A-6 Manual Tuning

MN1276

POLE

PLACEMENT

Pole placement provides a “no--overshoot response” when tuned for the correct

inertia. This is the easiest and recommended method of adjustment.

Inertia Click in the “Load” block and enter the value in Kg--cm

2

. The range is from

0to133Kg--cm

2

.

If the inertia is under--estimated, the system will be stable. If the inertia is

over--estimated, the system will vibrate or oscillate due to too much system gain.

If the load inertia is unknown, estimate low. It is recommended to start with “load

inertia = 0.2”, which represents a stable condition.

If you entered the “inertia ratio”, you should enter a value representing the ratio of

reflected load inertia to motor inertia. The range is from 0 to 100.

Response Move to the “Response” block and place the cursor in the “bandwidth” window,

and click on it.

The “bandwidth” is a measure of the range over which the system can respond. It

is expressed in frequency or Hertz. This parameter controls the “rise time” of the

system. It does not effect overshoot.

It is recommended that bandwidth is increased only if higher dynamic response is

required. Increase the bandwidth and observe (go to plotting of move) the

“velocity” and “command current”, until current reaches maximum value, then back

off to 80%. The range is from 10--200.

The next step, would be to verify that the v alue you entered, provides for adequate

system response. You can check this out, by having the software move the

equipment and plot the response. Proceed to “Plotting of Move”.

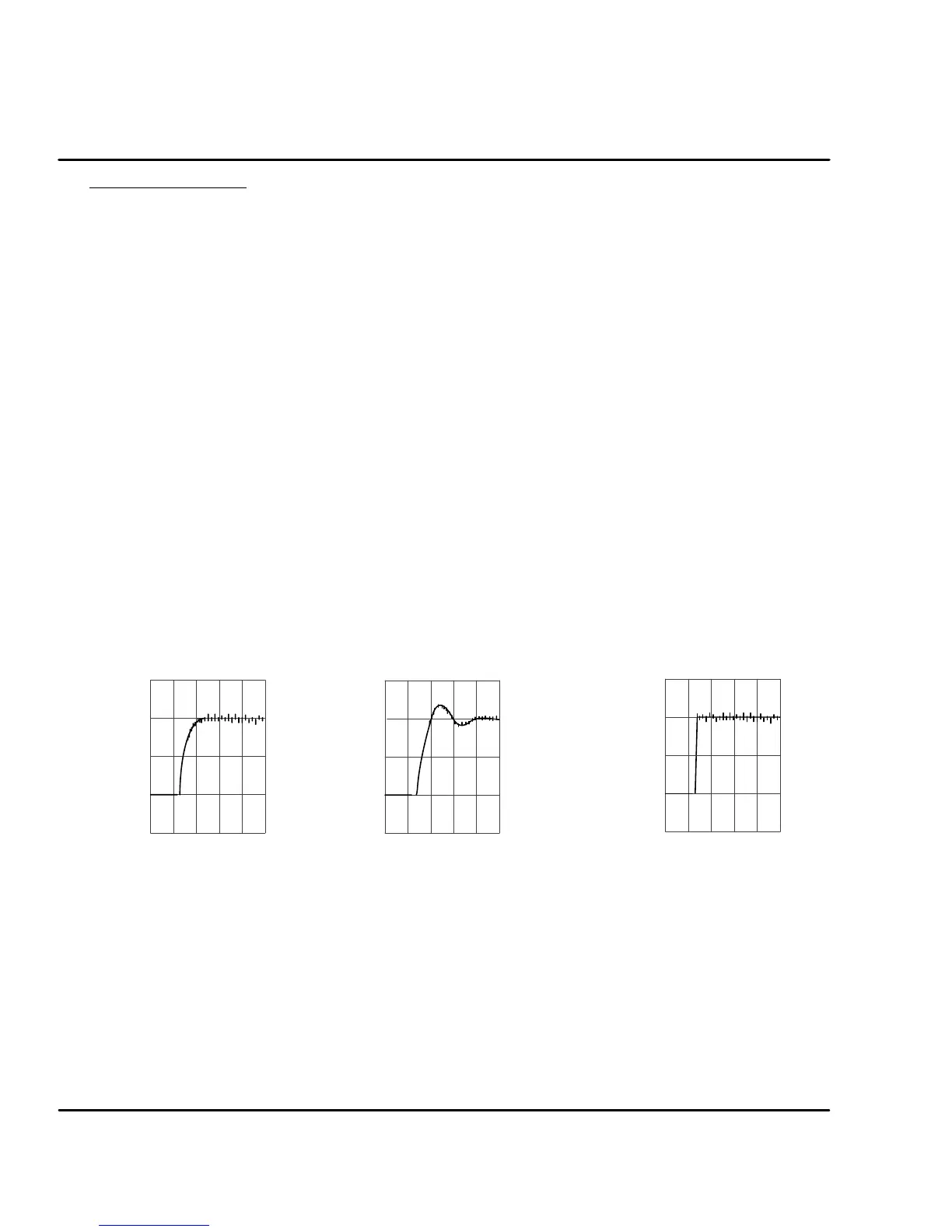

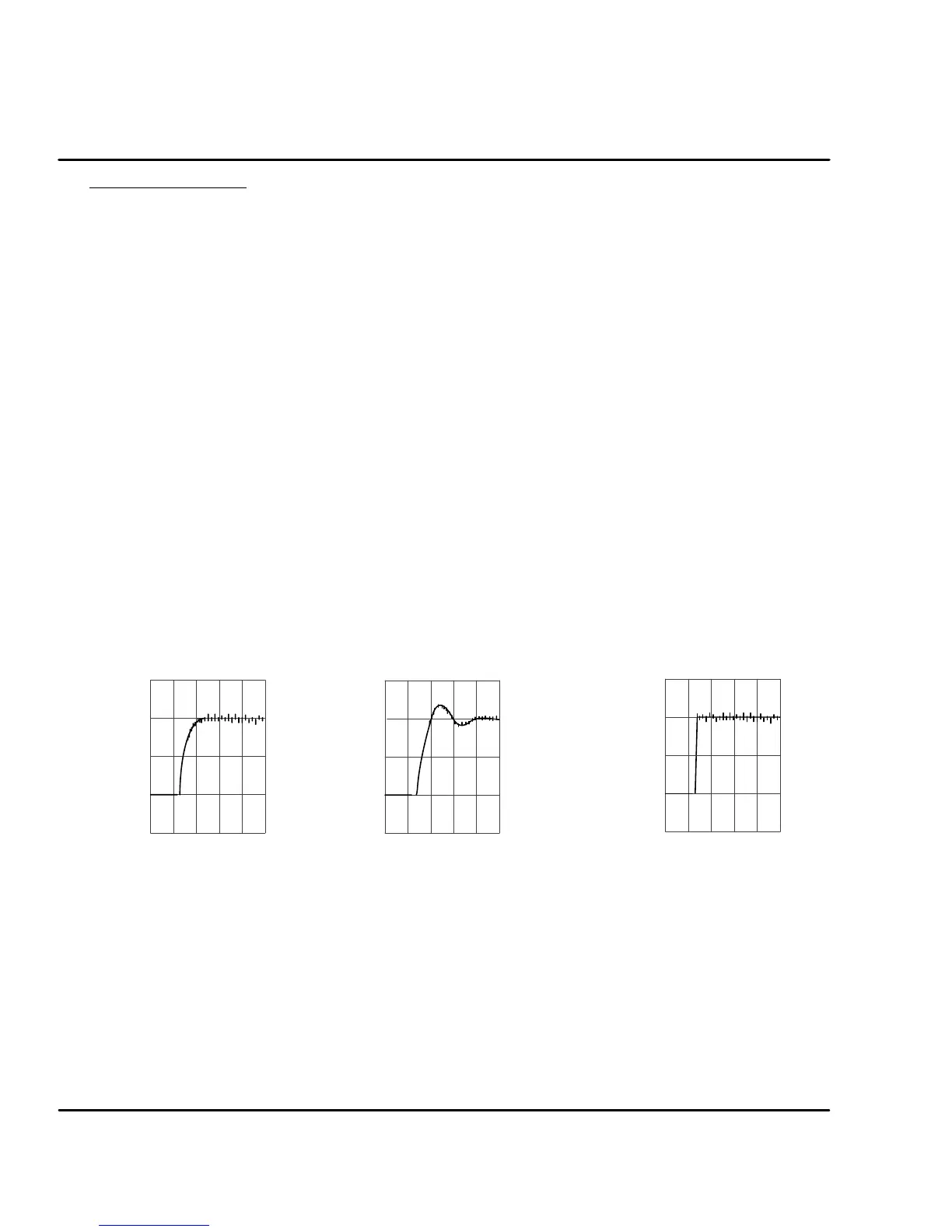

Figure A-10 Inertia and Load Response Examples

Velocity (RPM)

Time

Velocity Command / Velocity

--500

0

500

1000

1500

Velocity (RPM)

Time

Velocity Command / Velocity

-- 5 0 0

0

500

1000

1500

Over--Estimated Under--Estimated

Velocity (RPM)

Time

Velocity Command / Velocity

-- 5 0 0

0

500

1000

1500

Good Response

Tracking factor

The tracking factor parameter controls the amount of tracking versus overshoot.

The range is 0 to 200. A “tracking factor” of “0” generates no overshoot. A

“tracking factor” of 200 results in a PI equivalent control (i.e. with overshoot).

The next step, would be to verify that the v alues you entered, provides for

adequate system response. You can check this out, by having the software move

the equipment and plot the response. Proceed to “Plotting of Move”.

Click in the “Tracking” block and enter the desired adjustment value. This

adjustment is used for applications that require improved tracking (or following)

capability, to improve (or reduce) following error.

Loading...

Loading...