4.3.1 Coupling

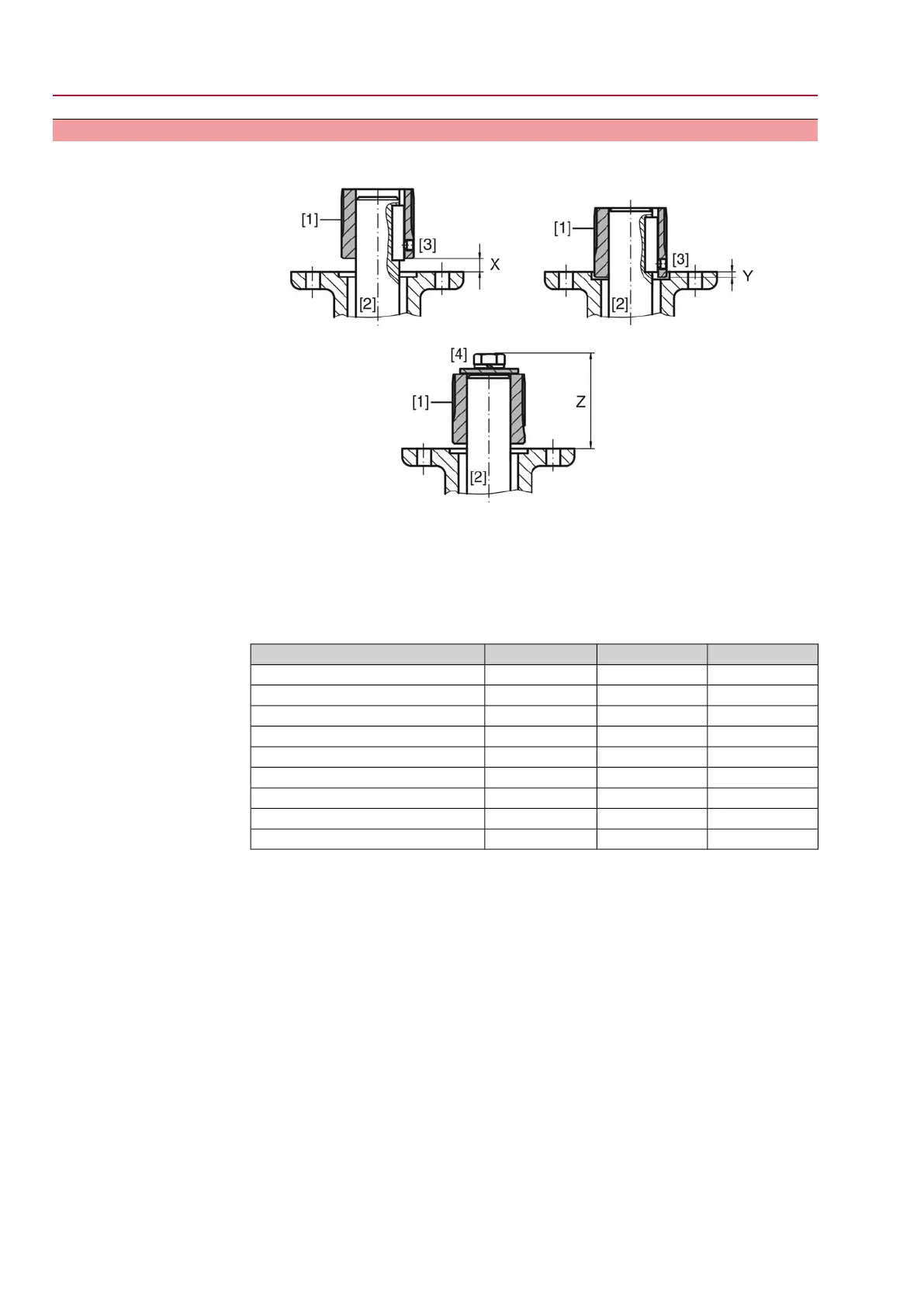

Figure 6: Coupling fitting dimensions

[1] Coupling

[2] Valve shaft

[3] Grub screw

[4] Screw

Table 1: Coupling fitting dimensions

Z max [mm]Y max [mm]X max [mm]Type, size - mounting flange

60–9SG/SGR 05.1-F05

60–9SG/SGR 05.1-F07

60–9SG/SGR 07.1-F07

75–24SG/SGR 07.1-F10

77915SG/SGR 10.1-F10

97–32SG/SGR 10.1-F12

100–25SG/SGR 12.1-F12

120–45SG/SGR 12.1-F14

132–57SG/SGR 12.1-F16

1. Use handwheel to drive actuator to mechanical end stop.

Information: Assemble valve and actuator in the same end position.

- With butterfly valves: recommended mounting position is end position

CLOSED.

- With ball valves: recommended mounting position is end position OPEN.

2. Thoroughly degrease mounting faces of the mounting flange.

3. Apply a small quantity of grease to the valve shaft [2].

4. Place coupling [1] onto valve shaft [2] and secure against axial slipping by using

a grub screw, a circlip or a screw.Thereby, ensure that dimensions X, Y or Z

are observed (refer to figure and table <Coupling fitting dimensions>).

5. Apply non-acidic grease at splines of coupling.

6. Fit actuator.

Information: Ensure that the spigot (if provided) fits uniformly in the recess

and that the flanges are in complete contact.

7. If flange bores do not match thread:

7.1 Slightly rotate handwheel until bores line up.

7.2 If required, shift actuator position by one tooth on the coupling.

12

SG 05.1 – SG 12.1/SGR 05.1 – SGR 12.1 Control unit: electronic (MWG)

Assembly AC 01.1 Non-Intrusive Modbus RTU

Loading...

Loading...