7

4

1 2 3

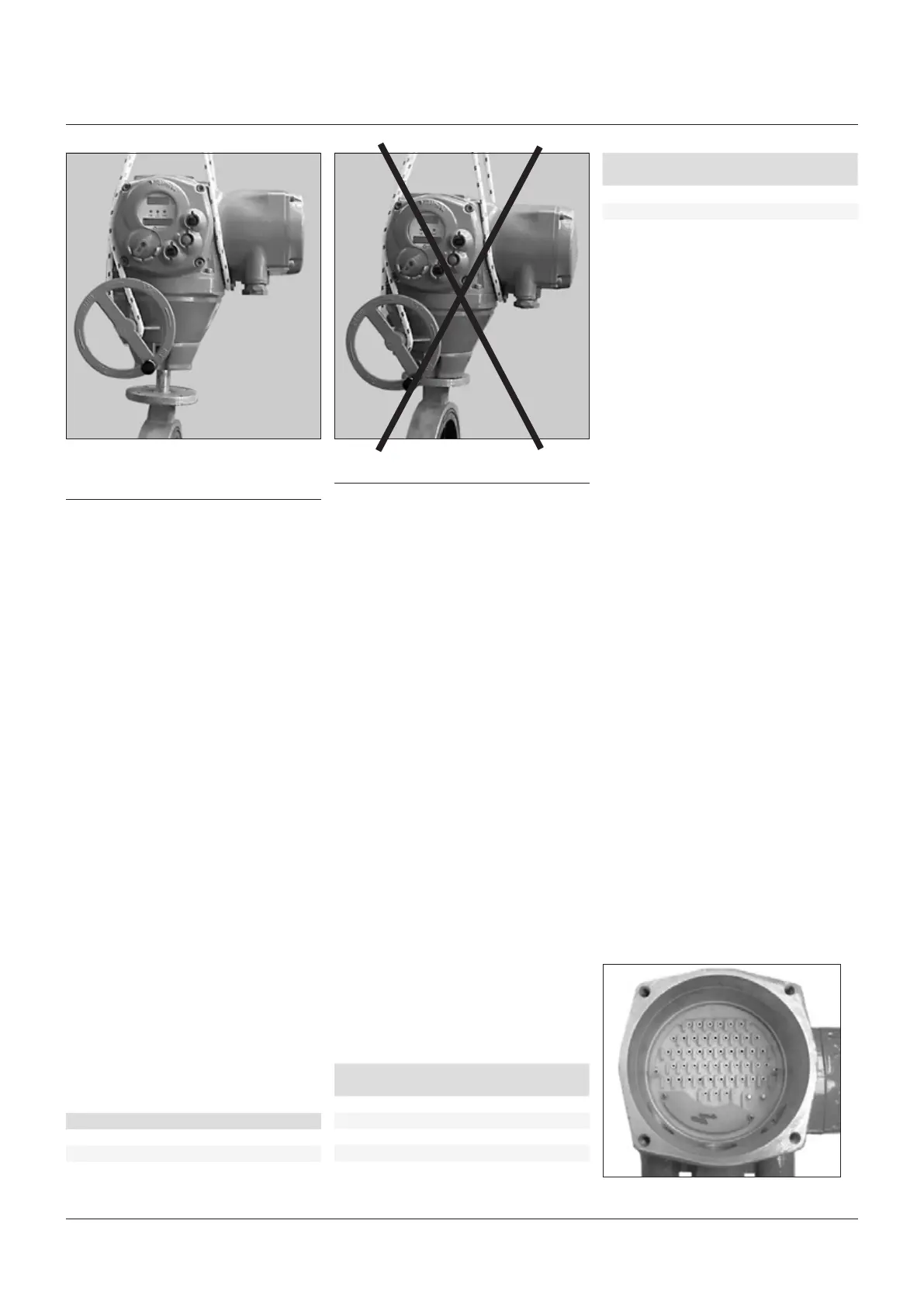

1 1" M32x1.5

2 1-½" M40x1.5

3 1" M32x1.5

4* ¾" M25x1.5

F01-2000/150 26

F01-2000/300 26

F01-2000/600 28

F01-2000/150 40

F01-2000/300 40

F01-2000/600 80

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

3�4 MOUNTING THE ACTUATOR ONTO

THEVALVE

Lubricate the valve stem.

Thoroughly clean the coupling surfaces of the

valve and actuator flanges, degreasing them

carefully since torque is transmitted by friction.

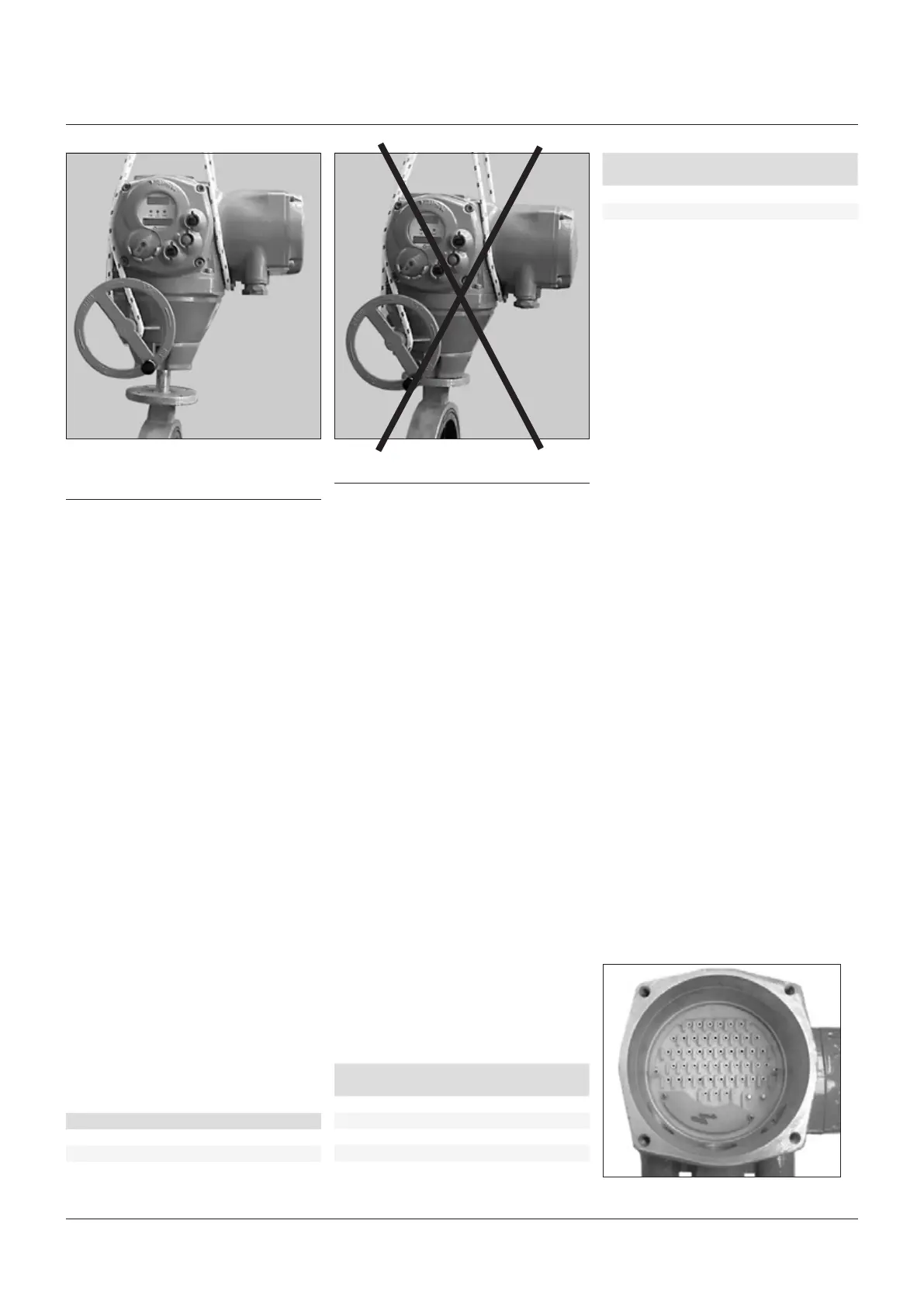

Lift the actuator with slings suitable for its

weight.

Size

(DN)

Max� weight

(kg)

WARNING

Never lift the valve/actuator assembly without

securing slings to both the valve and the actuator.

YES NO

Check the dimensions of the valve mounting

details, paying particular attention to the

protrusions of the valve stem in order to avoid

any axial thrusts to the internal parts of the

actuator or the valve when the screws are

tightened.

Place the actuator vertically on the valve stem.

Carry out the coupling operations (if necessary

with the help of manual operation); make sure

no mating parts are forced.

3�4�1 Actuator fixing

Model Tightening torque (Nm)

IMPORTANT

In case the actuator is supplied without stud bolts

and nuts the following materials must be used as

a minimum:

- ISO class 8.8 for studs bolts and nuts

or

- ASTM A 320 Grade L7 (or L7M) for studs bolts

- ASTM A 194 Grade 4 for nuts

3�5 ELECTRICAL CONNECTIONS

Before powering to the actuator check that the

supply voltage details on the nameplate are

correct for the plant. Access to terminals for

electrical connections and commissioning is

through the terminal cover, since all settings

are non-intrusive. The removal of any other

covers without Biffi’s approval will invalidate

the warranty.

Biffi will not accept any responsibility for any

damage or deterioration that may be caused.

IMPORTANT

All the accessories (in particular cable glands)

must be certified according to 94/9/EC Directive).

3�5�1 Identification of entries

Electric actuators series F01 2000 are equipped

with 4 entries (3 are standard the fourth is

supplied when requested).

With reference to the attached picture, the

thread form/size for entry is as follows:

3�5�2 Plants requirements

Protection devices (overcurrent breakers,

magneto-thermal switches or fuses) should

be provided on the plant at Customer care,

to protect the mains line in case of motor

overcurrent or loss of insulation between

phases and earth.

Entry

NPT

size

Metric size ISO 965

(alternative)

* optional

Loading...

Loading...