Functional test

Always carry out a functional test before putting

the hydraulic attachment into use to check that all

hydraulic lines and connections are tight and that

the hydraulic attachment works without any

problems.

◆

Prepare the hydraulic attachment so that you

can start using it.

◆

Carry out a couple of test impacts on the

material to be broken.

◆

Check the hydraulic lines and make sure that

the hydraulic attachment works without any

problems.

◆

Immediately switch off the hydraulic attachment

if oil escapes from the hydraulic lines or if other

defects in functioning occur.

◆

Depressurise the hydraulic system (see chapter

Depressurising the hydraulic system).

◆

Only use the hydraulic attachment again after

having repaired all leaks and operating defects.

Correct operation

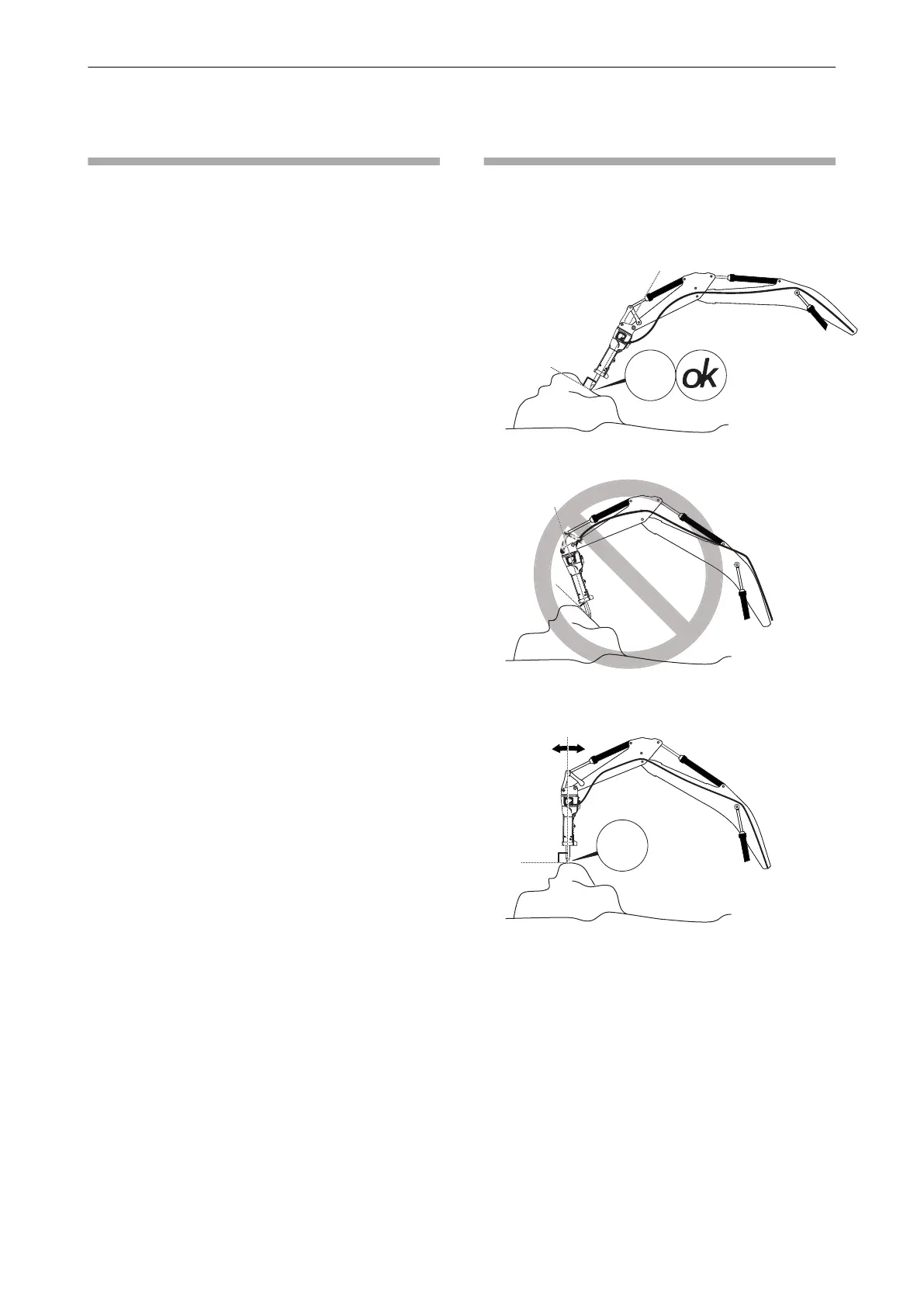

Working angle

◆

Always position the tool so that it hits the

material to be broken at a right angle.

If you do not do this, the hydraulic breaker will

wear faster and damage will occur after a while.

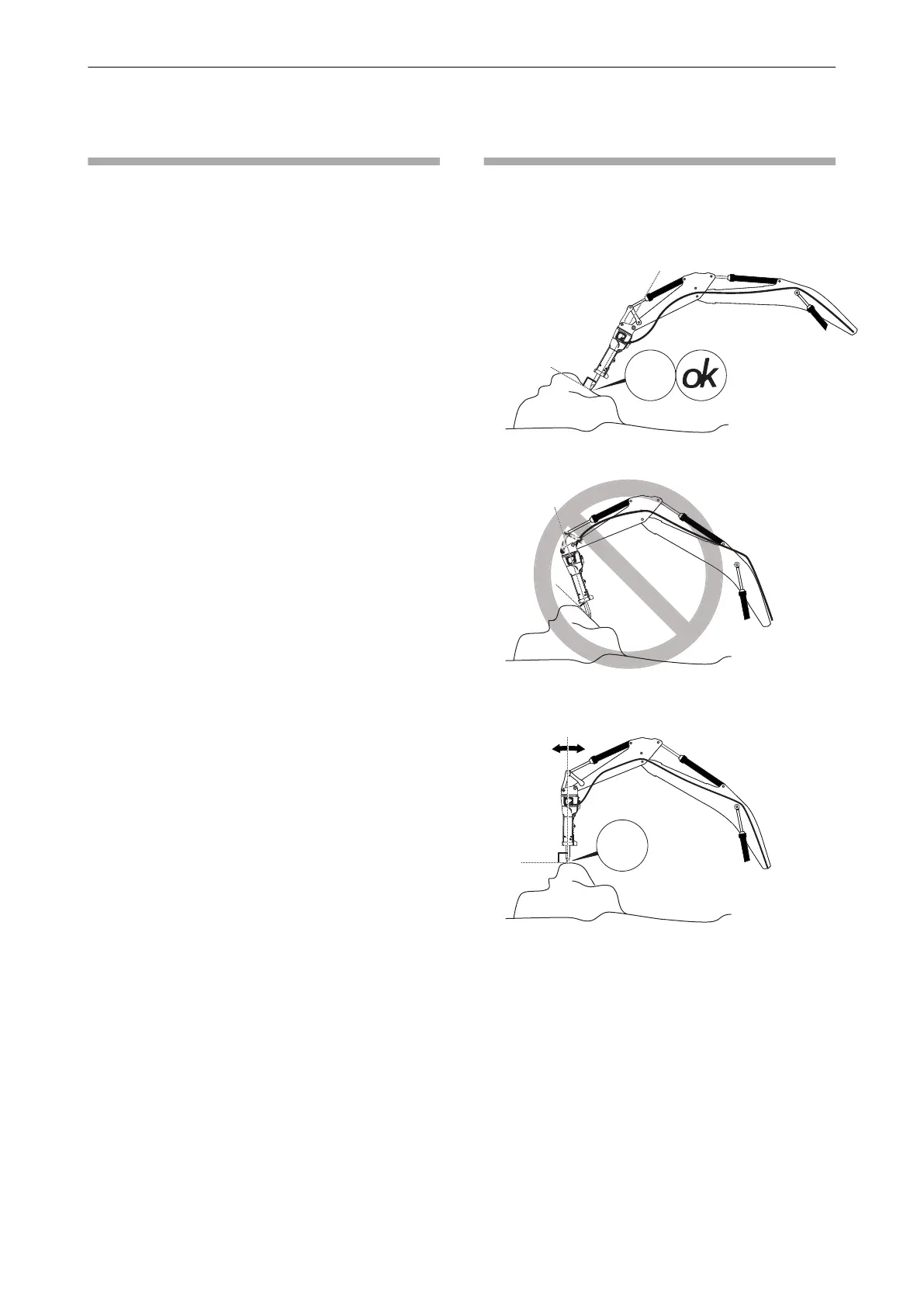

◆

Slightly swing the hydraulic breaker to and fro

when carrying out the hammer impacts, but

never swing it through more than approx. 5°.

This swing action enables any dust under the

tip or the cutter of the working tool to escape.

Otherwise a layer of dust is created which

would prevent the full percussion energy being

transferred to the material to be broken. The tip

of the working tool then becomes hot and loses

its hardness.

Larger swing angles would lead to bending

loads and damage to the working tool and the

hydraulic breaker.

Safety and operating instructions HB 2000, 2000 DP, 2500, 2500 DP

34 © Construction Tools GmbH | 3390 5090 01 | 2016-05-23

Original instructions

Loading...

Loading...