The F02 unit can be installed onto the valve in two different ways:

Direct mounting: insert the valve shaft into the actuator bottom flange,

taking care to correctly connect the insert. Fix the screws on the

valve flange to the actuator coupling block.

Bracket mounting: install the bracket and the adapter onto the valve; then insert the

valve shaft into the actuator bottom flange, taking care to correctly

connect the insert.

Fix the screws between the bracket and the valve flange and the

actuator coupling block.

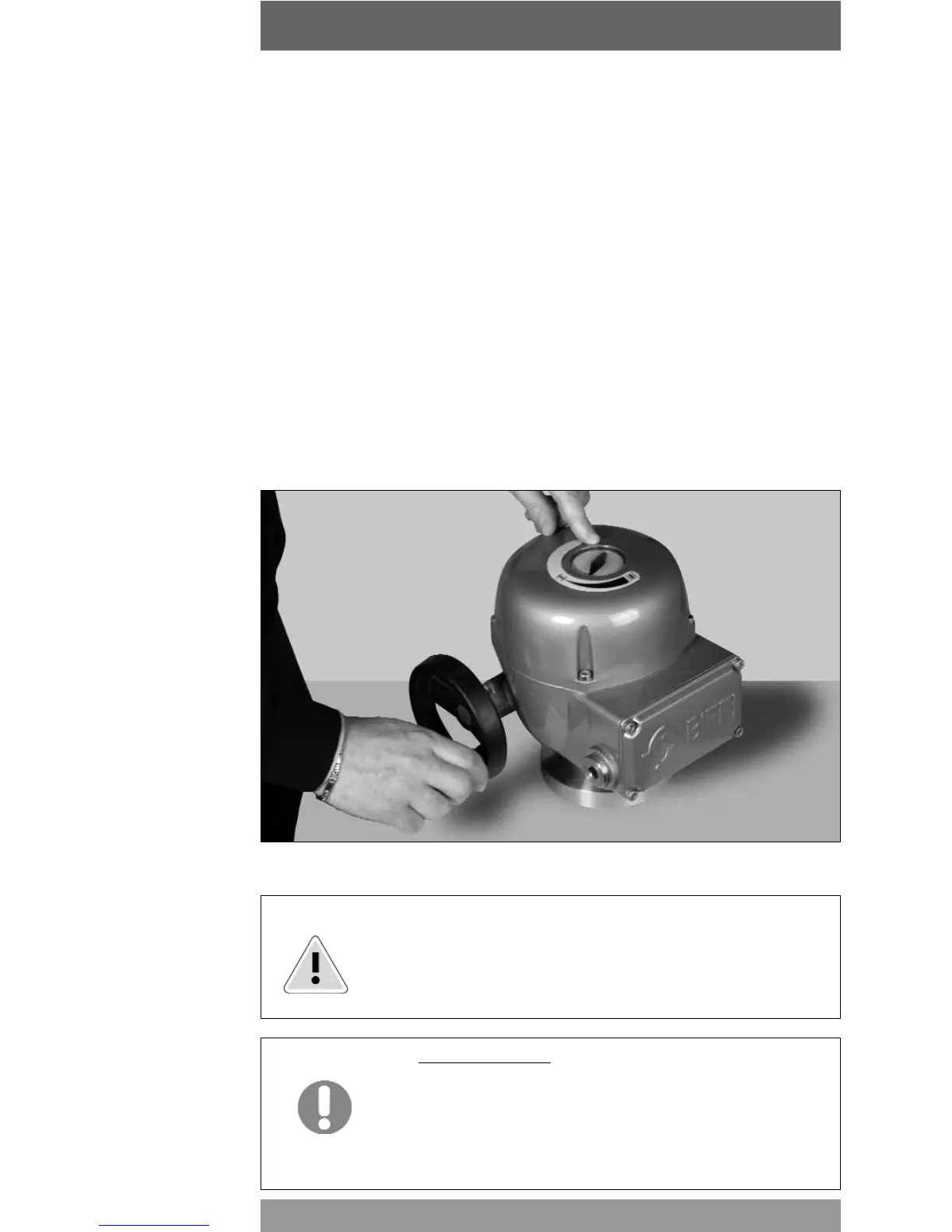

4.5 Manual operation

F02 electric actuators are supplied with a handwheel for manual override as standard, to

operate the actuator in case of power supply failure or during setting.

The handwheel is always engaged. For safe operation, the handwheel does not rotate

during electric operation.

Turn the handwheel clockwise to close and counter-clockwise to open.

During manual operation, check the actuator manoeuvre on the local mechanical indicator.

Warning: Do not manually operate the actuator with devices other than

the handwheel. Using cheater bars, wheel wrenches, pipe

wrenches, or other such devices on the actuator handwheel

may cause serious personal injury and/or damage to the

actuator or valve.

Important: Handwheel rotation

In standard applications clockwise rotation of the handwheel

moves the valve to close position and counter-clockwise

rotation moves the valve to open position.

Different operation must be clearly indicated on the

handwheel.

13

© Copyright by BIFFI Italia. All rights reserved.

A !@#$ INTERNATIONAL LTD. COMPANY

F02 Quarter-turn Electric Actuators

instruction and operating manual

Manual operation.

Loading...

Loading...