Copyright © WUHAN AU3TECH TRADING CO., LTD

SC1000 Fiber Laser Cutting CNC System User’s Manual Version: V1.00

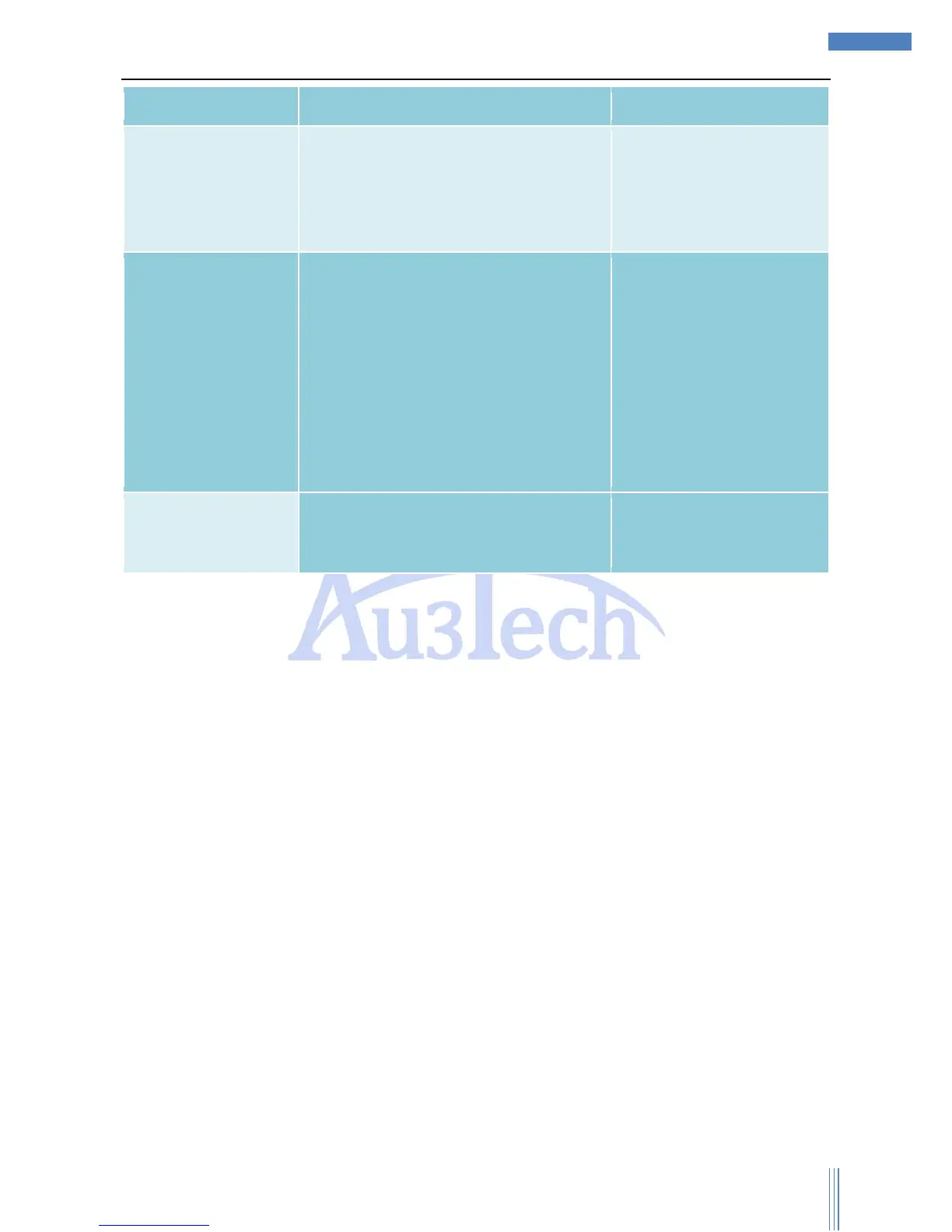

1、Go Origin was set in the wrong direction.

2、X/Y axis’ servo drivers were set in the

wrong direction.

All the directions selected

properly.

The “Home” signal

doesn’t work when Go

Origin.

1、Origin switch broken/the wiring error.

2、Origin’s sampled signal was error.

3、The limited signal wasn’t connected with

the origin signal when making the limited

signal as the original signal.

1 、 Check whether if the

Origin switch and the

indicator light work properly.

2 、 Origin Limit wiring

connected properly.

3 、 Origin sampled signal

selected properly.

SC1000 reminds “X/Y

axis” software limited

alarm

Checked “Enable software limit” before the

cutting head “Go Origin”.

Don’t check “Enable

software limit” before the

cutting head “Go Origin”.

4.2.3 Pulse equivalent setting

Please set up pulse equivalent of each axis properly, or it can be result in running speed error/

accuracy error. The meaning of pulse equivalent: the number of pulse to make the machine run 1mm.

e.g. when X Axis servo motor subdivision is 10000 for running 1 circle, the movement is 10mm, the pulse

equivalent is 10000/10=1000. Pulse equivalent can be set up to 4 digital after decimal point.

4.2.4 Fly-cutting debugging

SC1000 supports all kinds of fly-cutting, please set up all the parameters related properly.

Loading...

Loading...