is environmentally harmful and must

not penetrate the ground or enter the water table

or water supplies.

►

Dispose of chisel paste polluted by dust and of

cloths with chisel paste in accordance with the

applicable regulations to avoid environmental

hazards.

Regular cleaning and greasing of the installed

parts and their holders safeguards their operation

and improves the availability of the hydraulic

breaker.

The inspection frequency depends on how much

dust is generated:

Normal dust generation:

once a week (assuming 40–50 hours of operation).

◆

Check more frequently if the floating ring (E) is

stuck.

◆

Remove the floating ring (E), counter ring (D)

and guide ring (F) (see chapter DustProtector/

Removal).

◆

Clean the space in front of the flexible wiper (A)

of all loose dust.

◆

Check the wiper (A) for damage.

◆

Replace the wiper (A) if it is damaged.

◆

Check the inside diameter of the floating

ring (E) with a suitable test gauge or with a

inside calliper.

Type Size information

on test gauge

D

max

HB 2000 DP Ø 145 150 mm

HB 2500 DP Ø 155 160 mm

The diameter measured must not exceed the

maximum permissible diameter D

max

.

◆

If it has eroded so much that its inside diameter

has become too great, replace the floating

ring (E).

◆

Clean and grease the floating ring (E), counter

ring (D) and guide ring (F) and install them

again (see chapter DustProtector/Installation).

Safety and operating instructions HB 2000, 2000 DP, 2500, 2500 DP

50 © Construction Tools GmbH | 3390 5090 01 | 2016-05-23

Original instructions

Loading...

Loading...