8. Fasten actuator with screws [4].

Information:We recommend glueing the screws using sealing material to avoid

contact corrosion.

→

Fasten screws [4] crosswise with a torque according to table:

Table 2: Tightening torques for screws

Tightening torque T

A

[Nm]Screws

Thread

Strength class 8.8

11M6

25M8

51M10

87M12

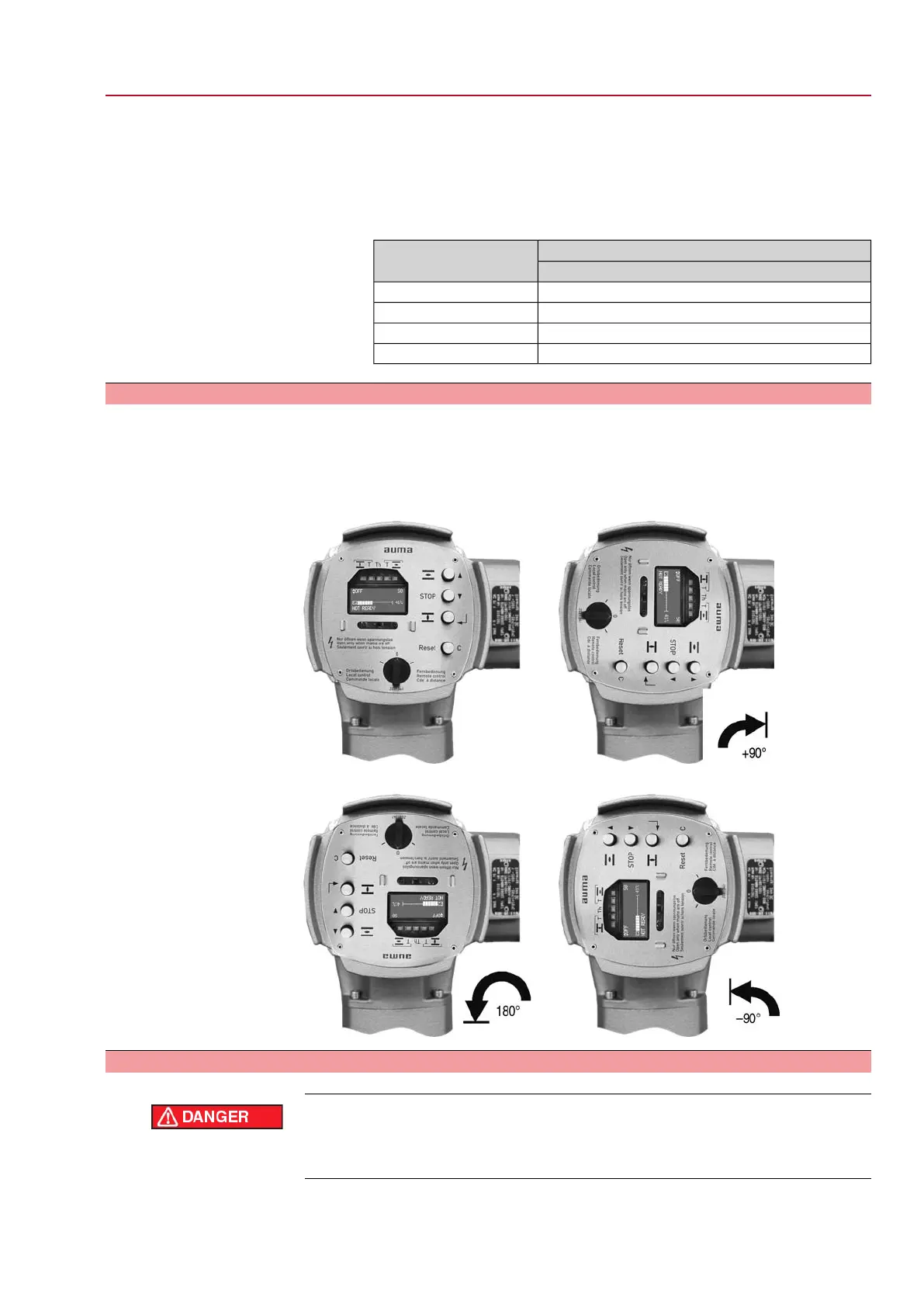

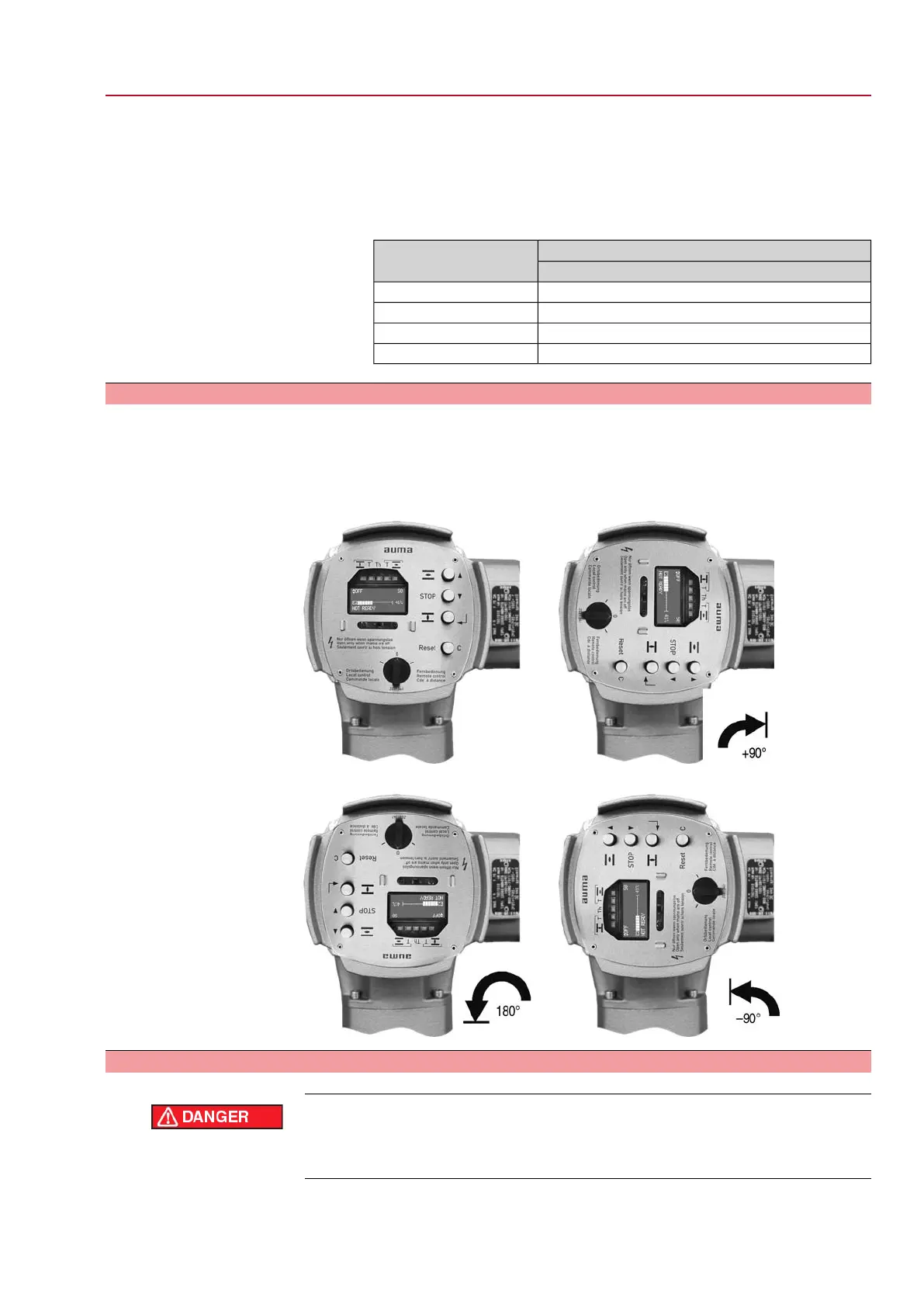

4.4 Mounting positions of local controls

The mounting position of the local controls is selected according to the order. If, after

mounting the actuator to the valve or the gearbox on site, the local controls are in

an unfavourable position, the mounting position can be changed at a later date. Four

mounting positions are possible.

Figure 7: Mounting positions A-2 and B-2

Figure 8: Mounting positions C-2 and D-2

4.4.1 Mounting positions: modify

Hazardous voltage!

Risk of electric shock.

→

Disconnect device from the mains before opening.

1. Loosen screws and remove the local controls.

2. Check whether O-ring is in good condition, correctly insert O-ring.

13

SG 05.1 – SG 12.1/SGR 05.1 – SGR 12.1 Control unit: electronic (MWG)

AC 01.1 Non-Intrusive Modbus RTU Assembly

Loading...

Loading...