Modified cooling water system

The compressor cooling system has been modified to achieve both high cooling water temperatures and

sufficient cooling for the compressor.

The cooling water enters the oil cooler and then flows through the high-pressure compressor element, the

low-pressure compressor element and finally the intercooler and the aftercooler. This sequence ensures

optimal temperature differences with relation to the heat transfer in the individual components.

On Full-Feature compressors, additional connections are provided for the water circuit of the additional

aftercooler and the cooler of the IMD dryer. To ensure that the MD dryer works properly, low-temperature

cooling water should be used for this cooling water circuit. The heat of this cooling water circuit is not

recovered by the energy recovery system.

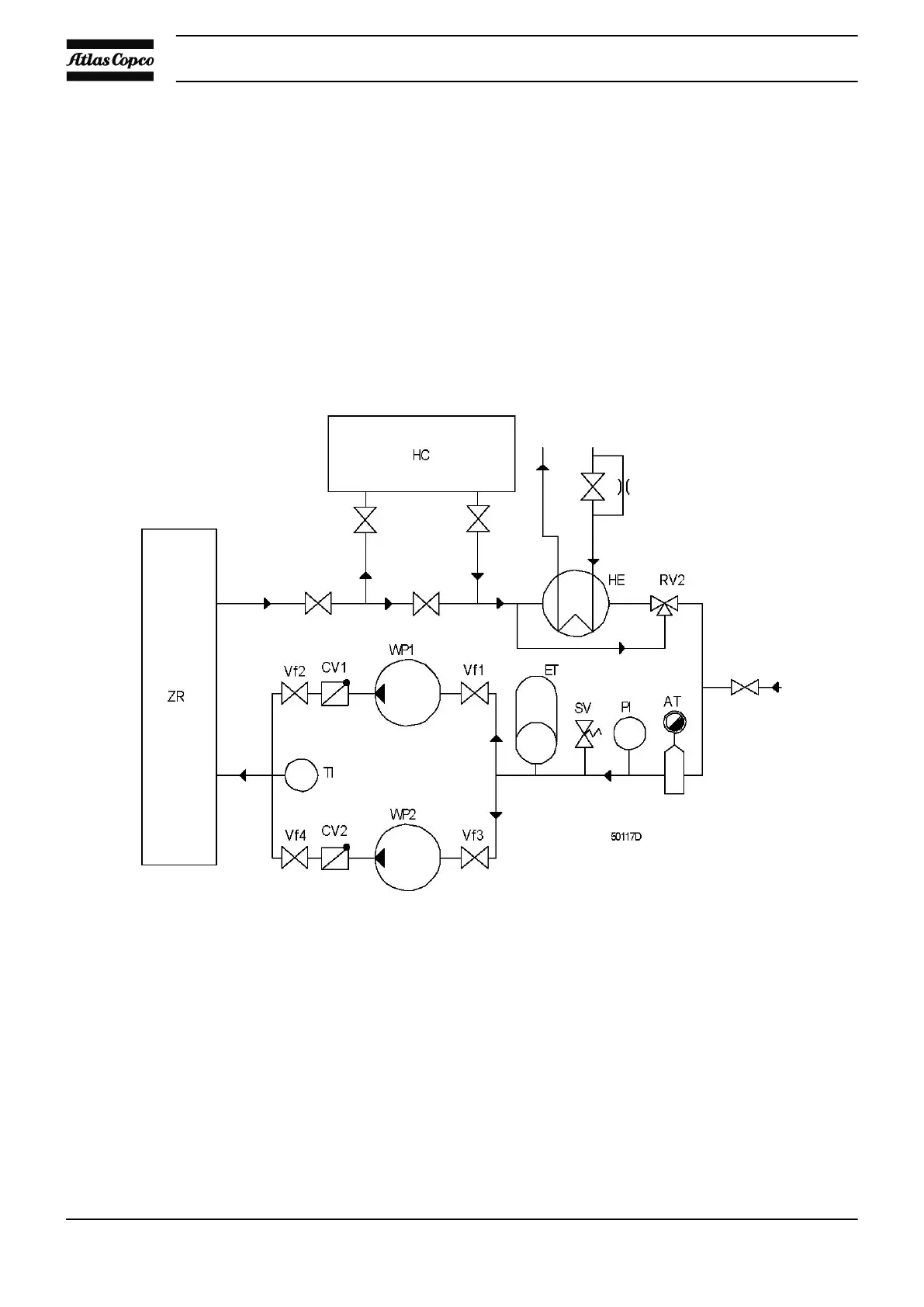

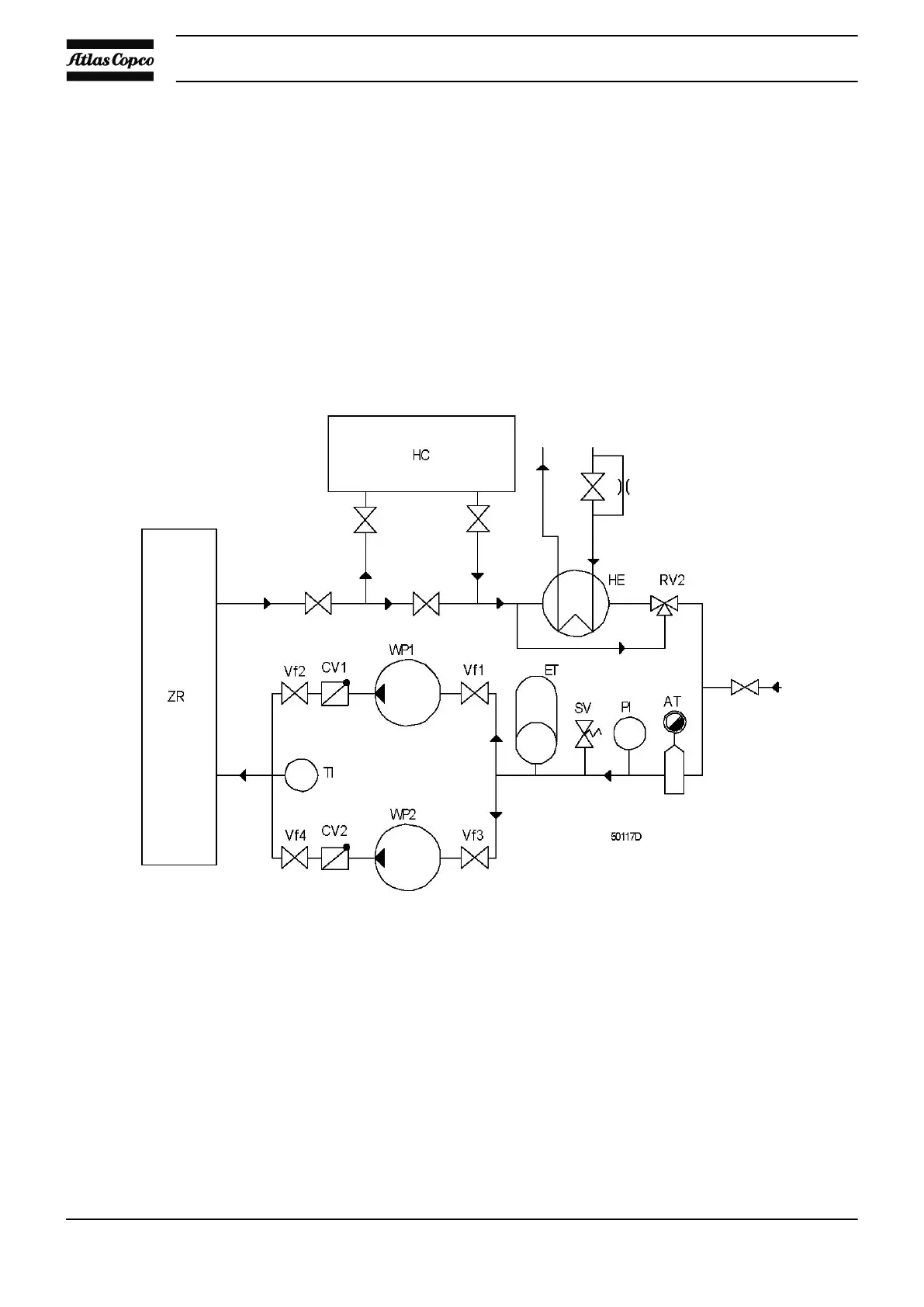

Pump unit

Atlas Copco supplies pump units to transfer the energy recovered from the compressor to the heat consumer

(HC). The pump unit constitutes a closed water circuit with the compressor cooling system.

Two water pumps (WP1/2) are fitted. One pump circulates the hot cooling water from the compressor through

the heat consumer and back to the compressor. The other is a stand-by pump. Check valves (CV1/2) at the

delivery side of the pumps prevent backflow of water in the stand-by pump. The pump unit is fitted with a

make-up water connection, an air trap with automatic de-aeration device (AT), a pressure and temperature

gauge (PI and TI), a safety valve (SV) and an expansion tank (ET).

Cooling water requirements

Closed recirculating water systems minimise make-up water requirements. Therefore, it is economically

feasible to use softened water to eliminate the problem of scaling deposits.

Instruction book

36

Loading...

Loading...