22

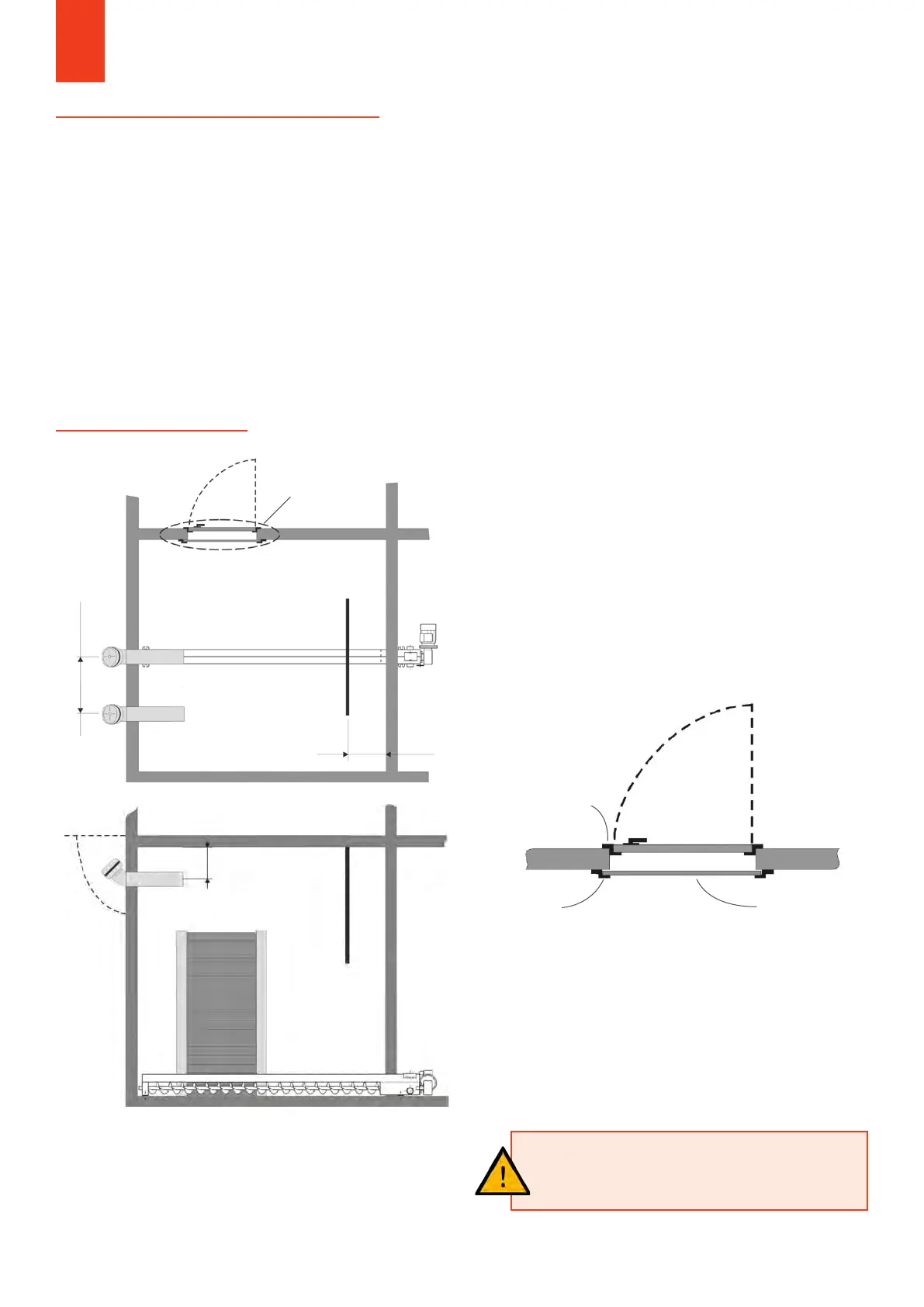

Dichtung

Z-Profil

Holzbretter

(min. 30 mm)

The storage room must be periodically cleaned of fine particle

deposits. Appropriate accessibility must therefore be provided.

BEARING VENTILATION

Carbon monoxide (CO) may be released during storage of the

pellets. This is a non-irritating, toxic gas which is colourless,

odourless and tasteless. Odours can be caused by the release of

volatile hydrocarbons (VOC).

In order to be able to enter the pellet store safely at all times,

constant ventilation of the room must be ensured. This can be

done with the help of ventilating covers. These must be fitted to

both the filling and the extraction nozzles. Before entering the

warehouse, it should be well ventilated for at least 15 minutes. It

is very important to enter the pellet store only in the company

of a second person, who should be outside the danger zone

for safety reasons. The pellet store should not be entered for

four weeks after filling. If this is nevertheless necessary, the CO

content should be measured beforehand, e.g. with a mobile CO

warning device. A store buried underground as well as a pellet

store with a content of more than 15 tonnes must always be

entered with a CO warning device attached to the body.

Stickers with these safety instructions must be placed in a clearly

visible position at the entrance to the storage facility.

DIN EN ISO 20023 and VDI Guideline 3464 regulate the

ventilation of pellet stores.

6.4 MAINTENANCE

PLANING FOLDER PELLET BOILER

DETAIL DOOR

For storage quantities ≤ 15,000 kg, there are no fire protection

requirements for doors or hatches to the pellet store. Doors

and hatches must open outwards and be fitted with a

circumferential seal (dust-tight). For doors or hatches to the

pellet store, wooden boards must be fitted on the inside to

relieve pressure so that the pellets do not press against the door

or hatch. The door handle must be removed from the inside.

The door lock must be sealed dust-tight from the inside.

ATTENTION:

Observe country-specific

regulations!

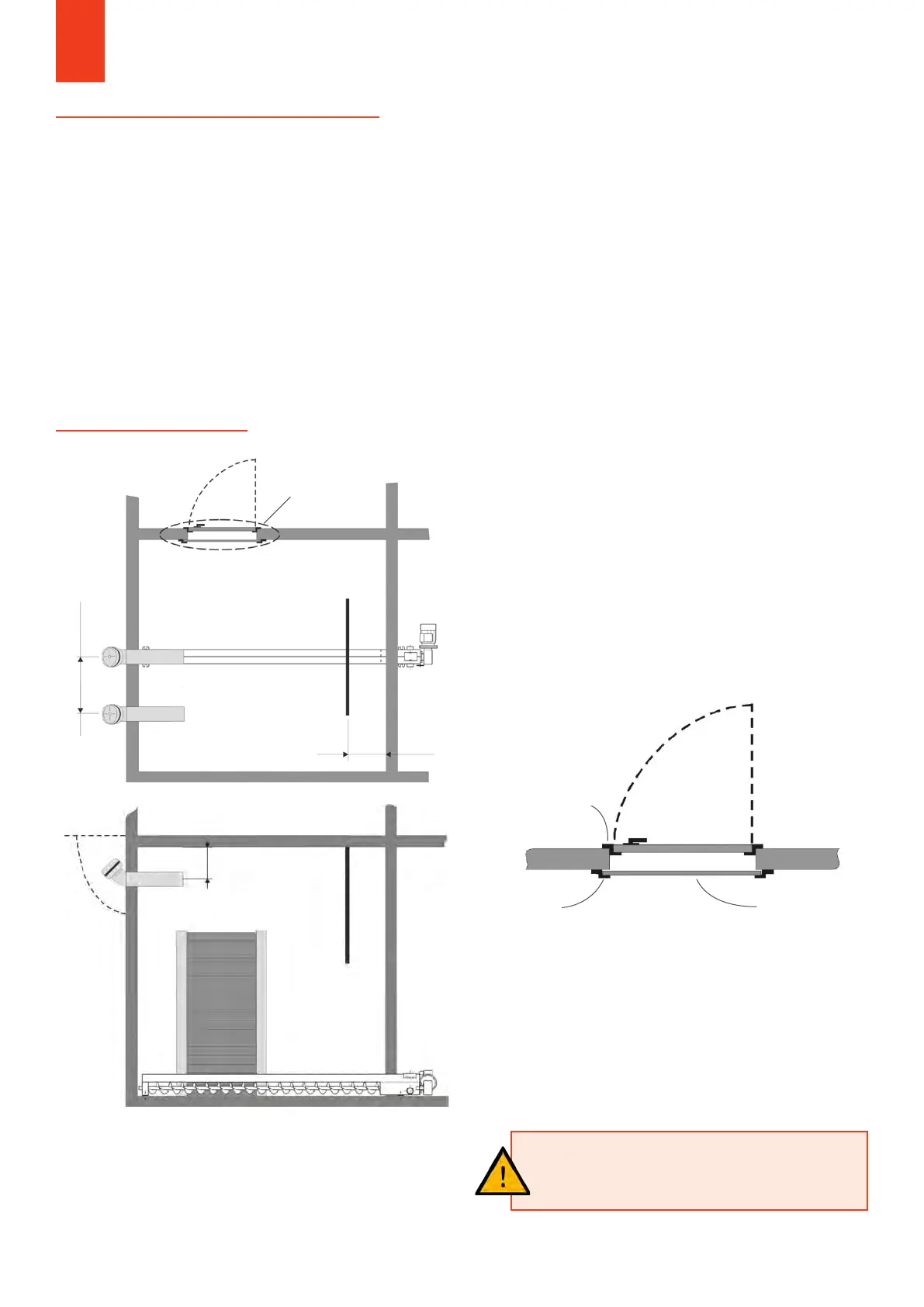

DETAIL IMPACT PROTECTION MAT

The impact protection mat (1000x1250 mm) protects the

pellets against from breaking when they hit the storage room

wall. Furthermore, the wall itself is protected from damage.

The impact protection mat consists of an abrasion-resistant

and ageing-resistant plastic with a fastening option for ceiling

mounting and a downward tensioning option (trampoline

eect). It is mounted opposite the filling spout.

6.5 FLOOR PLAN/SECTION PELLET STORAGE ROOM

min. 200

Wooden boards

Impact mat

Door

(see detailed view)

Screw discharge

Inlet & outlet spigots

Storz “A“

min. 500

min. 300

All dimensions in mm!

ATTENTION:

The distance between the wall and the impact

mat must be at least 300 mm!

Loading...

Loading...