Receiving & Installation 3-9

MN1276

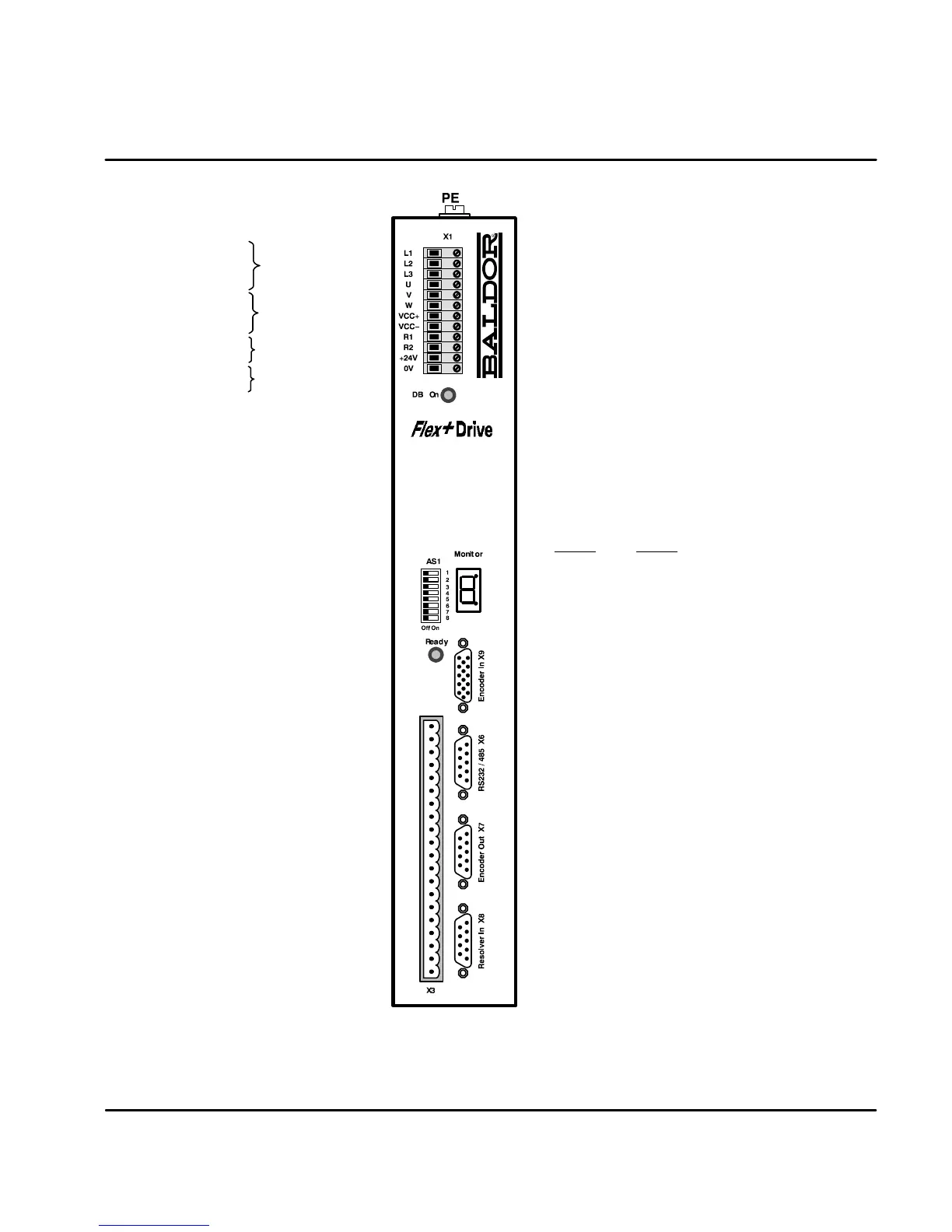

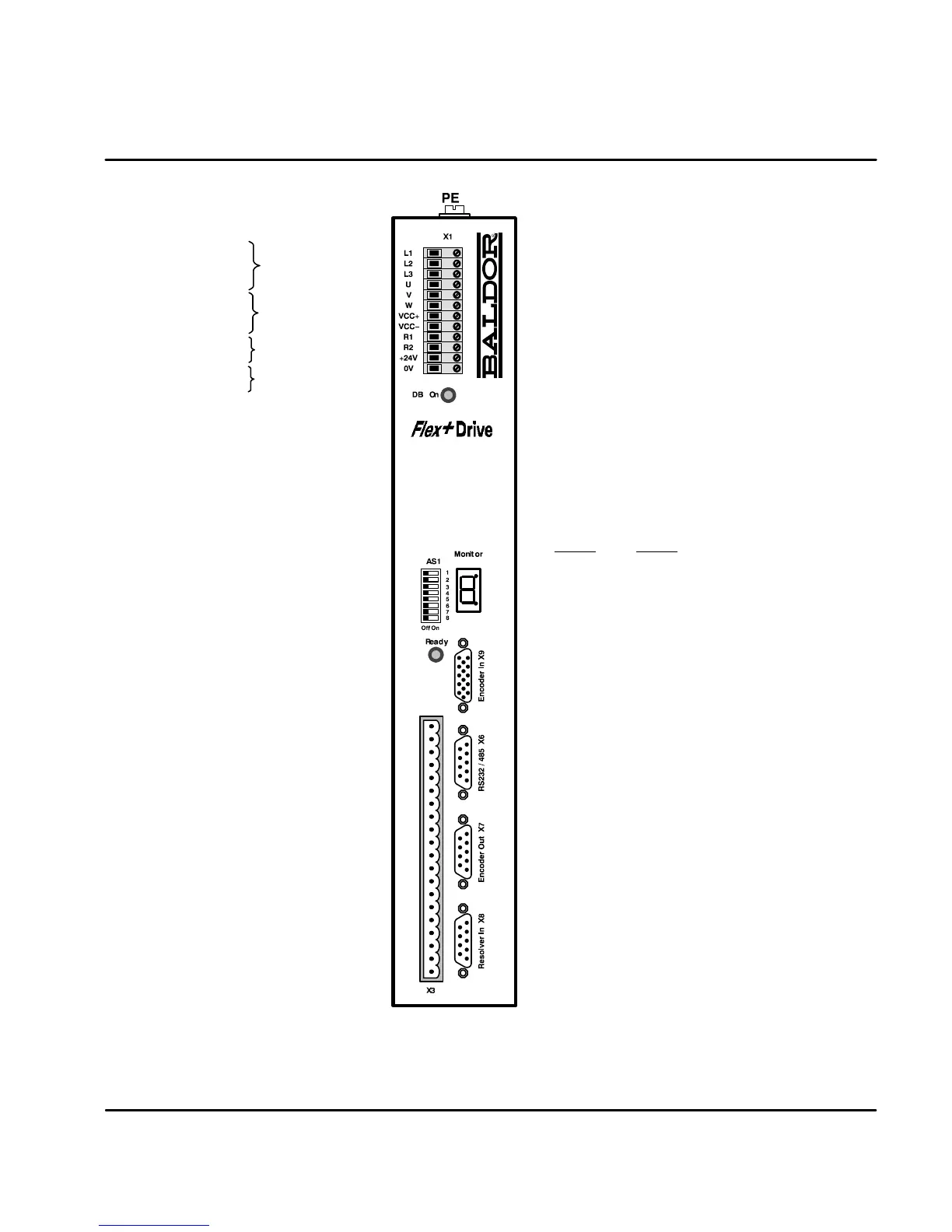

Figure 3-10 Connector Locations (Three Phase Controls)

X6 - RS232 / 485

RS232

RS485

1 Reserved 1 TX-

2R

x

Data 2 TX+

3T

x

Data 3 RX+

4DTR 4RX-

5 DGND 5 DGND

6DSR 6RTS-

7RTS 7RTS+

8 CTS 8 CTS+

9 +5V 9 CTS-

X3 - Control Signals & Digital I/O

1CMD+

2CMD-

3AGND

4 Fault Relay+

5 Fault Relay--

6CIV

7 CREF

8CGND

9 Enable

10 MaI3

11 MaI4

12 Quit

13 Fault Reset

14 Home Flag

15 Trigger

16 MaI1

17 MaI2

18 MaO1

19 MaO2

20 DrOK

X1 - Power Connector

PE Earth

L1 Phase 1 Input

L2 Phase 2 Input

L3 Phase 3 Input

U Motor lead “U”

V Motor lead “V”

W Motor lead “W”

R1 Dynamic Brake

R2 Dynamic Brake

+24V Customer

0V Provided

Dynamic Brake

(Regen Resistor)

Motor

Input Power

X7 - Simulated Encoder Output

1 CHA 6 CHA--

2 CHB 7 CHB--

3 CHC 8 CHC--

4 Reserved 9 Reserved

5DGND

¡ Important:

FPxAxxxx-xxx3 only.

A separate 24VDC supply to the “Logic Power” input is required for

operation. An FPxAxxxx-xxx3 control will not operate without 24VDC on this input.

FPxAxxxx-xxx3

only ¡

X8 - Resolver Input

1 REF 6 REF--

2 COS 7 COS--

3SIN 8SIN--

4 Reserved 9 Reserved

5AGND

Note: Reserved means no connection is required

and no connection should be made to this

terminal. It is reserved for future use.

X9 - Encoder Feedback Option

(only --Exxx versions)

1 CHA+ 9 HALL3+

2 CHB+ 10 HALL2+

3 CHC+ 11 +5VDC

4 HALL1+ 12 N.C.

5 HALL1-- 13 DGND

6 CHA-- 14 HALL3--

7 CHB-- 15 HALL2--

8 CHC--

Terminal tightening torque is

0.5 lb-in (0.6Nm)

The holes in the top and bottom of the

enclosure are for cable clamps. Be sure

to use an M4 bolt 12mm in length.

Longer bolts may short circuit the

electrical components inside the control.

Loading...

Loading...