VD (E2.1) 07/2017 page 54/96

14.1 Evacuation

• VD 23: Close the air/gas valve (4).

• VD 53 and VD 115: Close the aeration valve (5) and the fine dosing valve for inert gas (6).

• Turn on the vacuum pump.

• Put the lever of the vacuum shut off valve (8) to

“ON” position (valve open).

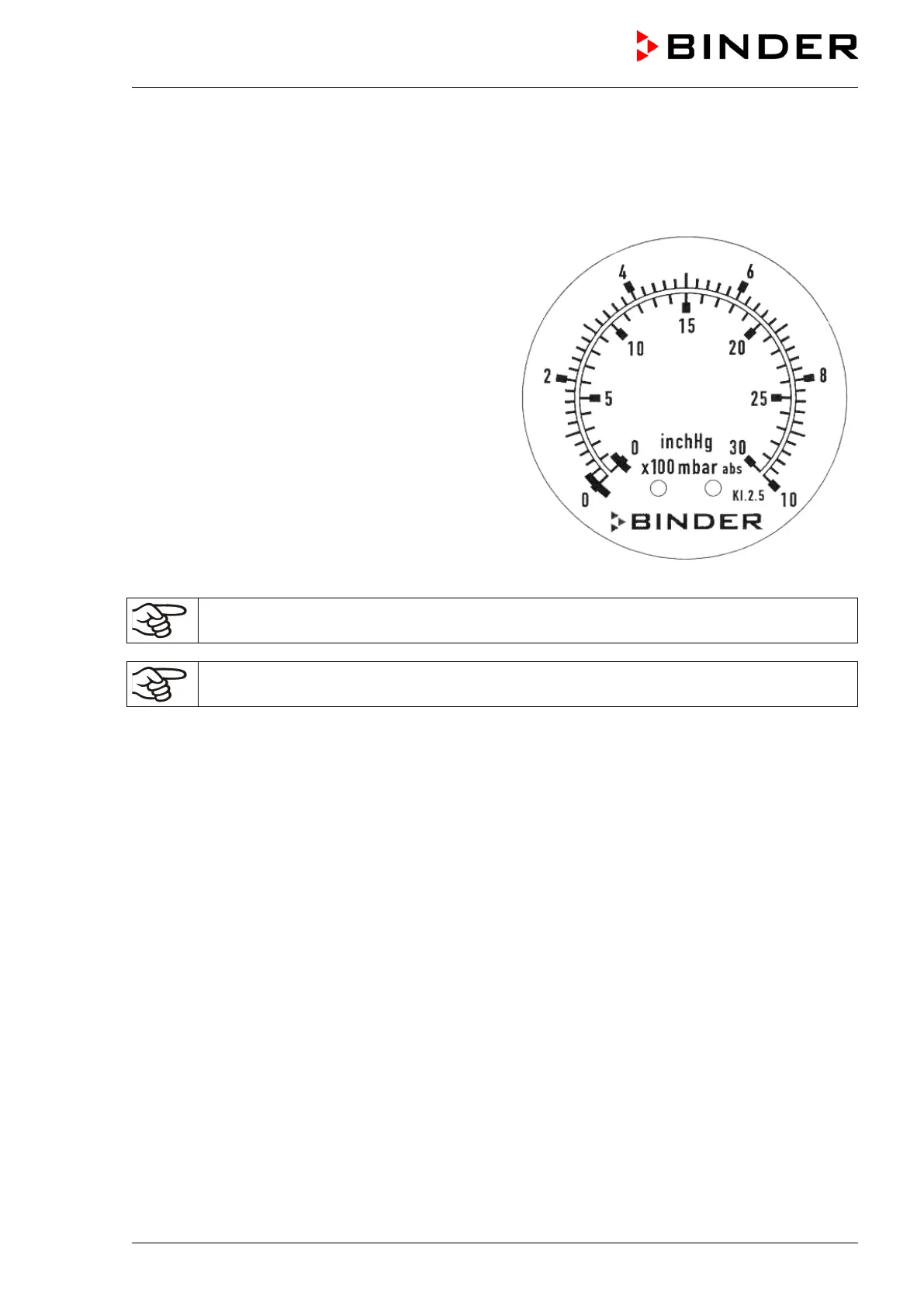

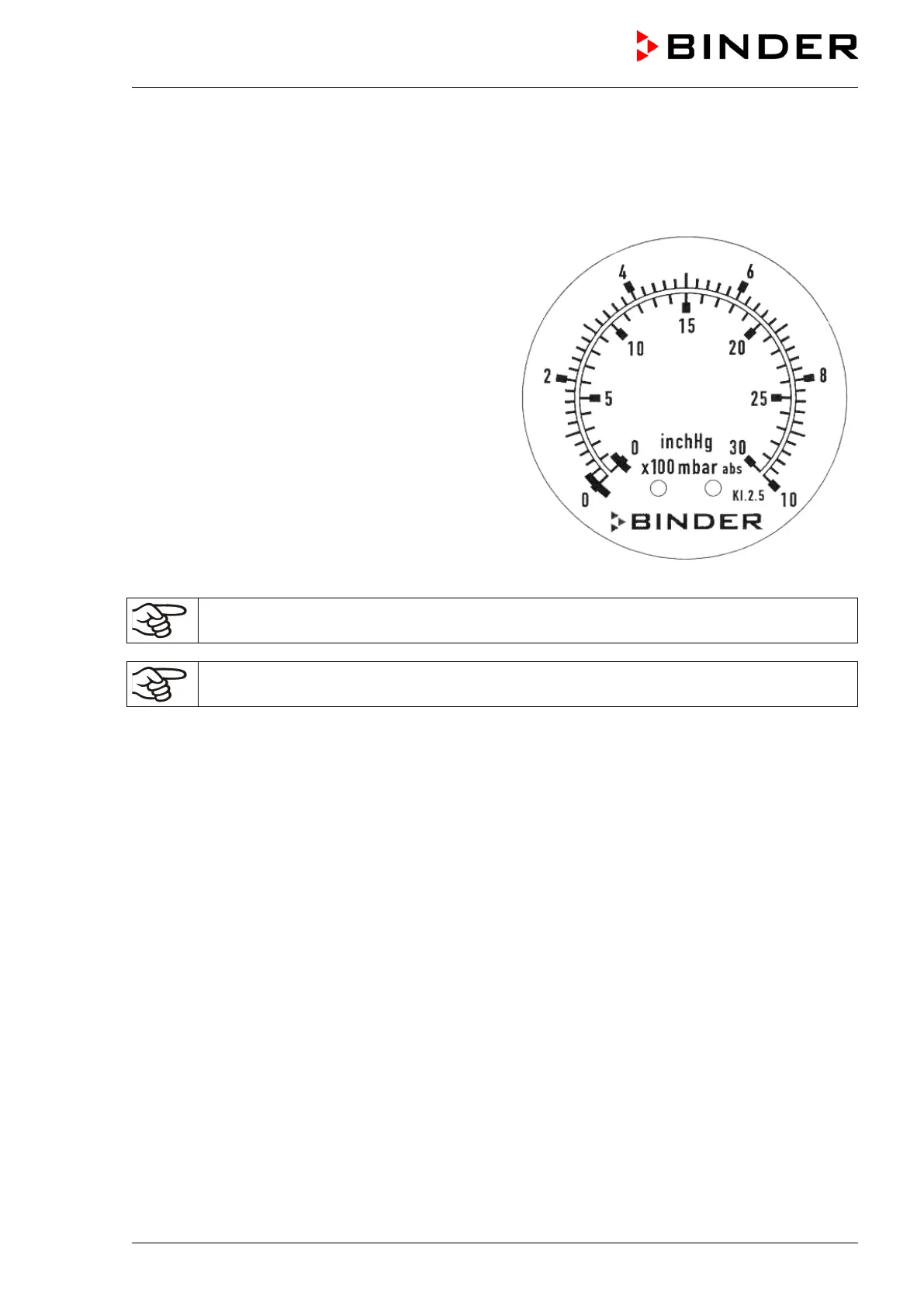

• Monitor the internal pressure on the pressure

display (3). The analog manometer displays the

running evaporation respectively the end of the

drying procedure. The scale of the manometer (3)

refers to an ideal ambient pressure of 1013 mbar

/ 29.9 inHg. Tolerance: 50 mbar / 37.5 mm Hg

(Torr) / 1.48 inch Hg (2.5% of the final scale value

+ reading precision). The optional digital pressure

display (chap. 16.5) offers an absolute scale.

• When the desired end vacuum is obtained, turn

the VDL vacuum shutoff valve (8) to the “OFF”

position (valve closed). The reached vacuum is

now maintained.

Figure 12: Manometer display

The permissible end vacuum is 10

-2

mbar / 0.0003 inHg.

As long as there is a vacuum, never try to open the oven by force.

14.2 Breaking the vacuum (flooding with ambient air)

When the drying procedure is complete, the vacuum in the inner container is broken (flooded).

VD 23:

• Open air/gas valve (4)

Fresh air is sucked in through the inert gas connection (12)

VD 53, VD 115:

• Open aeration valve (5)

Fresh air is sucked in through the lateral ventilation slots of the instrument box.

• Open fine dosing valve for inert gas (6)

Fresh air is sucked in through the inert gas connection (12)

The fresh air is introduced into the lower part of the rear panel of the inner chamber and is evenly

distributed in the inner chamber. This supply of fresh air by under-flooding prevents turbulence of

pulverized drying material.

Loading...

Loading...