24

PLANING FOLDER PELLET BOILER

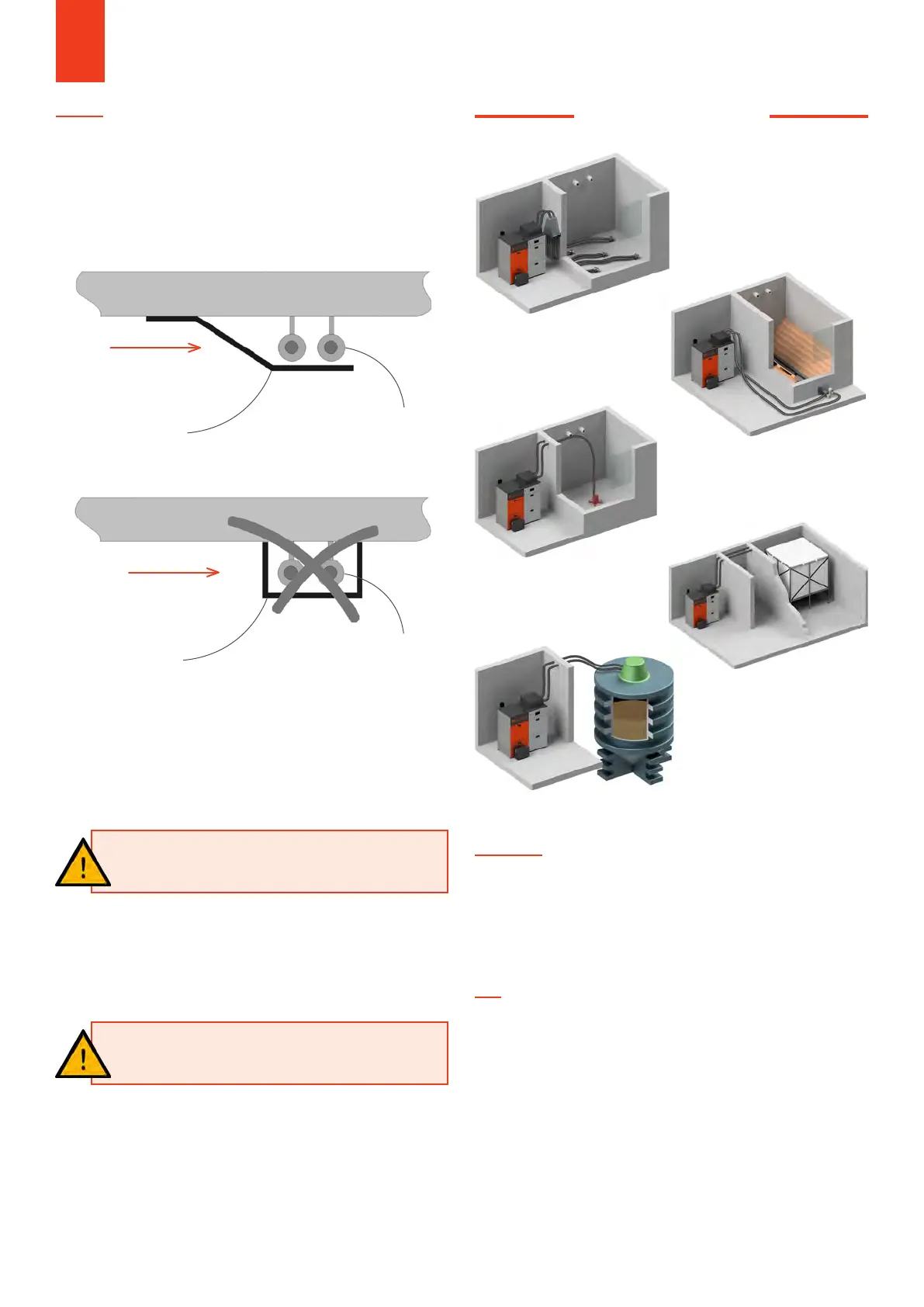

Existing pipelines, drainage pipes, etc. that cannot be

removed with reasonable eort and onto which the

pellets could collide during filling must be covered

to prevent flow and breakage (e.g. deflector plates).

Make sure that the pellets cannot be damaged by the

deflector plate (no rectangular cladding).

ELECTRICAL CONNECTION

The boiler requires a separate 230 V 50 Hz power

supply. The mains supply line must be protected with

a 16A category B circuit breaker. We recommend

installing an emergency heating switch.

ELECTRICAL INSTALLATION IN THE PELLET STORAGE

There must be no electrical installations such as switches,

lights, junction boxes, etc. in the pellet storage!

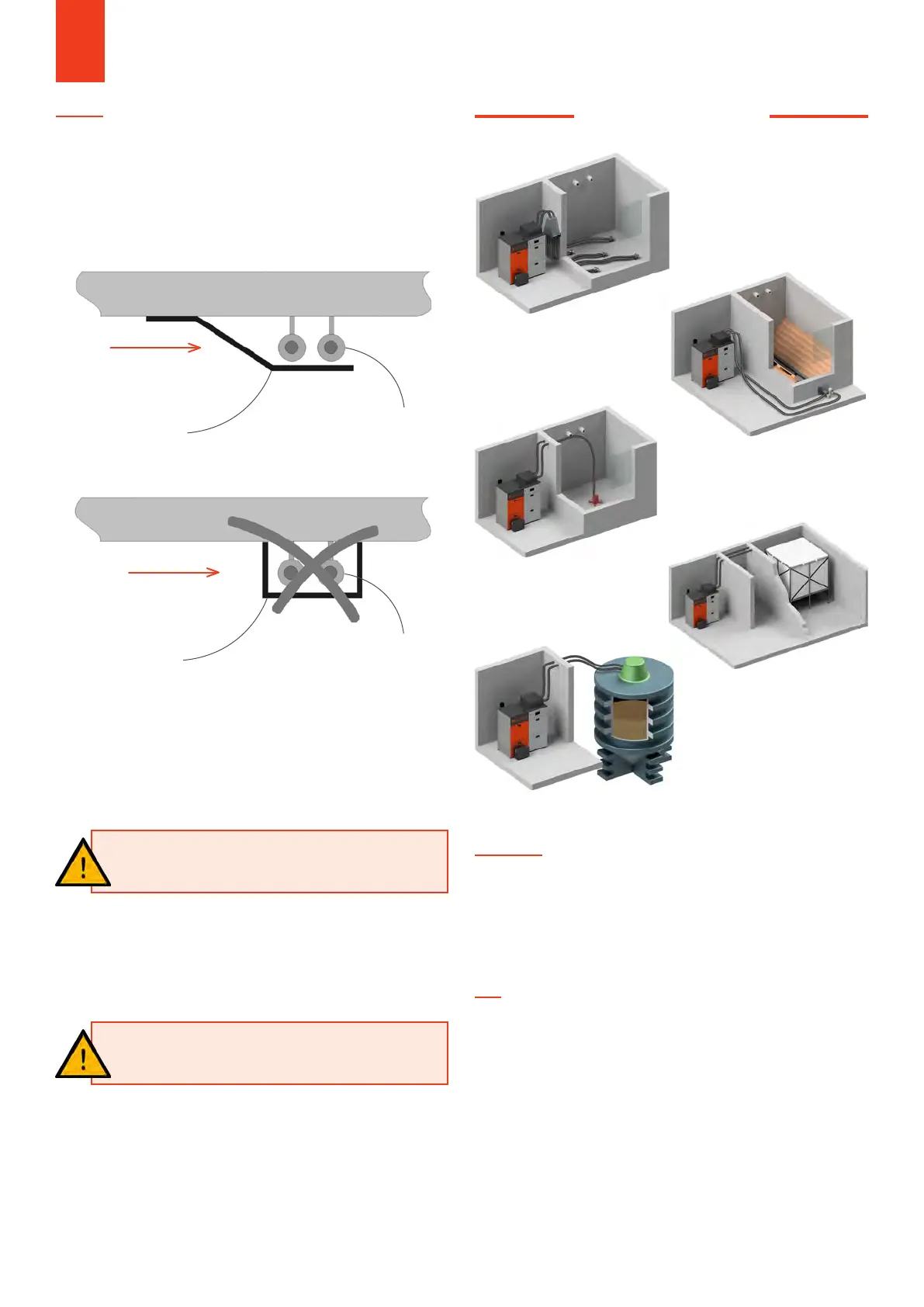

Other discharge systems can also be used upon request or

after consultation and approval by Biotech Energietechnik

GmbH. The use of non-approved discharge systems

invalidates the guarantee / warranty.

The PZ 100 RL has two independent discharge systems from the

storage room to the intermediate container. Due to the design,

the warehouse is emptied unevenly via the two discharge

systems. When one storage area becomes empty, the aected

discharge system is automatically deactivated. The second

discharge system continues to operate. After filling the store, as

soon as both delivery systems can be supplied with fuel again,

this must be acknowledged on the system via the control panel.

Both delivery systems are then active again.

FIRE PROTECTION

according to country-specific regulations.

ATTENTION:

Exeption for explosion-proof versions.

6.8 FIXTURES IN THE PELLET STORE

7.1 ADJUSTATION VARIATIONS

7.2 EXTRACTION SYSTEMS PZ 90/100 RL

Trajectory of the pellets

to be protected

lines, pipes etc.

Deflector plate

Deflector plate

to be protected

lines, pipes etc.

Trajectory of the pellets

7. DELIVERY SYSTEMS

SUCTION SYSTEM*

SCREW DISCHARGE

MOLE DISCHARGE

BAG SILO

UNDERGROUND TANK

Loading...

Loading...