22

© Copyright by BIFFI Italia. All rights reserved.

A !@#$ INTERNATIONAL LTD. COMPANY

F02 Quarter-turn Electric Actuators

instruction and operating manual

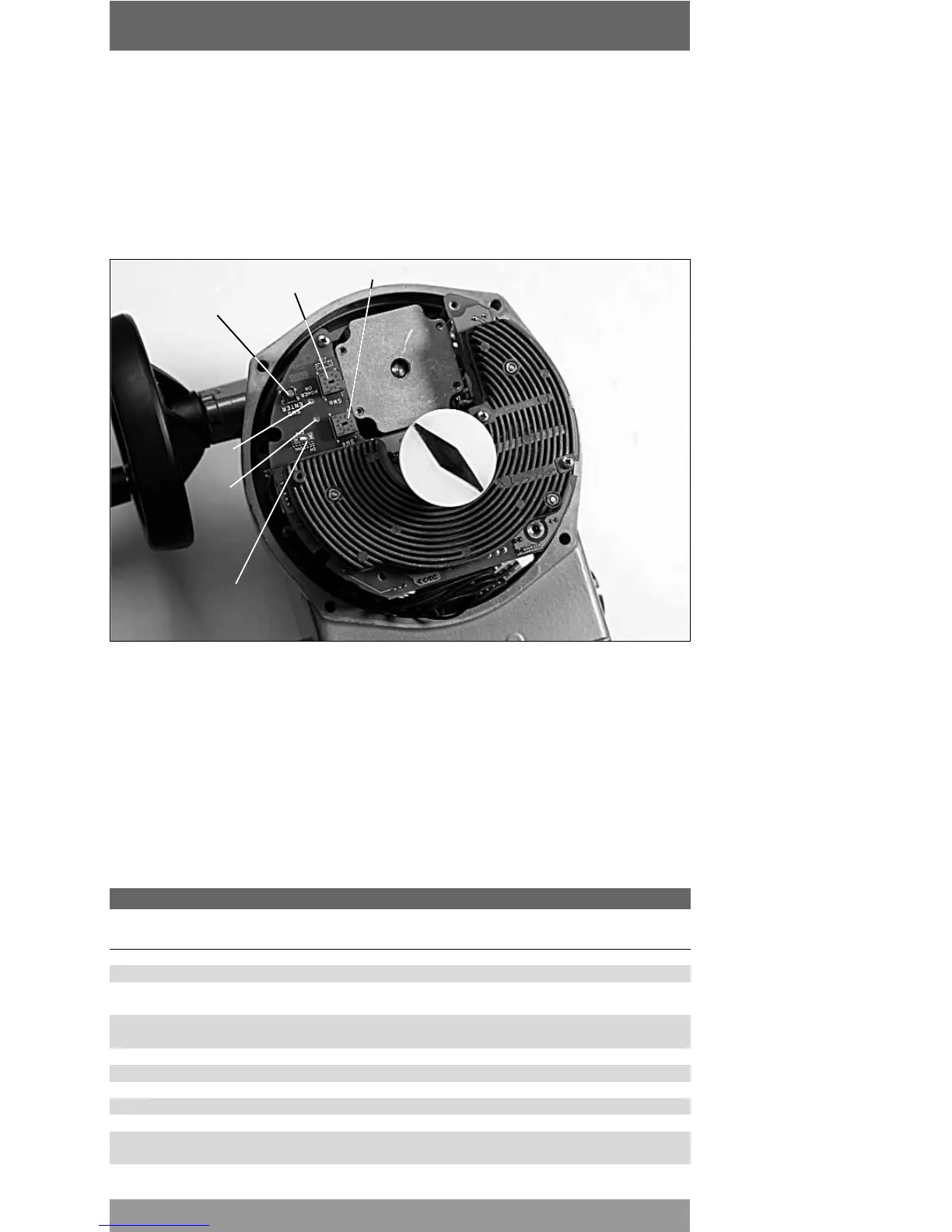

F02 internal control panel and setting tools.

Rotary selector switch SW6

Rotary selector switch SW4

Pushbutton SW5

Green LED:

Power on

Red LED:

Enter

confirmation

Selector switch SW3

The setting of the actuator parameters is done through the following tools:

- two rotary selector switches SW6 and SW4 for actuator setting;

- Enter push-button SW5 (confirmation push-button);

- dip-switch SW3 (enable setting function);

- green LED indicating power On (switched on when power supply is available).

- red LED for Enter confirmation (blinking once setting is confirmed);

- mechanical stops.

6.2.2 ACTUATOR MODEL SELECTION

The frames relevant to models 63/125 and 250/500 can be set to operate with a 63Nm or

125Nm motor and a 250Nm or 500Nm motor respectively.

The difference is based on the technical characteristics of the electric motor itself.

The selection of the actuator model must be done through selector switches SW4 and SW6

as indicated in the following setting table.

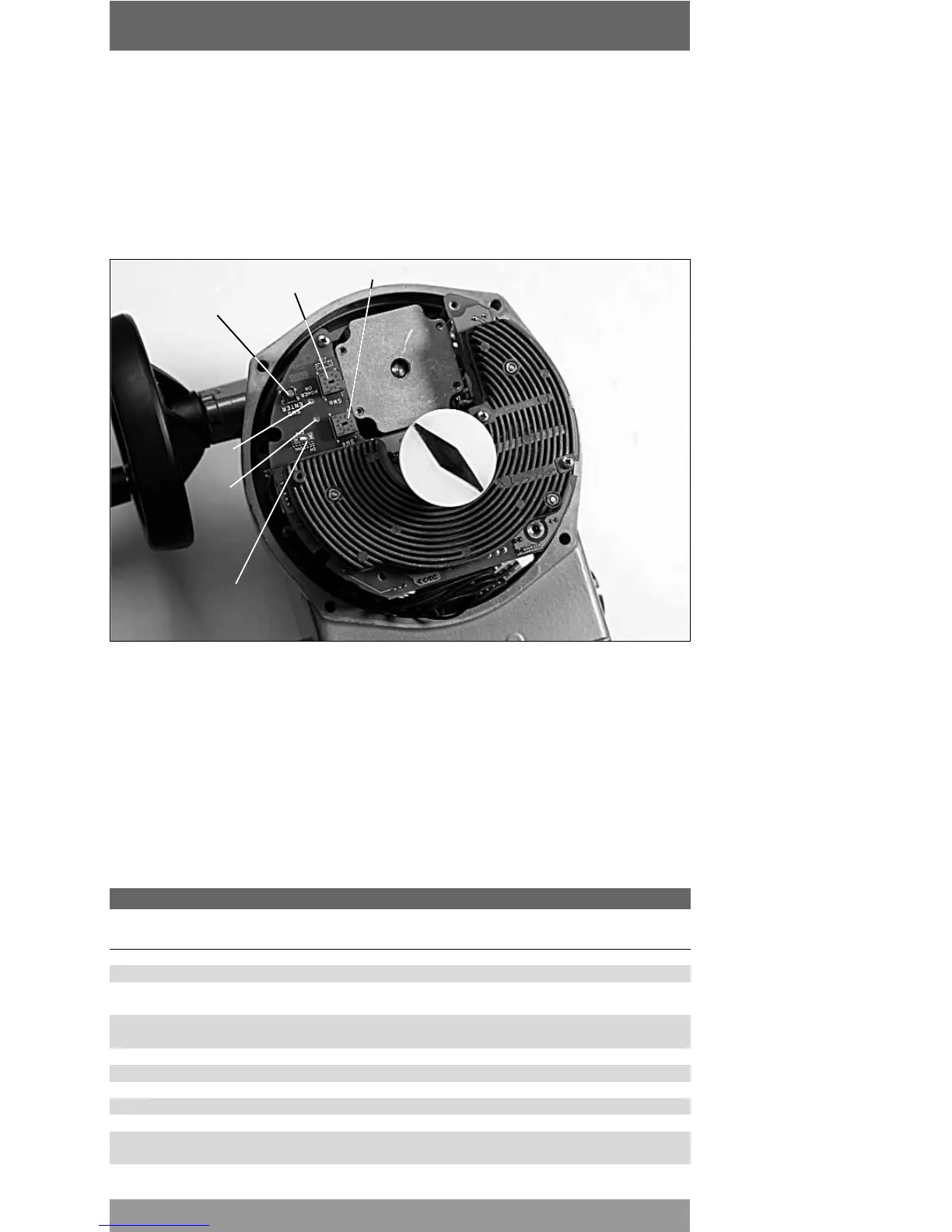

F02 configuration and setting table

Switch SW4 SW6 SW5 SW3

Enter Setting Default

pushbutton function values

Close limit 0 0 1 1

Open limit 1 0 1 1

Limit switch closing 2 1: position 1 1 position

0: torque

Limit switch opening 3 1: position 1 1 position

0: torque

Closing stroking time 4 0 to 9 1 1 7

Opening stroking time 5 0 to 9 1 1 7

Torque CL 6 0 to 9 1 1 9

Torque OP 7 0 to 9 1 1 9

Reverse mode (CCW) 8 0 = off; 1 = on 1 1 OFF

Size 9 0: 63Nm (250 Nm) 1 1 63 Nm or

1: 125Nm (500/1000 Nm) 250Nm

Loading...

Loading...