4

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

2 STORAGE AND

PRE-INSTALLATION

2�1 TESTS TO BE CARRIED OUT WHEN

THEACTUATOR IS RECEIVED

If the actuator is received already mounted

on the valve, all operations should have

already been performed during valve/actuator

assembly.

• Check that the display is active.

• Turn the handwheel until the valve is in a

completely open position.

• Check that the display reads 100% indicating

that the valve is completely open.

• Rotate the handwheel clockwise and bring

the valve to a completely closed position.

• Check that the display reads 0% indicating

that the valve is completely closed.

If the test result is satisfactory, the actuator

has already been adjusted and you can proceed

with the electrical connection.

If the actuator is delivered separately from the

valve, or the above procedure shows that the

position is incorrect, all operations described in

this manual must be carried out.

• Check that no damage has occurred during

transport, especially to the push-buttons, the

display area glass and the selector.

• Check the information on the nameplate:

serial number and performance data

(nominal torque, operation speed, protection

class, motor supply voltage, etc.), and verify

the corresponding data on the display

(seechapter 10, View routines).

Make sure all accessories have been received

with the shipment, as described in the delivery

documentation.

2�2 STORAGE PROCEDURE

IMPORTANT

Not performing the following procedures will

invalidate the product guarantee.

2�2�1 General

The actuator leaves the factory in perfect

condition, as guaranteed by an individual

test certificate. In order to maintain these

characteristics until the actuator is installed

on site, proper procedures must be taken for

preservation during the storage period.

Biffi actuators are weatherproof to IP68 for a

submersion at depth of 15 metres for 90 hours.

Thiscondition can only be maintained if the

units are correctly installed/connected on site

and if they have been correctly stored.

The standard plastic plugs used to close the

cable entries are not weatherproof, they just

prevent the entry of undesired objects during

transport.

2�2�2 Storage for a brief period

(less than one year)

2�2�2�1 Indoor storage

• Make sure that the actuators are kept in a dry

place, laid on a wooden pallet and protected

from dust.

2�2�2�2 Outdoor storage

• Make sure that the actuators are protected

from the direct action of weather agents

(protection by a canvas tarp or similar cover).

• Place the actuators on a wooden pallet, or

some other raised platform, so that they are

not in direct contact with the ground.

• If the actuators are supplied with standard

plastic plugs, remove them from the cable

entries and replace them with weatherproof

plugs.

2�2�3 Long period storage

(more than one year)

2�2�3�1 Indoor storage

(In addition to the instructions at

paragraph2.2.2.1)

• If the actuators are supplied with standard

plastic plugs, replace them with weatherproof

plugs.

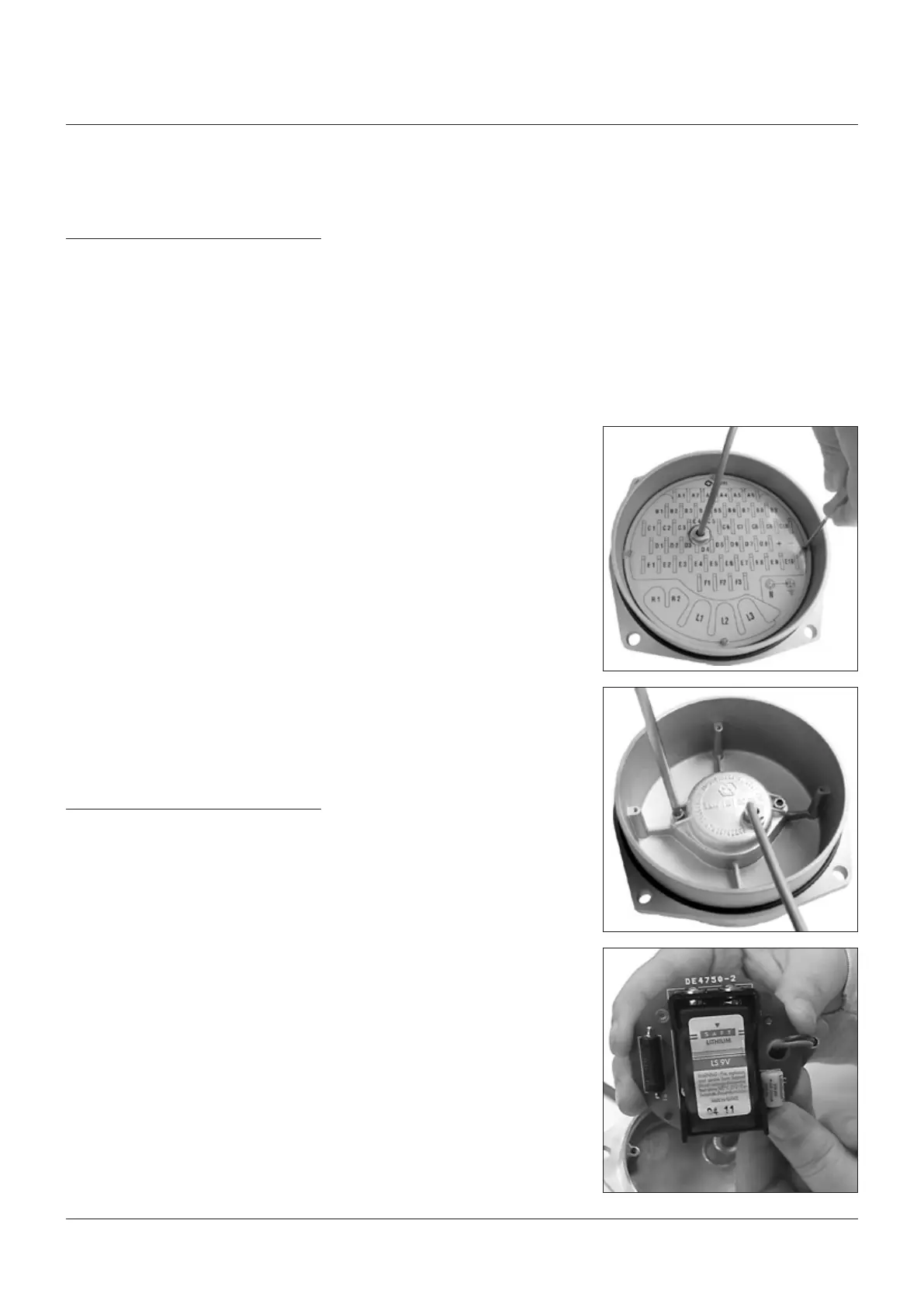

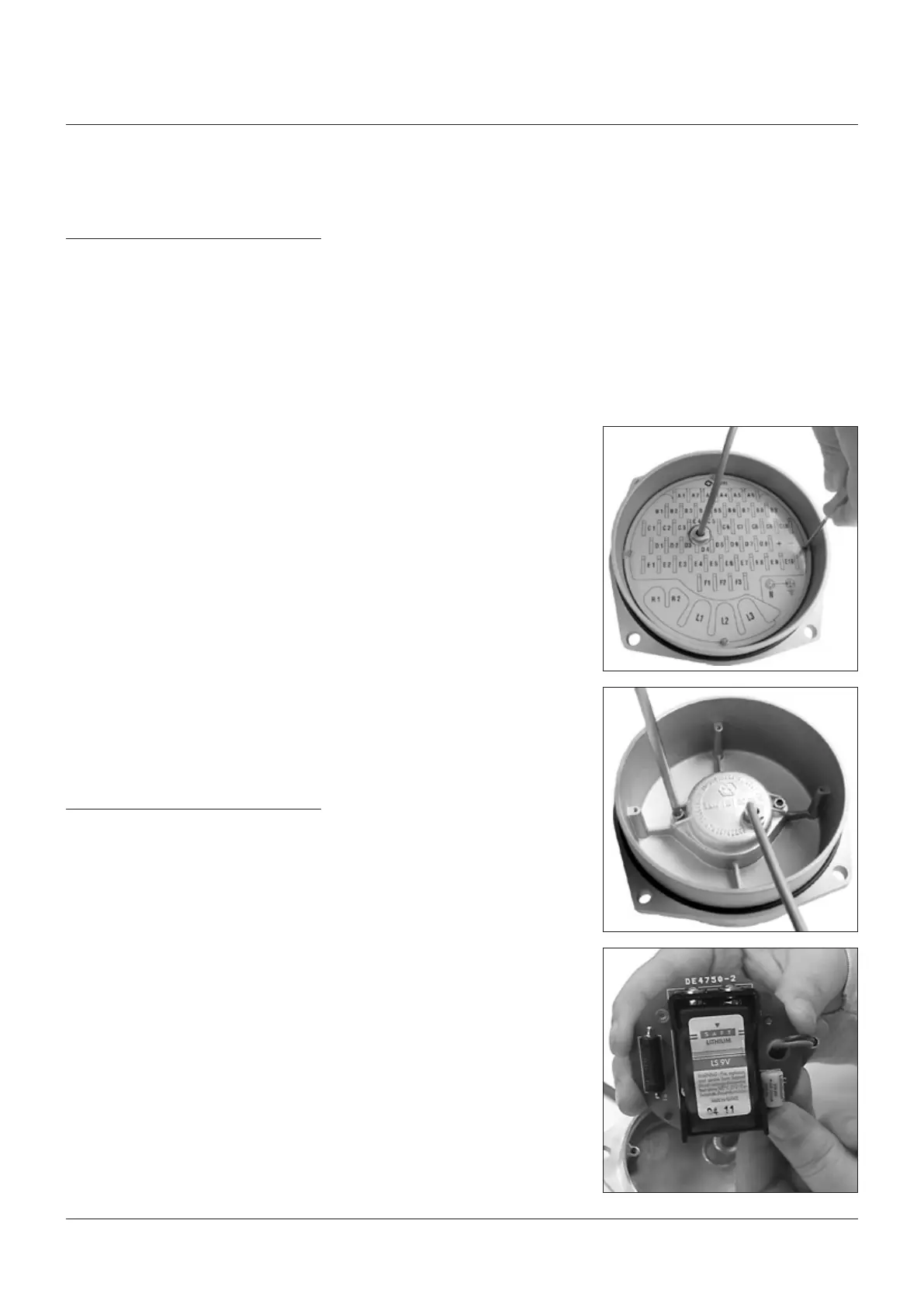

• In case the actuator is provided with an

lithium battery, remove it and store in dry and

clean place (see paragraph 11.3, Maintenance

- Lithium battery change)

2�2�3�2 Outdoor storage

(In addition to paragraph 2.2.2.2)

• Check the general conditions of the actuator,

paying particular attention to the terminal

board, fuse enclosure and local display glass.

• In case the actuator is provided with an

lithium battery, remove it and store in dry and

clean place (see paragraph 11.3, Maintenance

- Lithium battery change).

Loading...

Loading...