4-2 9424200996

Contact Inputs and Outputs BE1-11m

input(s) that you want to configure. Observe all electrostatic discharge (ESD) precautions when

handling the BE1-11m.

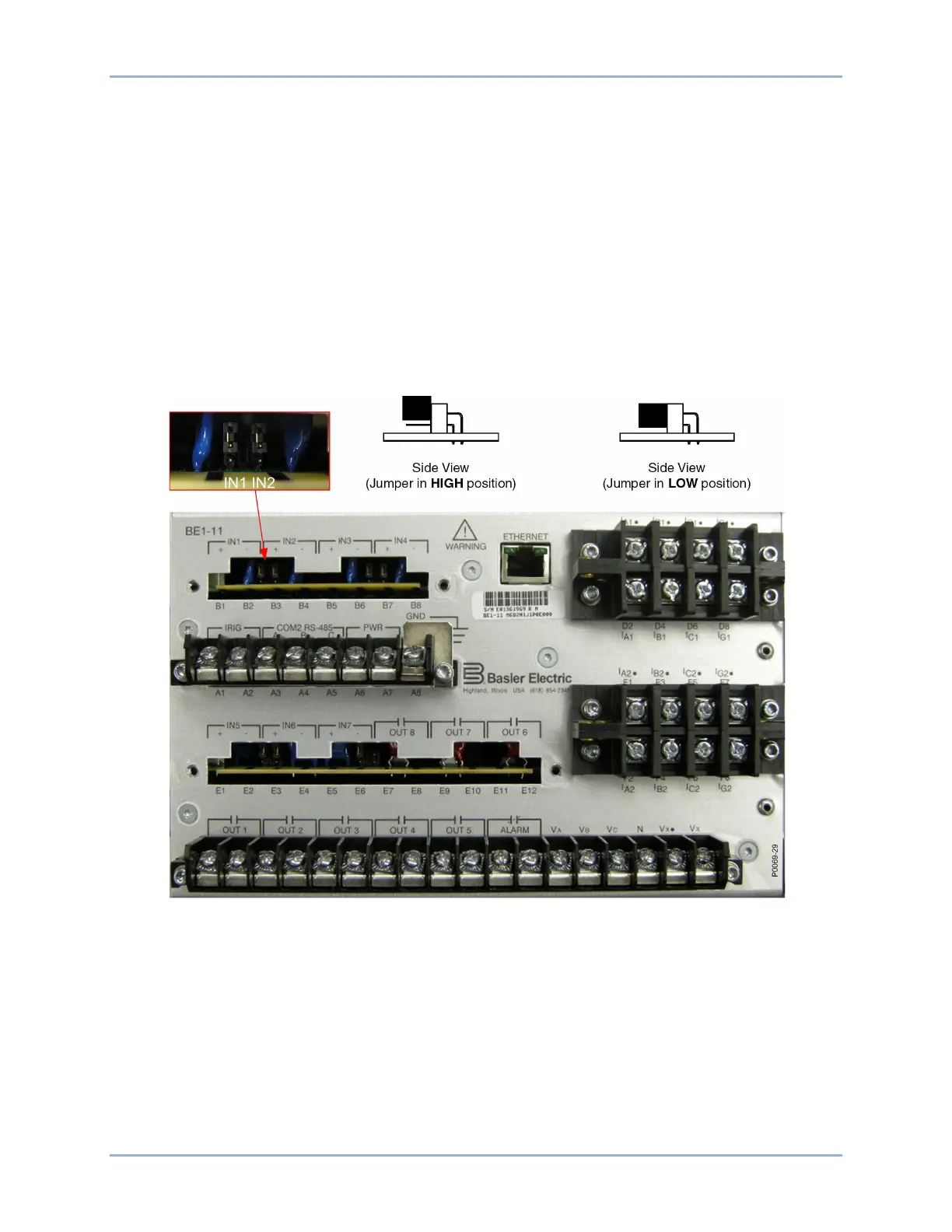

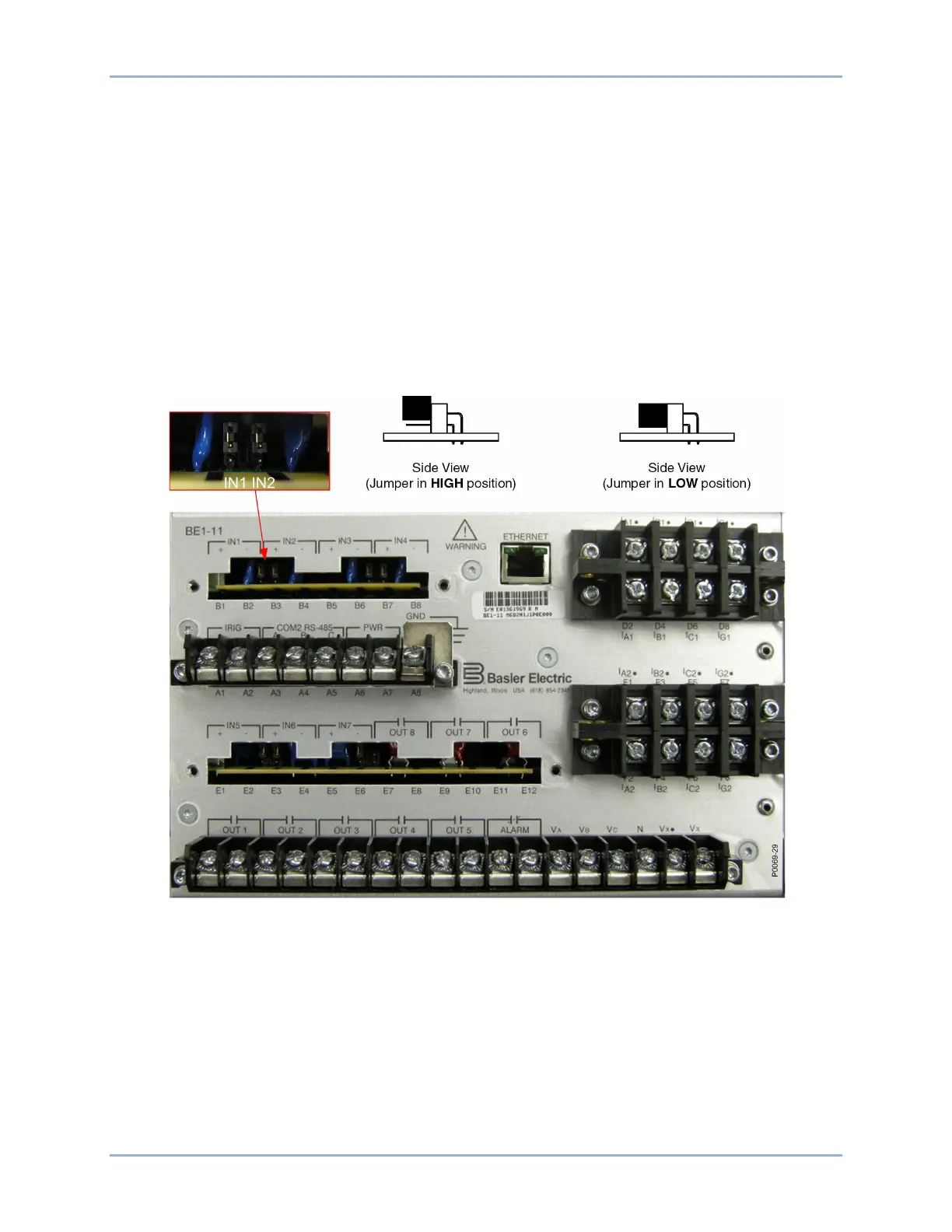

3. Using the input labels on the rear panel as a guide, locate the appropriate jumper terminal block

that is mounted on the circuit board. Each terminal block has two sets of pins. With the jumper as

installed at the factory, one pin should be visible when viewed from the back of the unit. This

configuration allows the inputs to operate at the higher end of the control voltage range. Figure

4-1 illustrates the location of the contact-sensing jumpers. The jumpers are shown in the HIGH

position.

4. To select operation at the lower end of the control voltage range, install the jumper across the two

pins using needle-nose pliers. Use care when removing and installing each jumper so that no

components are damaged.

5. When all jumpers are positioned for operation in the desired control voltage range, reinstall the

rear terminal block(s).

6. Using a 7/64” hex tool, tighten the screws to 10 in-lbs (1.12 N•m).

Figure 4-1. Contact-Sensing Jumper Locations (Standard I/O Option)

Digital Input Conditioning Function

Status of the contact-sensing inputs is checked every 1 millisecond. User-settable digital contact

recognition and debounce timers condition the signals applied to the inputs. These parameters can be

adjusted to obtain the optimum compromise between speed and security for a specific application. (See

Figure 4-2.)

If the sampled status of a monitored contact is detected as energized for the recognition time, the logic

variable changes from a de-energized (logic 0 or false) state to an energized (logic 1 or true) state. Once

contact closure is recognized, the logic variable remains in the energized state until the sampled status of

the monitored contact is detected to be de-energized for a period that is longer than the debounce time.

Loading...

Loading...