9

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

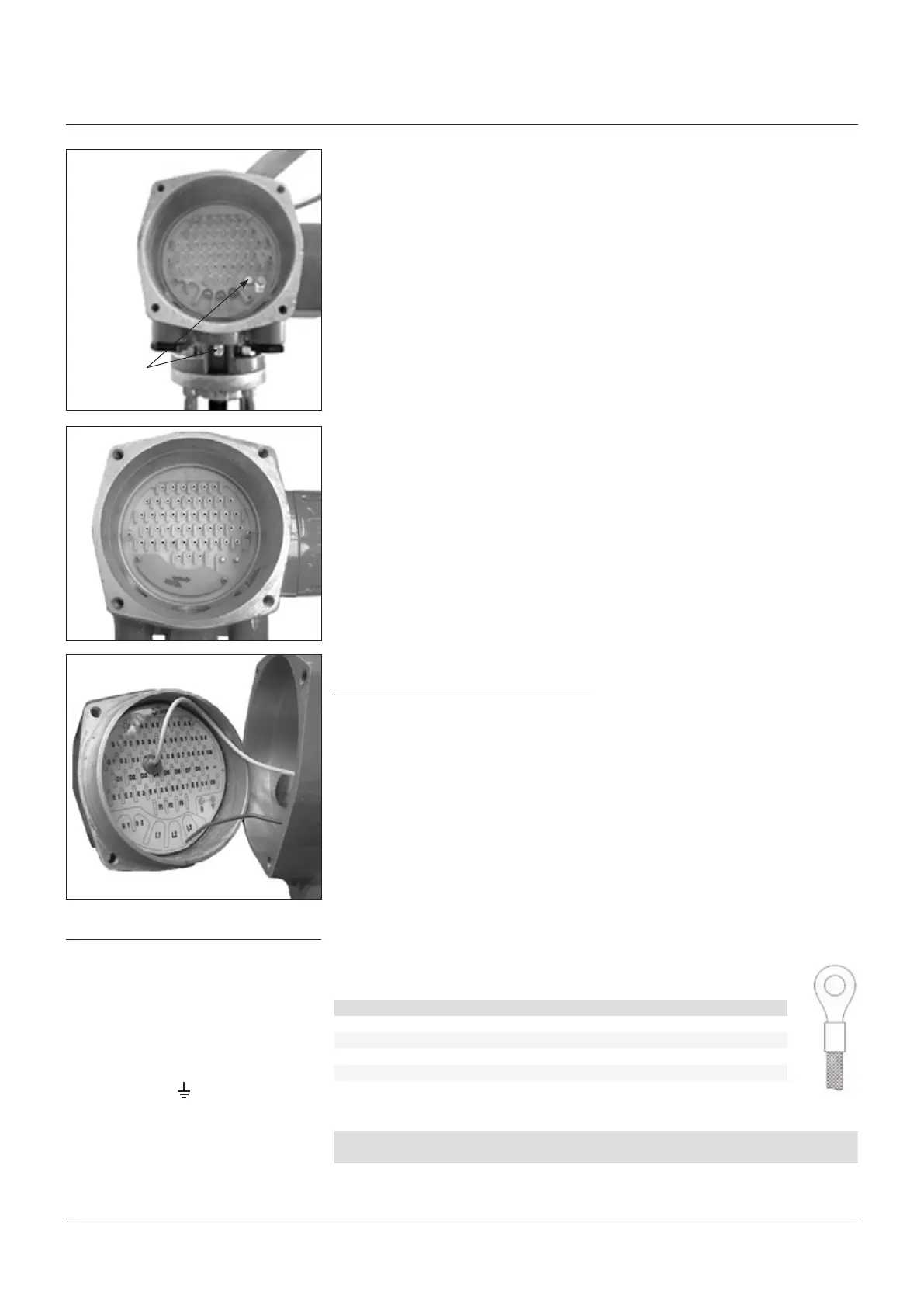

Terminate the ground connections to the

ground stud marked One internal

andoneexternal ground studs are provided.

Check the wiring diagram (always enclosed

with the actuator) and the layout displayed

on the back of the terminals enclosure cover,

to ensure a correct electrical connection.

3�9 INSTRUCTIONS FOR THE

EXPLOSIONPROOF ENCLOSURES

IMPORTANT

Electric actuator F01-2000 shall be installed

and maintained according to the applicable

rules regarding the electrical installations in

hazardous area (other than mines) classified

as zone 1 (gas); example: EN 60079-10

(hazardousareaclassification), EN 60079-14

(electrical installation), EN 60079-17

(maintenance), and/or other national standards.

During the dismantling and subsequent

reassembling of the explosionproof enclosures

(covers, cable glands, joints) be careful to bring

these enclosures back to their original condition

3�8 TERMINAL BOARD

Ground studs

IMPORTANT

The removal of any other covers without Biffi’s

approval will invalidate the warranty. Biffi will

not accept any responsibility for any damage or

deterioration that may occur as a result of cover

removal.

Allterminations should be made by insulated

ring or spade connectors using the appropriate

crimping tool. This operation will ensure easy

and correct electrical connection.

Connect the motor supply cable previously

sized in accordance with:

- The absorbed current correspondent to the

actuator nominal torque with the torque

limiting device set at 100 percent (see the test

certificate attached to the actuator).

- The applicable plant and safety norms.

Assemble the power terminals protective

barrier, located in the terminal board

compartment, using the enclosed screws.

The control circuit (controls and signals) must

be connected by means of a multicore cable

to the corresponding numbered terminals

according to the wiring diagram.

The internal cables of the actuator are also

numbered according to the wiring diagram.

Actuators are always delivered with the

motors wound and connected in accordance

to customer requests. Voltage and frequency

values are stated on the motor nameplate.

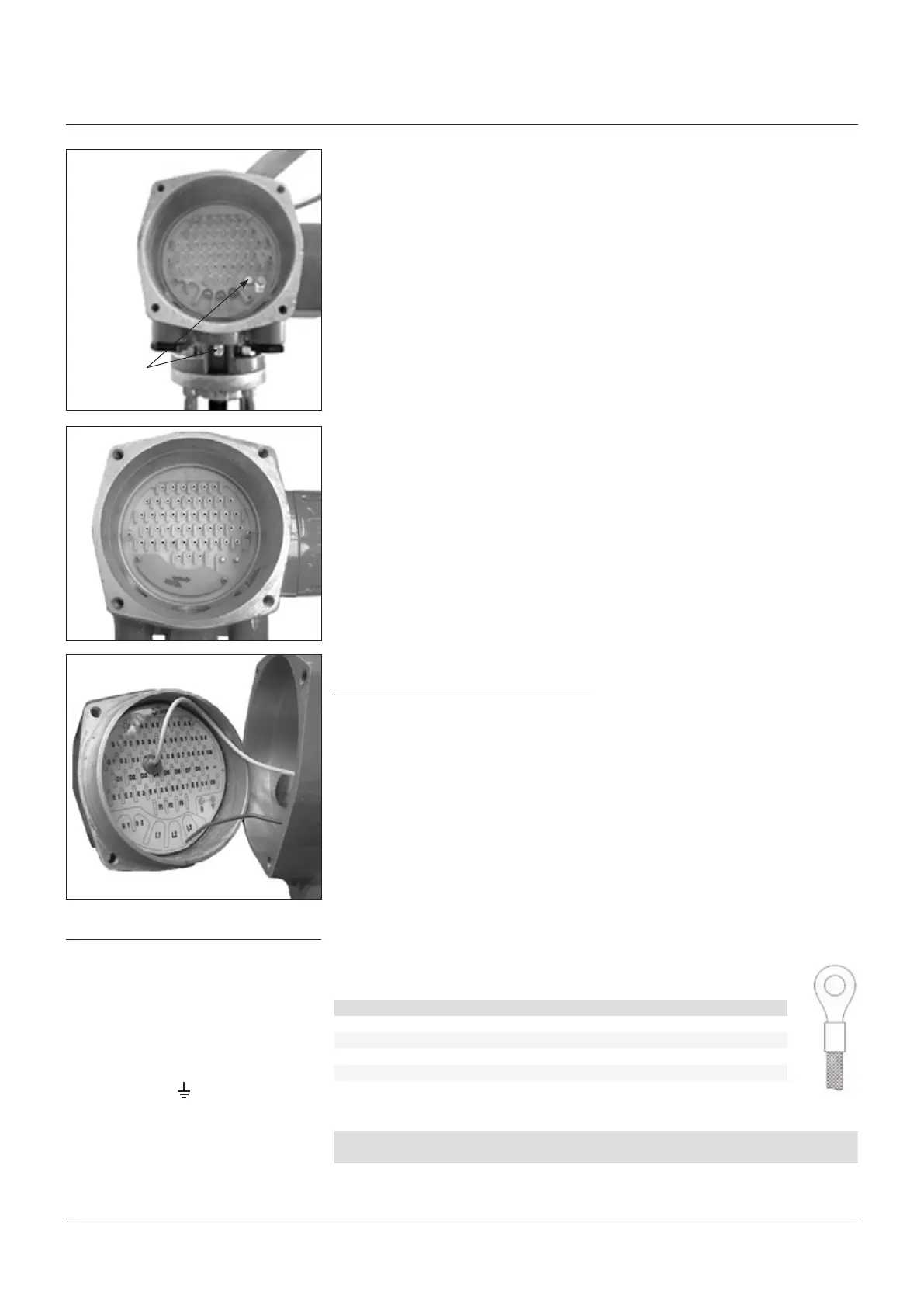

Connections for Ex e terminals enclosure

The wires must be terminated in accordance

with the following method (see connection table

below):

CONNECTION TABLE

Power cables Control cables

Type of terminal Insulated ring tongue

Eye dimensions (mm) 5.50 3.20

Recommended tightening torques (Nm) 2.0 - 2.8 1.0 - 1.5

Wires section (mm

2

) 4 2.5

BOLTING TABLE

Model

Motor

cover

Terminal enclosure/

local interface covers Material

F01 M10x35 M10x30 AISI 316/ASME B16.11 A182-F316 (yield strength ≥ 450N/mm

2

)

to maintain their integrity. In particular, be

sure the joint surfaces of all enclosures are

spread with a film of recommended grease

(seechapter4, Lubrication).

So please:

• Do not damage the explosionproof mating

surfaces on the housing and on the electrical

enclosures covers.

• Reinstall all the screws that go with the

dismantled parts, and block them with a

thread sealant after spreading them with

a film of copper- or molybdenum-based

grease. This will keep screws from sticking

and make maintenance operations easier.

• Check that the bolts and screws are the

same dimension and quality as the original

ones (see bolting table below), or of a

betterquality.

Loading...

Loading...