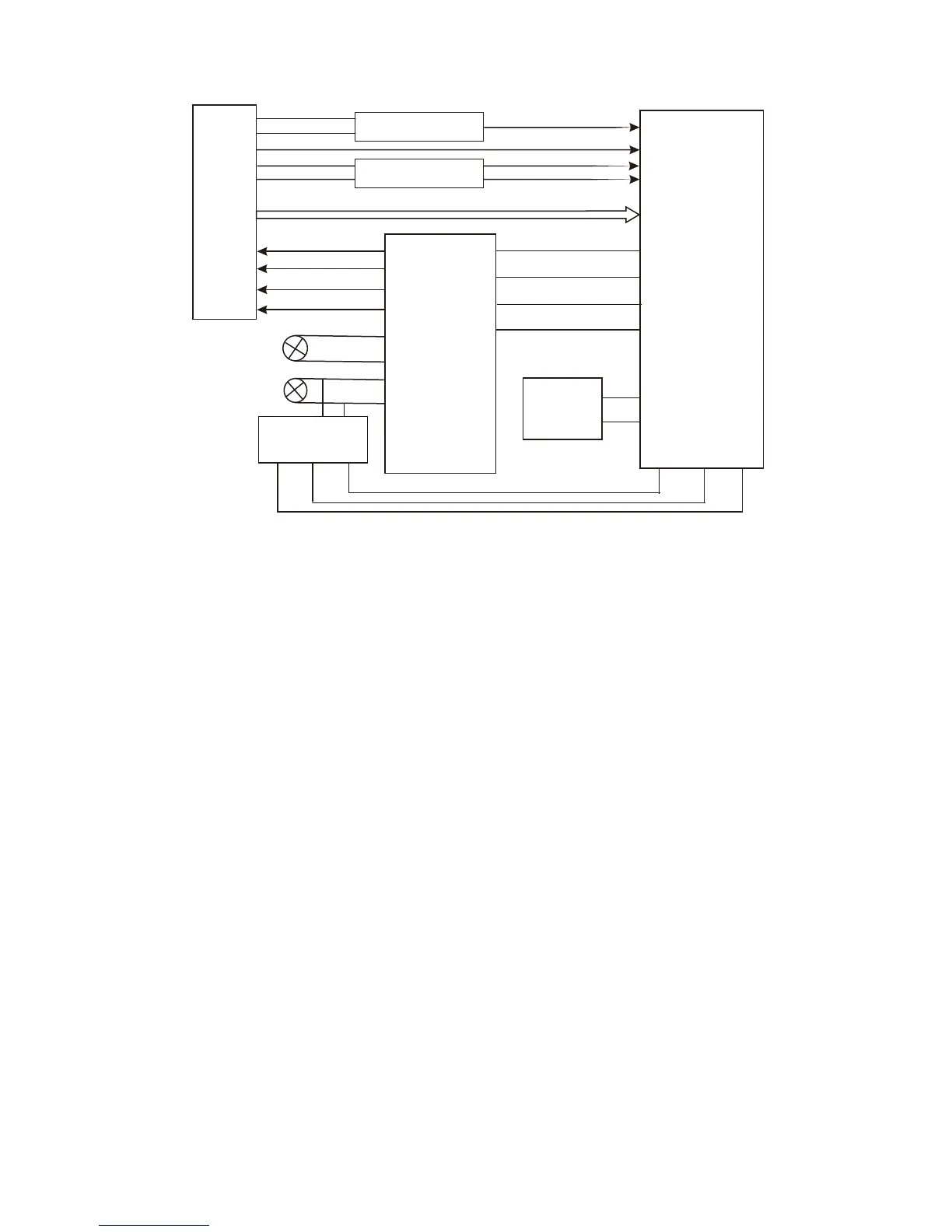

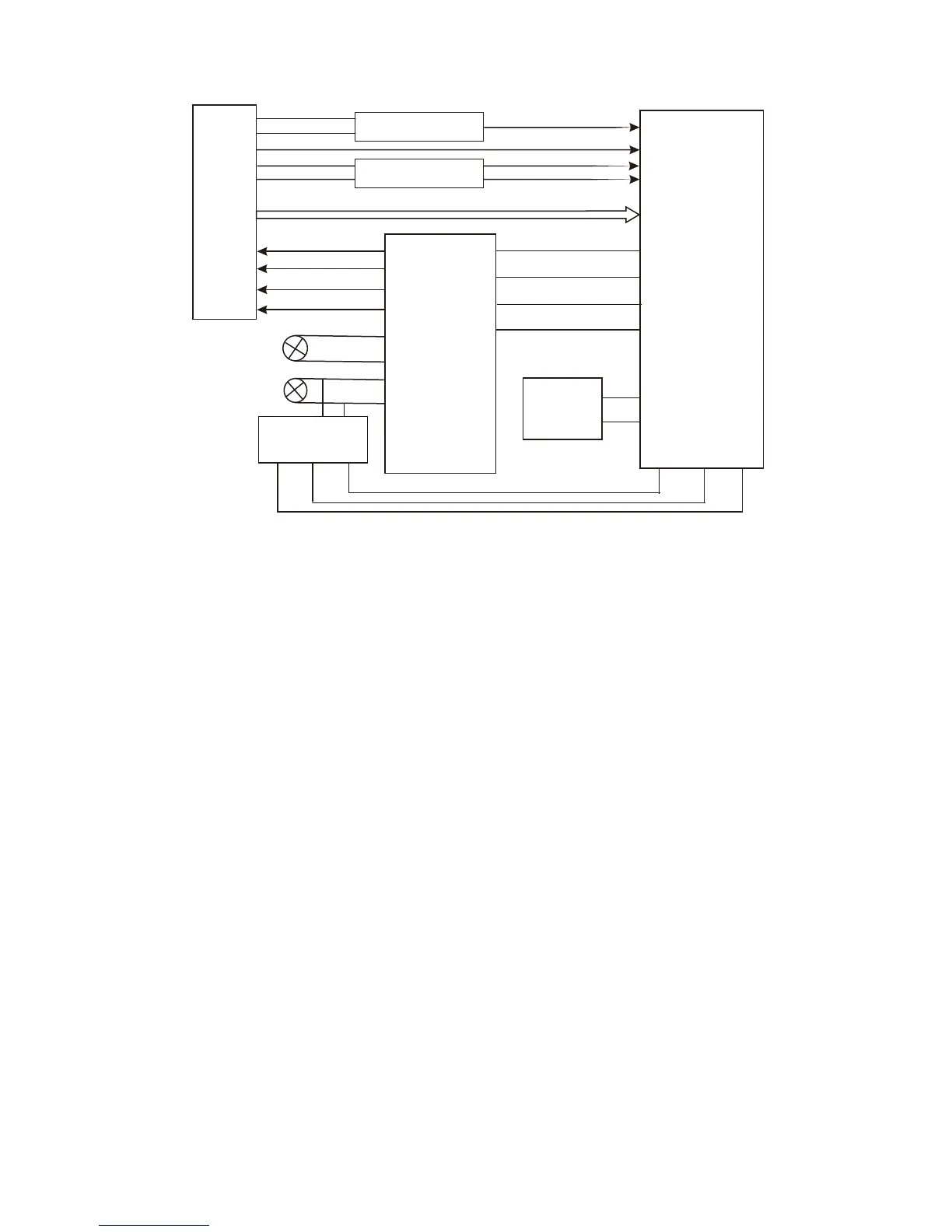

FOSO

FMSO

TRSO

DMSO

A B C D E F RFO

IOA

LDO2

LDO2

MD11

Switch circuit

APC circuit

Main axis

control detect

circuit

Main axis

electric

machine

Feed

electric

machine

XS101

AM5888

MT1389

Open/close

circuit

TK-

TK+

FC+

FC-

SL+

SL-

SP-

SP+

1

23

4

26

15

16

14

13

17

18

12

11

Figure 3.2.2.1 Servo circuit block diagram

2. Working principle: after power on or close to proper position, loader laser head begins to reset;

after laser head reaches proper position, detect switch will give a signal to Mt1389, Mt1389 begins to

output focus, main axis and light emission signals, machine begins to rotate, laser head begins to

identify disc information and decide whether disc is CD or DVD according to disc information to facilitate

to output level from IOA pin to make disc switch circuit and laser head PD IC make the relevant control

action. At the same time, Mt1389 adjusts laser output power through laser power control circuit.

After loader reading disc information, A, B, C, D, E, F signals are formed through photo-electric

conversion and sent out to Mt1389 (DVD only has A, B, C, D signals), and then inputted from pin 2~11,

18, 19 of MT1389. After being amplified and processed by the pre-amplifier inside MT1389, now signals

are separated to two part s for processing inside Mt1389. One part, through addition inside Mt1389 and

amplifying and subtraction circuit, produces servo error signal, after being processed by digital servo

signal circuit, corresponding servo control signals form to output FOO, TRO, DMO, FMO digital

servoControl signals from pin 42, pin 41, pin 37, pin 38 of Mt1389 respectively, and FOSO, TRSO,

DMSO, FMSO, through integration circuit composed by resistor capacitor, and send to servo driver

circuit for amplification to bring along focus winding, trace winding, main axis electric machine and feed

electric machine after drive amplification. Among these, focus and trace servo are used to correct

objective position accurately; feed servo is used to bring along laser head to make radial large-scale

move which belongs to the preliminary adjustment to laser head position; and main axis servo is used to

control main axis electric machine to make it read signals in means of constant linear velocity and

bringAlong disc to rotate. After processing of amplification by VGA voltage control amplifier and

- 18 -

Loading...

Loading...