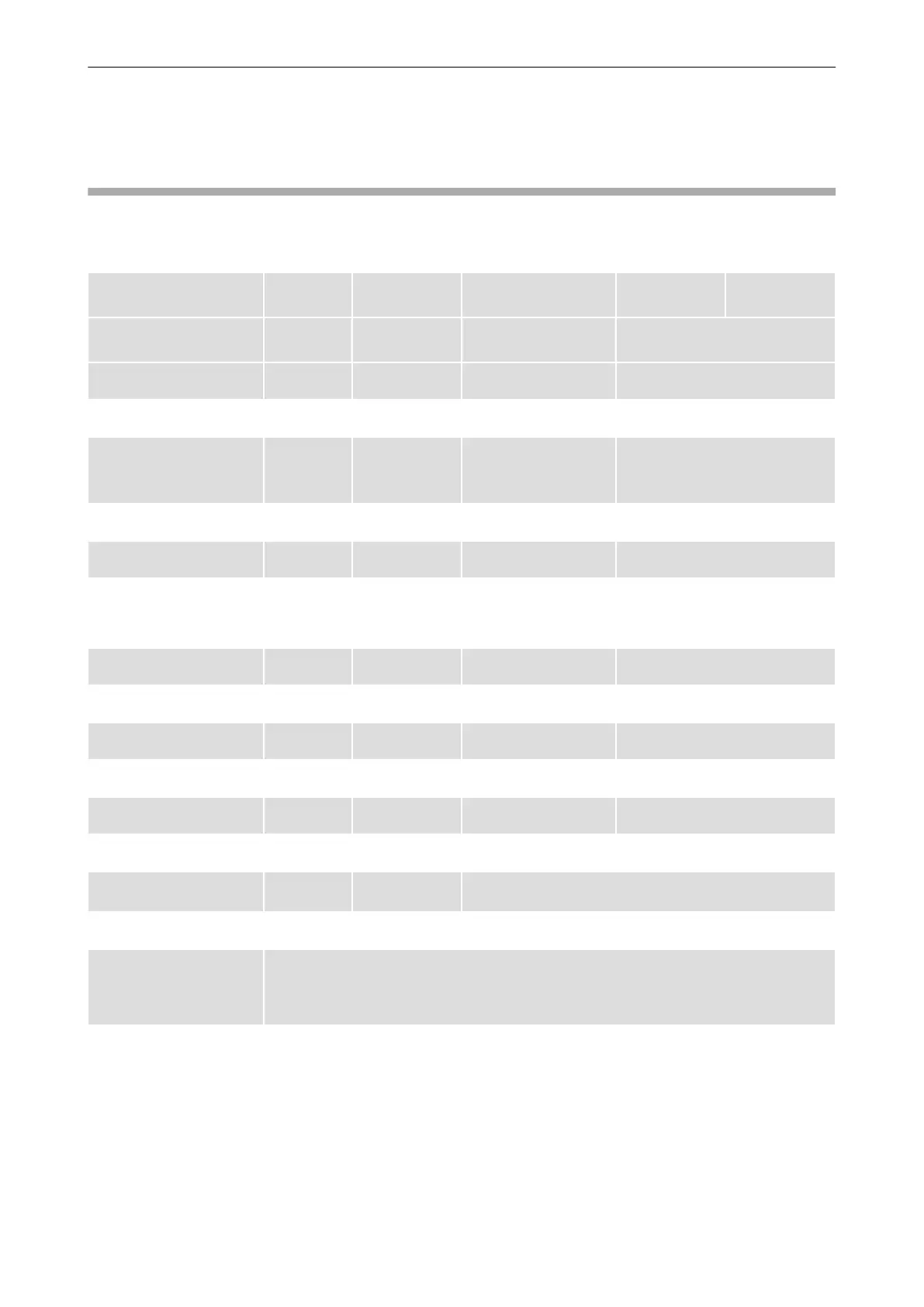

Bolt connections/Tightening torques

The bolt connections of hydraulic breakers are subjected to very high loads.

◆

Tighten any loose connections without exceeding the recommended tightening torques.

HB 2000

HB 2000 DP

HB 2500

HB 2500 DP

Connection point Pos. Interval Type of spanner Size

Torque

Adapter plate*

(fastening screws)

A daily Allen key 22 mm

1500 Nm

Tensioning bolts** B weekly visual

check

Torque spanner/ power

wrench

55 mm 65 mm

Cover for control mechanism /

control mechanism

(Allen screws/hexagon head

screws)

C in case of a repair Allen key 17 mm

380 Nm

AutoControl System D in case of a repair Allen key 22 mm

300 Nm

PowerAdapt E in case of a repair socket spanner 24 mm

300 Nm

Filling valve »G«

(threaded plug)

F in case of a repair socket spanner

Allen key

22 mm

130 Nm

5 mm

20 Nm

Ports »P« and »T« G weekly open-ended wrench 55 mm

285 Nm

StartSelect

(plug)

H in case of a repair Allen key 17 mm

200 Nm

HP-accumulator

(Fastening screws)

I weekly Allen key 14 mm

350 Nm

Flanges

(Allen screws)

J weekly Allen key

10 mm

80 Nm

percussion chamber

ventilation

K in case of a repair open-ended wrench 41 mm

200 Nm

Swivel joint covers

(Allen screws)

L daily Allen key 10 mm

80 Nm

Hose connections

ContiLube

®

II

- weekly Various open-ended spanners with different spanner sizes

* Apply anti-seize compound to the allen screw threads before inserting them. The contact faces of the

screw head and the lock washers must not be lubricated.

**HB 2000

**HB 2500

The tensioning bolt heads can be seen through the openings in the breaker box.

1. Pre-tighten the tensioning bolts to 500 Nm crosswise,

2. retighten 120° (2 hexagons) crosswise,

3. retighten 150° (2.5 hexagons) crosswise

Safety and operating instructions HB 2000, 2000 DP, 2500, 2500 DP

56 © Construction Tools GmbH | 3390 5090 01 | 2016-05-23

Original instructions

Loading...

Loading...