28

7.5.2 ASSEMBLY

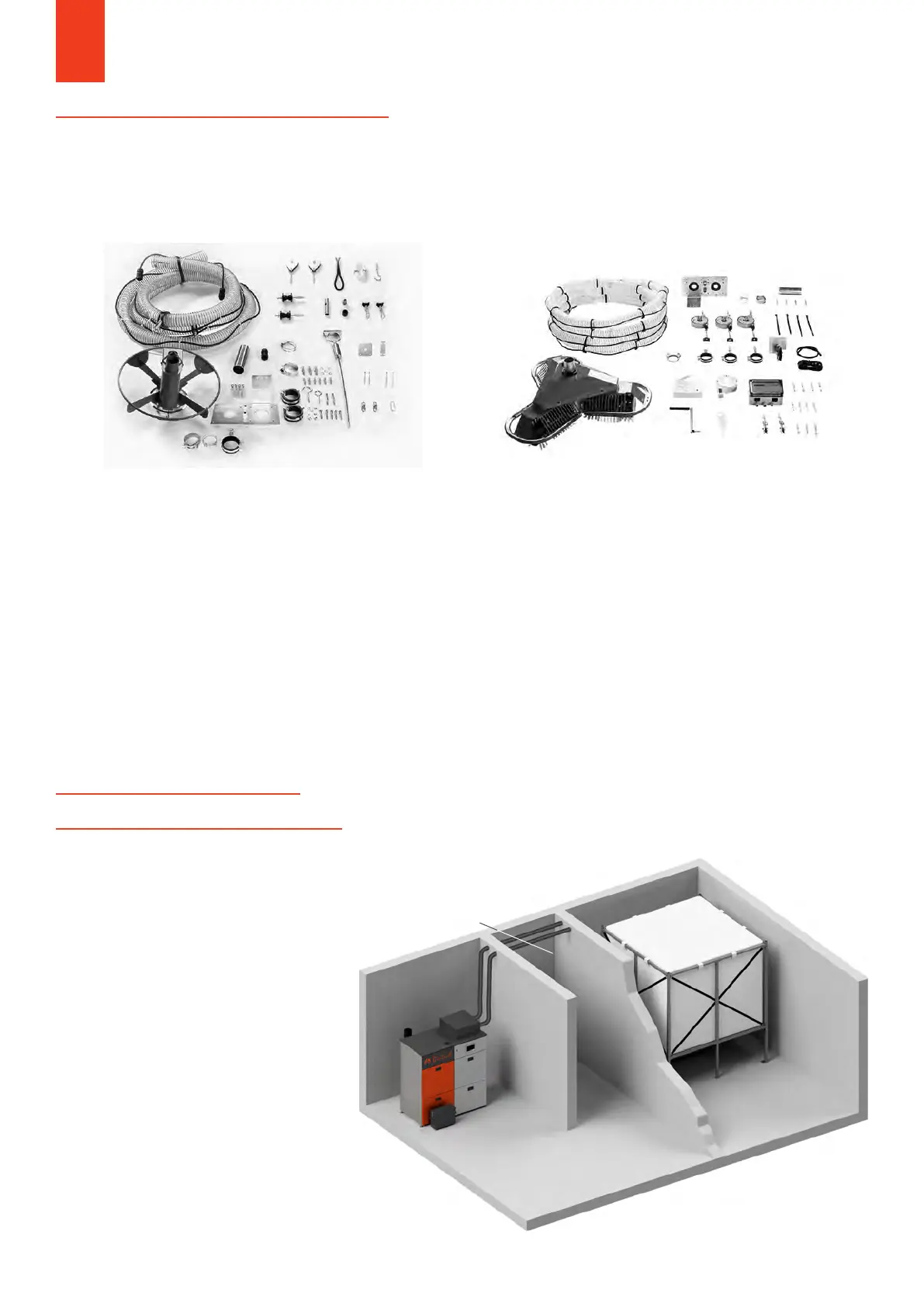

PELLET MOLE

The Sonnen-Pellet Mole ® Classic is the removal system for

all common storage options. Removal from the top ensures

reliable and gentle transport of the wood pellets into the boiler.

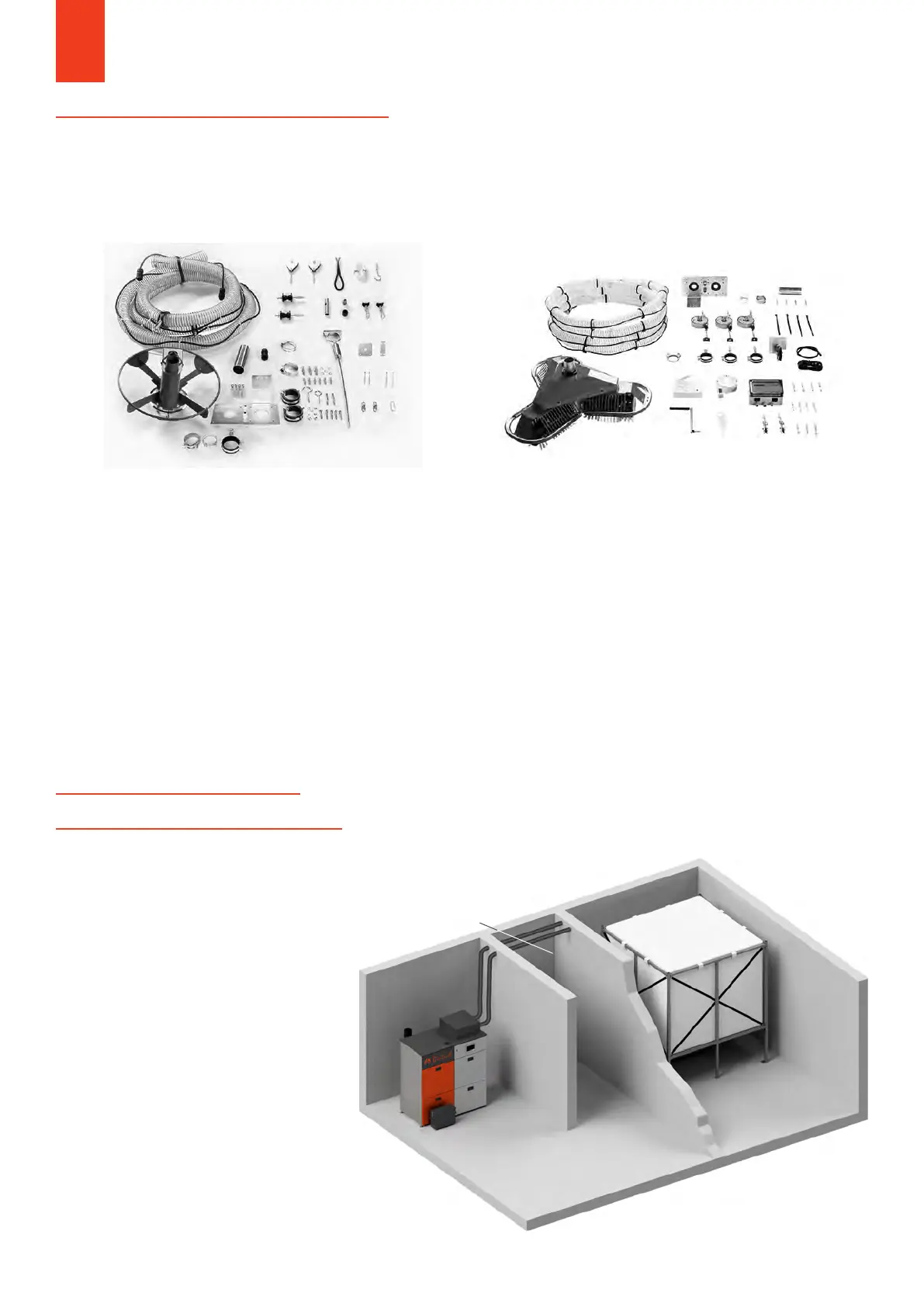

PELLET MOLE E3

The Pellet Mole E3 can be placed in storage rooms of almost

any shape thanks to the sensor technology. It can cover up

to 40m² and saves time and costs. The installation of this

discharge method is done in a few simple steps and is ready

for operation.

SCOPE OF DELIVERY:

• Pellet Mole E3 Basic Unit

- Housing with centric suction pipe for hose DN 50 mm

- Three drive rollers, with wear-resistant round brushes

- Ready-to-connect, wired control with integrated

sensors

• Connection box with switching power supply

- Input for pellet demand by boiler

- Output for device supply

• Special wire spiral hose, 8 m ready for installation incl. 9

m electric cable and dust-tight cable plug connection, as

well as three spring balancers for suspension

• Wall duct for suction and return air hose DN 50mm incl.

small parts and mounting material

• Fastening material and small parts for hose assembly

SCOPE OF DELIVERY:

• Solar Pellet Mole Classic Basic unit with electric drive for

integration into the control system of a pellet boiler with

suction system

• Manual hoist (manual lifting device) incl. pull rope, rope

deflection and handle

• Suction hose (5 m) ready for installation incl. electric

cable and dust-tight cable plug connection

• Wall duct with 2 connections for suction and return air hose

• Small parts and assembly accessories

PLANING FOLDER PELLET BOILER

The pellets are sucked into the storage

container via a point suction system, which

is located in the flange-mounted removal

box under the bag silo. When using a bag

silo with a screw mounted in the extraction

box, the pellets are metered into the suction

hose via the screw. The bag silo is filled with

pellets via the filling spouts attached to the

steel frame. Dierent silo sizes are available

depending on the room size.

It should be noted that the PZ 90/100 RL

can consume over 400 kg of pellets per

day in full-load operation. Bag silos with a

correspondingly low filling volume, e.g. only

5 tonnes, must therefore be filled frequently

or several times per heating season and are

therefore unsuitable. Furthermore, some

silo manufacturers prescribe cleaning,

for example after every third emptying

of the silo. This would also be necessary

several times a year and therefore not

recommended.

7.6 DISCHARGE FROM THE BAG SILO

7.6.1 OPERATING PRINCIPLE

Bag silo

Storage room

Heating room

Chimney (e.g. Ø130 mm)

Inlet nozzle

Storz „A“

Loading...

Loading...