8 Problem solving

8.1 Faults and remedies

Warnings

•

Before starting any maintenance or repairs, stop the compressor, wait until it has

stopped.

•

Close the air outlet valve and press the test button on top of the electronic water drains

to depressurize the air system.

•

Open the isolating switch (customer's installation) to switch off the voltage to the

compressor.

•

Apply all relevant “Safety precautions”.

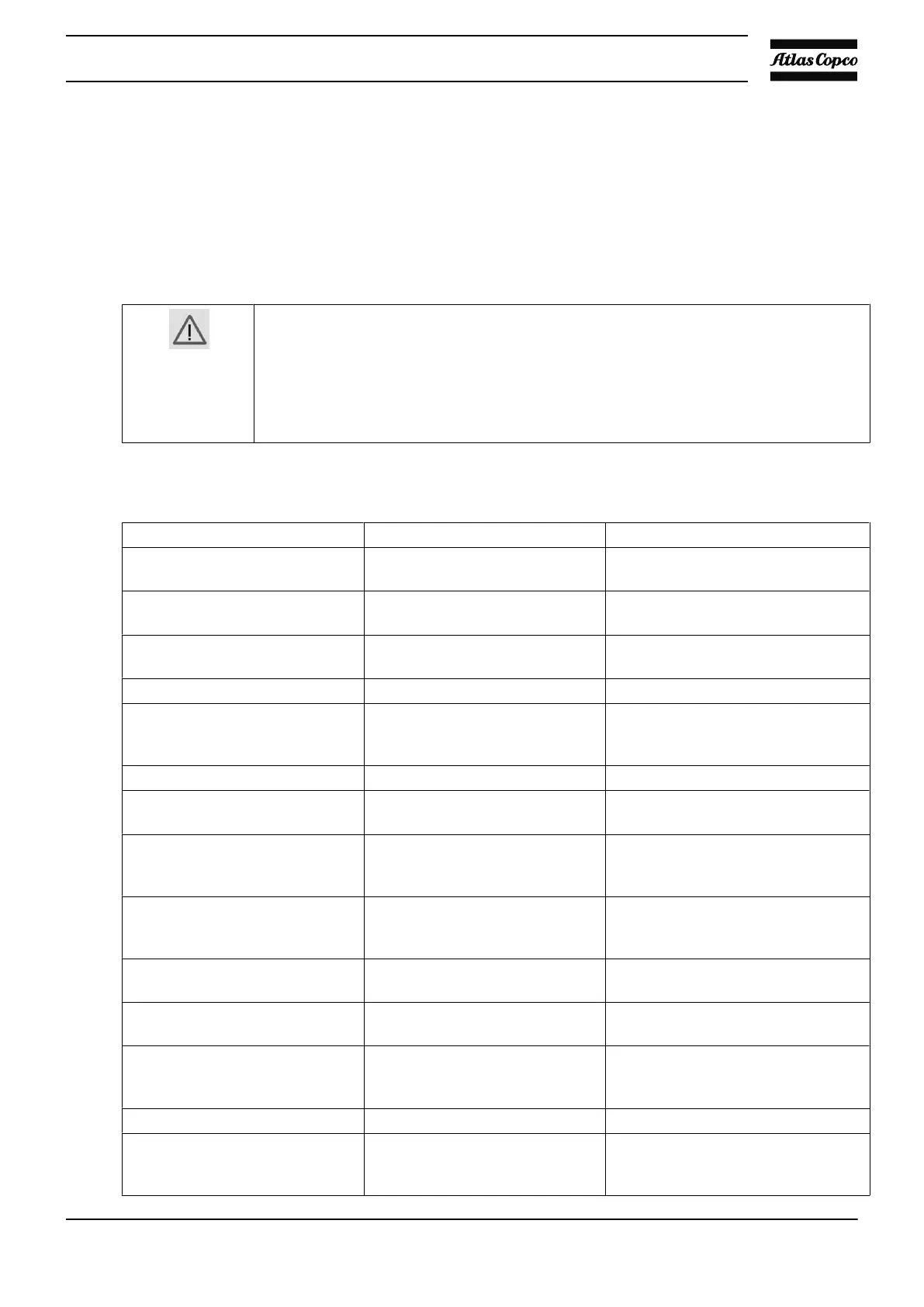

Problem solving, compressor

Condition Fault Remedy

Compressor capacity or working

pressure lower than normal

Air consumption exceeds capacity

of compressor

Check pneumatic plant

Safety valves leaking Remove leaking valve and have it

inspected

Oil pressure too low Oil level too low Top up level to the middle of the oil

level sight-glass

Oil filter clogged Replace filter

Air temperature above normal Inlet temperature too high due to

bad room ventilation or

recirculation of cooling air

Improve ventilation of compressor

room and avoid cooling air

recirculation

Air filter clogged Replace filter

Insufficient cooling water flow Check water temperature and

increase cooling water flow

Restriction in cooling water

system due to formation of scale

or settling down of dirt

Consult Atlas Copco

Condensate is not discharged

from condensate traps during

operation

Discharge flexible clogged Check and correct as necessary

Electronic water drain

malfunctioning

Consult Atlas Copco

LED's of electronic water drain do

not light up

Compressor is running unloaded LED's will light up when the

compressor is loaded again.

Power supply to EWD's faulty Check power supply. Compare power

supply with voltage mentioned on

data label of EWD

Power supply board defective Check and replace as necessary

No condensate discharged when

pressing test button on EWD

System pressure lower than 0.8

bar(e)/11.6 psig

Load the compressor; as soon as the

system pressure exceeds 0.8 bar(e),

condensate will be discharged

Instruction book

123

Loading...

Loading...