6 Maintenance

6.1 Maintenance warnings

Warnings

Before starting any maintenance or repairs:

•

Stop the compressor. Close the air outlet valve.

•

Press the test buttons on top of the electronic water drains to depressurize the air

system.

•

Press the emergency stop button (S2).

•

Open the isolating switch (customer's installation) to switch off the voltage to the

compressor.

Warranty-Product Liability

Use only Atlas Copco authorized genuine parts. Any damage or malfunction caused by the use of unauthorized

parts is not covered by Warranty or Product Liability.

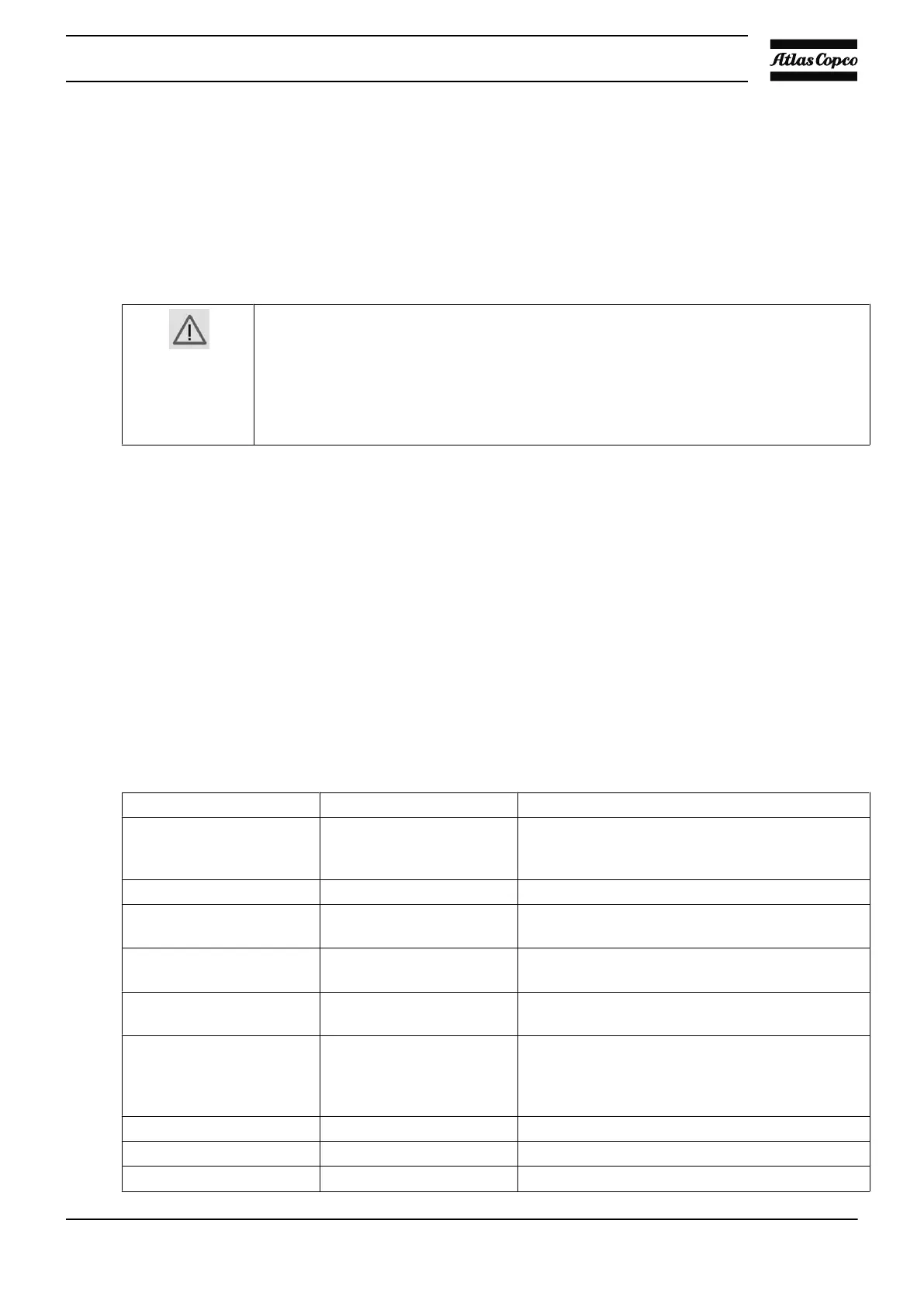

6.2 Preventive maintenance schedule

Regular service operations

To ensure safe operation and long service life, carry out following operations at the interval (period or running

hours) which comes first. The "longer interval" checks must also include the "shorter interval" checks.

The local Atlas Copco Customer Centre may overrule the maintenance schedule depending on the

environmental and working conditions of the compressor.

Period Running hours Operation

-- At initial start Check the pressure differential of the rotor

compartments of the integrated dryer. Adjust if

necessary.

Daily 8 Check readings on display.

Daily 8 Check that condensate is discharged during

loading.

Daily -- Check oil level. Before starting, the level should be

in the middle of the sight-glass.

Weekly 50 Check that the moisture indicator of the integrated

dryer shows blue.

Monthly -- On Full-Feature ND compressors and Full-Feature

compressors with Low load option, check that air is

purged from the low load system. Clean nozzle if

necessary.

3-monthly -- Clean compressor.

3-monthly -- Check for possible leaks.

3-monthly 500 Check coolers, clean if necessary.

Instruction book

115

Loading...

Loading...