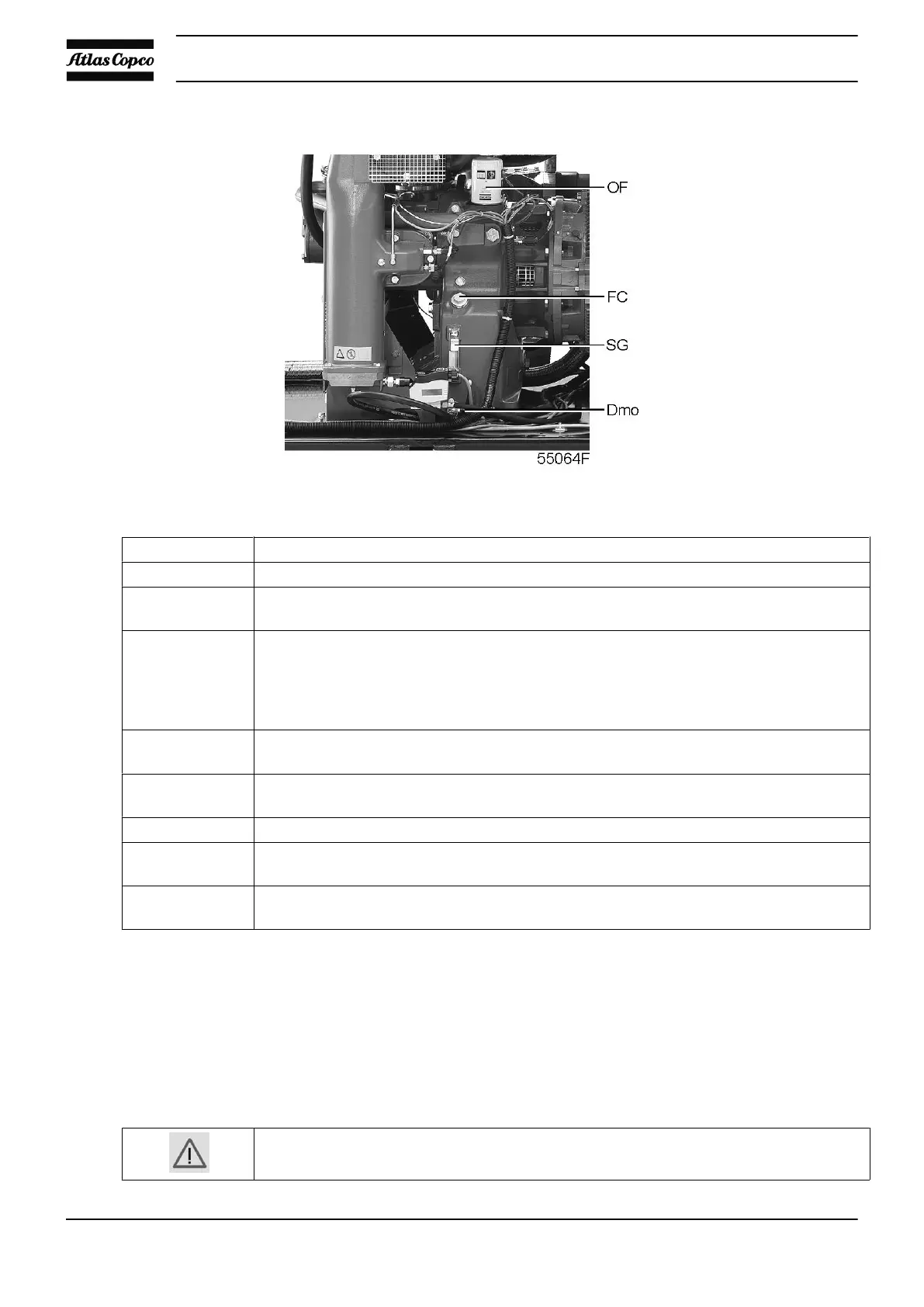

Oil system components, ZT

Procedure

Step Action

1 Run the compressor until warm.

2 Press stop button (1), wait until the compressor has stopped, press emergency stop button

(S2) and switch off the voltage to the compressor.

3 Remove filler plug (FC). Drain the compressor sump by opening drain valve (Dmo). Close

the valve after draining.

Drain the oil cooler by removing its drain plug and vent plug.

Drain the oil of the compressor elements. Yellow-painted drains plugs are provided on

both elements.

4 Remove the oil filter (OF). Clean the filter seat, oil the gasket of the new filter and screw it

into place until the gasket contacts the seat. Then tighten by hand.

5 Fill the compressor sump to the middle of the oil level sight-glass (SG) with oil as specified

in “Oil specifications”. Reinstall the filler plug.

6 Switch on the voltage. Unlock the emergency stop button.

7 Run the compressor for a few minutes. Stop the compressor. If necessary, top up the gear

casing with oil to the middle of the sight-glass (SG).

8 After carrying out the maintenance operations of the related service plan, the service

warning must be reset. See also “Preventive maintenance schedule”.

7.3 Safety valves

Testing

The valves can be tested on a separate compressed air line. If a valve does not open at the pressure specified

in “Settings of safety valves”, consult Atlas Copco.

•

Never run the compressor without safety valves.

•

No adjustments are allowed.

Instruction book

122

Loading...

Loading...