23

WITHOUT LIGHT SHAFT WITH LIGHT SHAFT

Closing lid

Coupling spigot

NW 100 (Storz Type A)

Mount filling couplings firmly

in the storage room wall

Closing lid

Earthing

clamp

FILLING SYSTEM

Two „filling nozzles“ are required to fill a

pellet store. An extraction fan is connected

to one filling nozzle when the fuel is

delivered and the pellets are blown in at the

other. A wall opening with a diameter of 125-

150 mm must be made on site. The filling

couplings are firmly installed in this opening

with suitable material (they must not loosen

when filling the store). The permissibility of

installation foam must be clarified in advance

with the pellet supplier.

PLANING FOLDER PELLET BOILER

GENERAL NOTES

• Only metal pipes or earthed plastic pipes may be used for

the filling system.

• The filling system must be earthed against electrostatic

charges.

• The filling pipes or filling lines used must be smooth-

walled throughout on the inside, any necessary

extensions of the pipes via sleeves.

• When welding pipes, there must be no burrs or weld

seams protruding on the inside.

• The filling system must not end with a bend, but a

straight pipe section of at least 500 mm must follow after

a bend as a calming section.

NOT TO BE USED:

• Pipes made of plastic (danger of electrostatic charges).

• Pipes that can destroy the pellets during the filling process

due to their nature (e.g. spiral ducts from ventilation

technology).

ATTENTION!

The filling couplings must be firmly connected to the masonry. Earthing via the equipotential bonding is neces-

sary to prevent electrostatic charges during the filling process! The impact protection mat must be mounted in

such a way that the injection nozzle is opposite! Minimum distance between the filling couplings: min. 0.5 m!

6.6 NOTES ON THE EXECUTION

OF THE FILLING SYSTEM

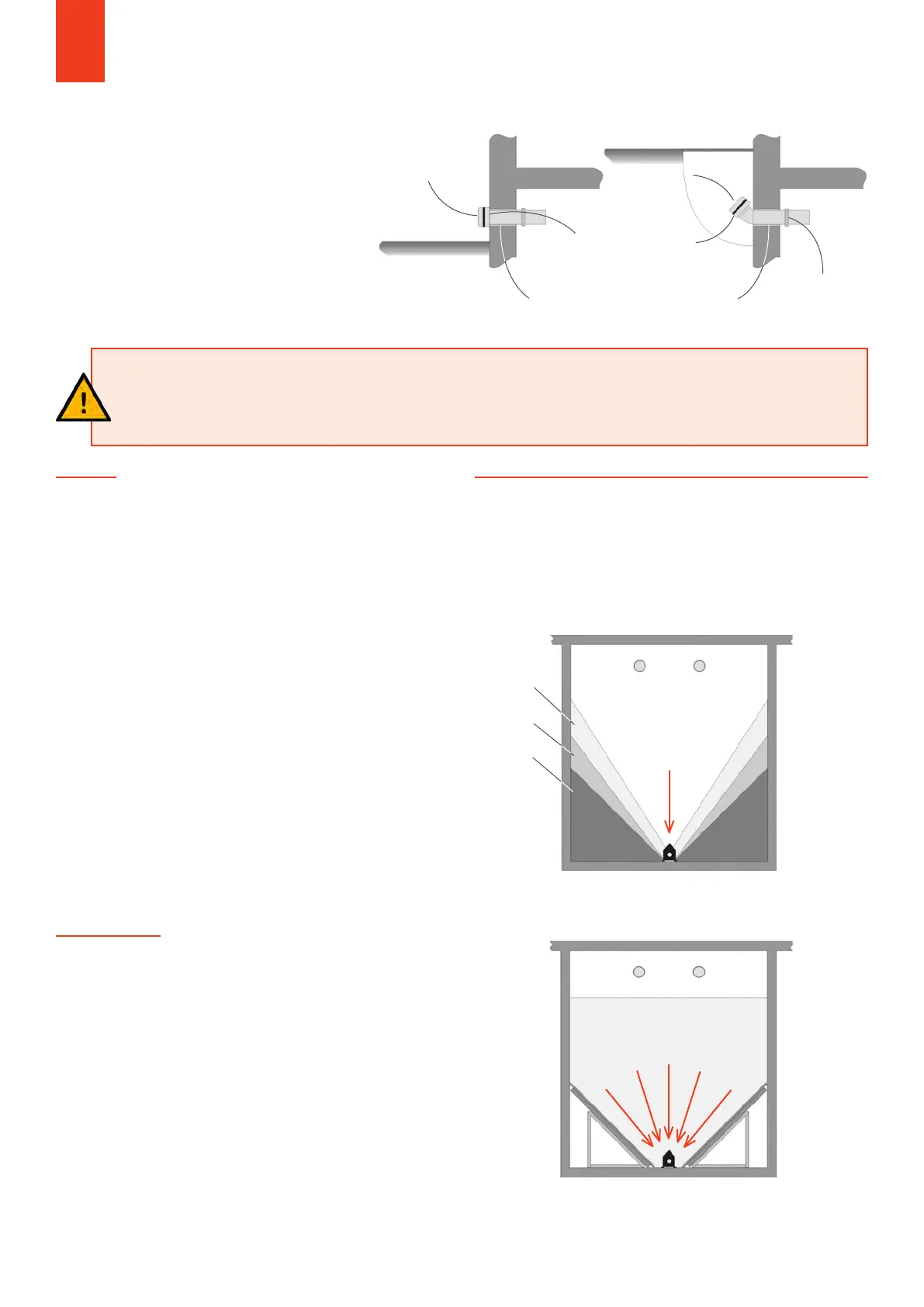

6.7 SLOPING FLOOR

The storage room must be designed with sloping floors so

that it can be almost completely emptied via the extraction

system used (e.g. screw discharge, probe discharge).

GENERAL NOTES:

• The angle of the sloping floor must be 45° so that the

pellets slide down automatically.

• The slanted floor should preferably be made of derived

timber products with a surface that is as smooth as

possible (e.g. chipboard or coated chipboard. OSB

boards tend to have a rough surface).

• The sloping floor must be able to withstand the static

requirements of the weight load from the pellets (density

650 kg/m³).

• Suitable angle beams are available for the substructure,

which facilitate the assembly of the sloping floor.

• The sloping floor should be made tight enough to the

connection to the storage room walls so that no pellets

can trickle into the empty space (these cannot be

removed from there).

• The sloping floor must not reduce the lateral openings

between the conveyor channel and the cover during

screw discharge.

WITHOUT SLOPING BOTTOM

- Increasing slope angle

WITH SLOPING BOTTOM 45°

- Almost complete emptying

depending on pellet quality

- Constant slope angle

1. Filling

2. Filling

3. Filling

Loading...

Loading...