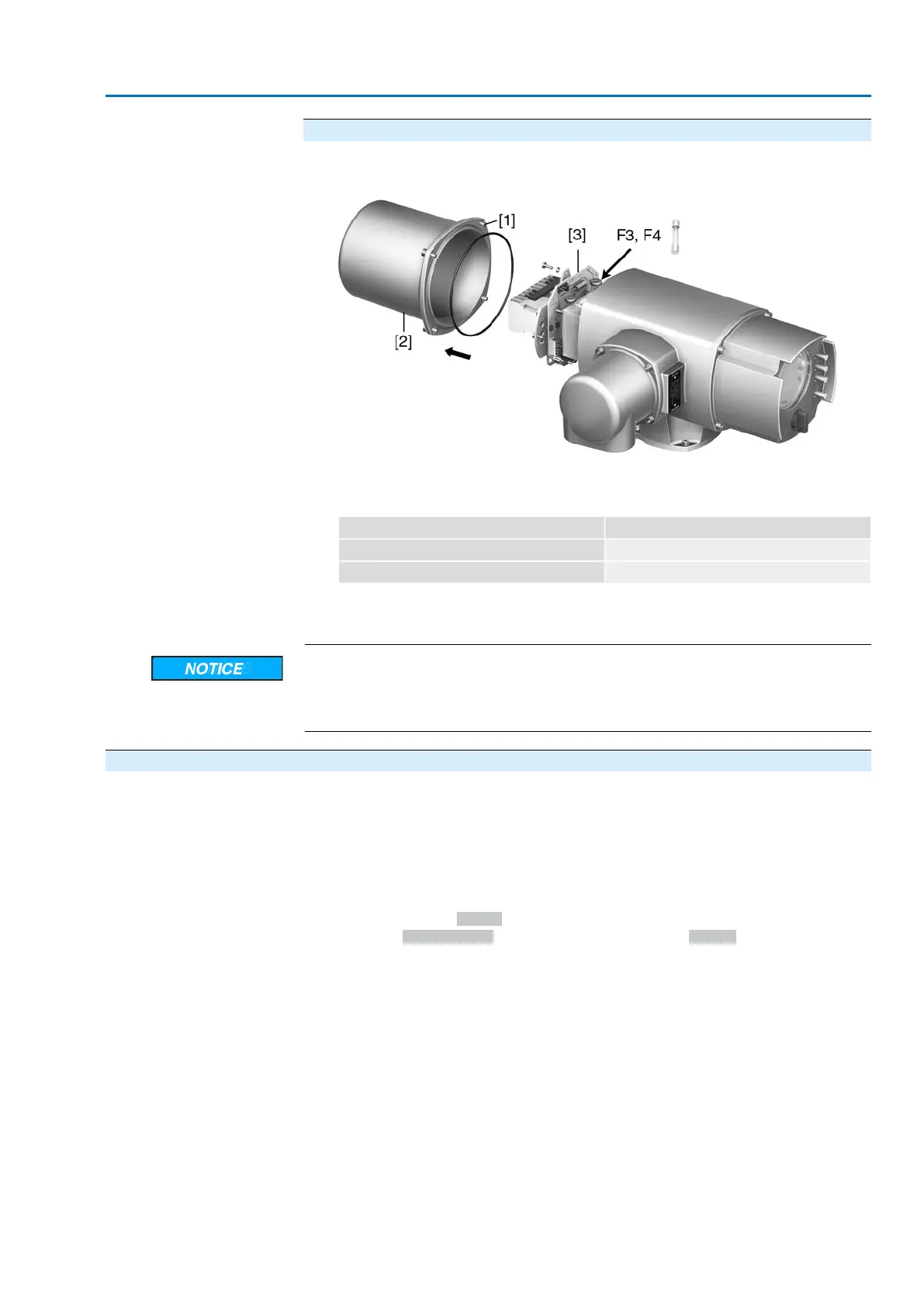

Test/replace fuses F3/F4

1. Loosen screws [1] and remove cover [2] on the rear of the actuator controls.

Figure 76:

The power supply unit has measurement points (solder pins) allowing to perform

a resistance (continuity) measurement:

Table 34:

Measuring pointsChecking

MTP5 – MTP6F3

MTP7 – MTP8F4

2. To replace defective fuses: Carefully loosen power supply unit [3] and pull out.

(The fuses are on the equipped part of the power supply board.)

Cable damage due to pinching!

Risk of functional failures.

→

Carefully assemble power supply unit to avoid pinching the cables.

11.3.2. Motor protection (thermal monitoring)

In order to protect against overheating and impermissibly high surface temperatures

at the actuator, PTC thermistors or thermoswitches are embedded in the motor

winding.The thermoswitch is tripped as soon as the max. permissible winding

temperature has been reached.

The actuator is switched off and the following signals are given:

●

LED 3 (motor protection trippped) on the local controls is illuminated.

●

Status indication S0007 displays a fault.

The fault Thermal fault is displayed when selecting Details.

The motor has to cool down before operation can be resumed.

Depending on the parameter setting (motor protection behaviour), the fault signal is

either automatically reset or the the fault signal has to be reset using RESET push

button with selector switch position Local operation (LOCAL).

For further information to this topic, please refer to Manual (Operation and setting).

73

SA 07.2 – SA 16.2/SAR 07.2 – SAR 16.2 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive HART Corrective action

Loading...

Loading...