6-5

6-3 Cleaning the Flapper

If the flapper is contaminated by instrumentation air, clean it as described below.

Cautions

If air pressure is supplied to the device, the back pressure of the nozzle changes

after the flapper is cleaned, and therefore, the valve opening suddenly changes.

Perform cleaning under conditions where the sudden move of the valve will not

injure people or disturb plant operation.

Step Work

1 Remove the three screws from the pilot relay cover.

2

Prepare a piece of 0.2-mm thick paper. A typical business card

is appropriate.

3

Chip dirt that has accumulated in the space between the nozzle

and flapper in the EPM away with the paper.

4

After cleaning, attach the pilot relay cover to the main unit with

the three screws.

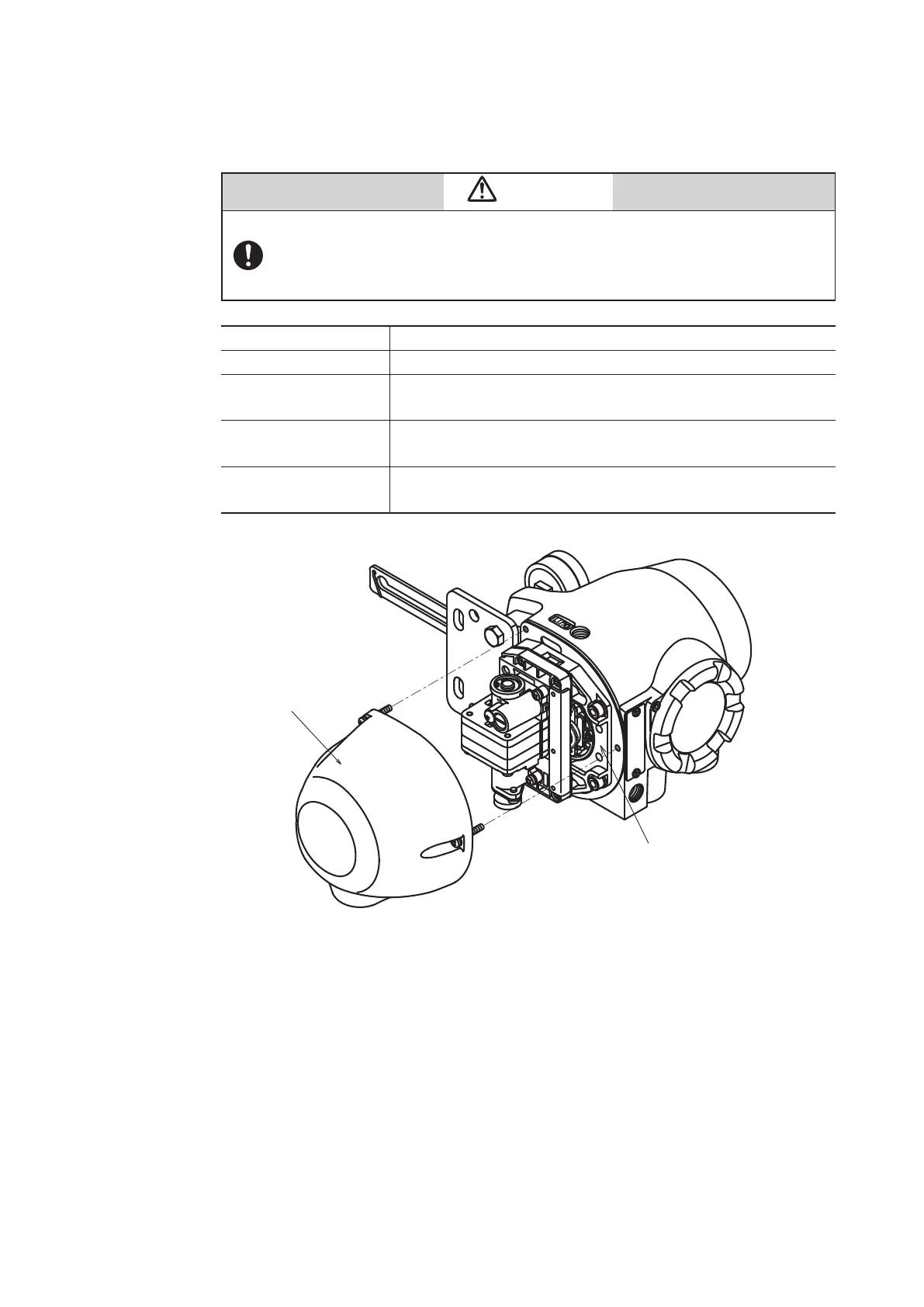

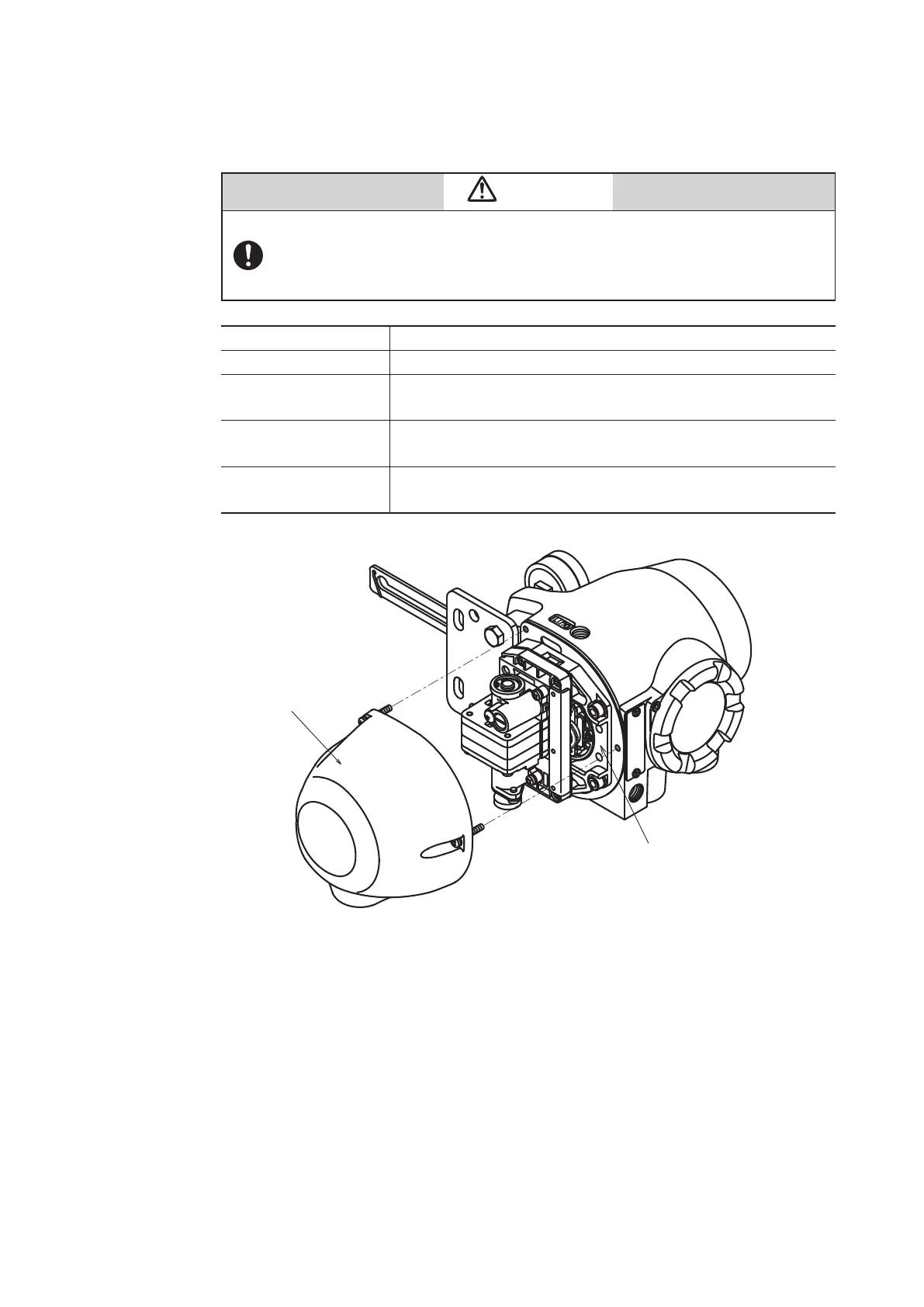

Figure 6-2 Structure

Nozzle flapper

Loading...

Loading...