6

PLANING FOLDER PELLET BOILER

• Safety and monitoring devices must not be removed,

bypassed or otherwise rendered inoperative. Use a dust

mask during cleaning and ash disposal to avoid health

hazards and damage.

• Electrical connection: 230 V, 50 Hz; fuse protection 16 A,

tripping behaviour slow. Protective measure Zeroing with

Fi circuit breaker ( voltage limits according to EN-50160)

ATTENTION: ISO standard 60364 must be observed!

Operating limits: Max. Ambient temperature 0-45°C;

max. humidity 0-95 %.

• There must be an emergency heating switch (all poles

and all sides can be switched o) in front of the boiler

room! Switch it o before carrying out maintenance and

/ or service work!

• The heating system may only be installed and operated

in properly designed heating or installation rooms and

is not designed for outdoor use, nor may it be operated

if it is exposed to external influences of water (dripping,

splashing and jetting water).

• The combustion air in the heating or installation

room must be free of halogenated hydrocarbons (e.g.

contained in spray cans, solvents and cleaning agents,

paints, adhesives). The installation of a washing machine

and/or tumble dryer is also not permitted, otherwise the

guarantee / warranty will expire.

• A suitable vent valve must be fitted at the top of the boiler.

• The boiler must be filled with heating water according to

VDI 2035 or Ö-Norm H 5195-1.

• When connecting the pellets boiler to the water supply

or to the heating circuit, the pellets boiler must be

secured against excessive water pressure by means of

an appropriate safety device on the system side (e.g.

overpressure valve). According to the country-specific

regulations, a water shortage protection must be provided.

• When connecting the pellet boiler to the water supply,

an appropriate safety device on the system side must

ensure that non-potable water is prevented from being

sucked back into the water supply system.

• The fire protection regulations must be implemented on

site in accordance with the applicable ocial regulations!

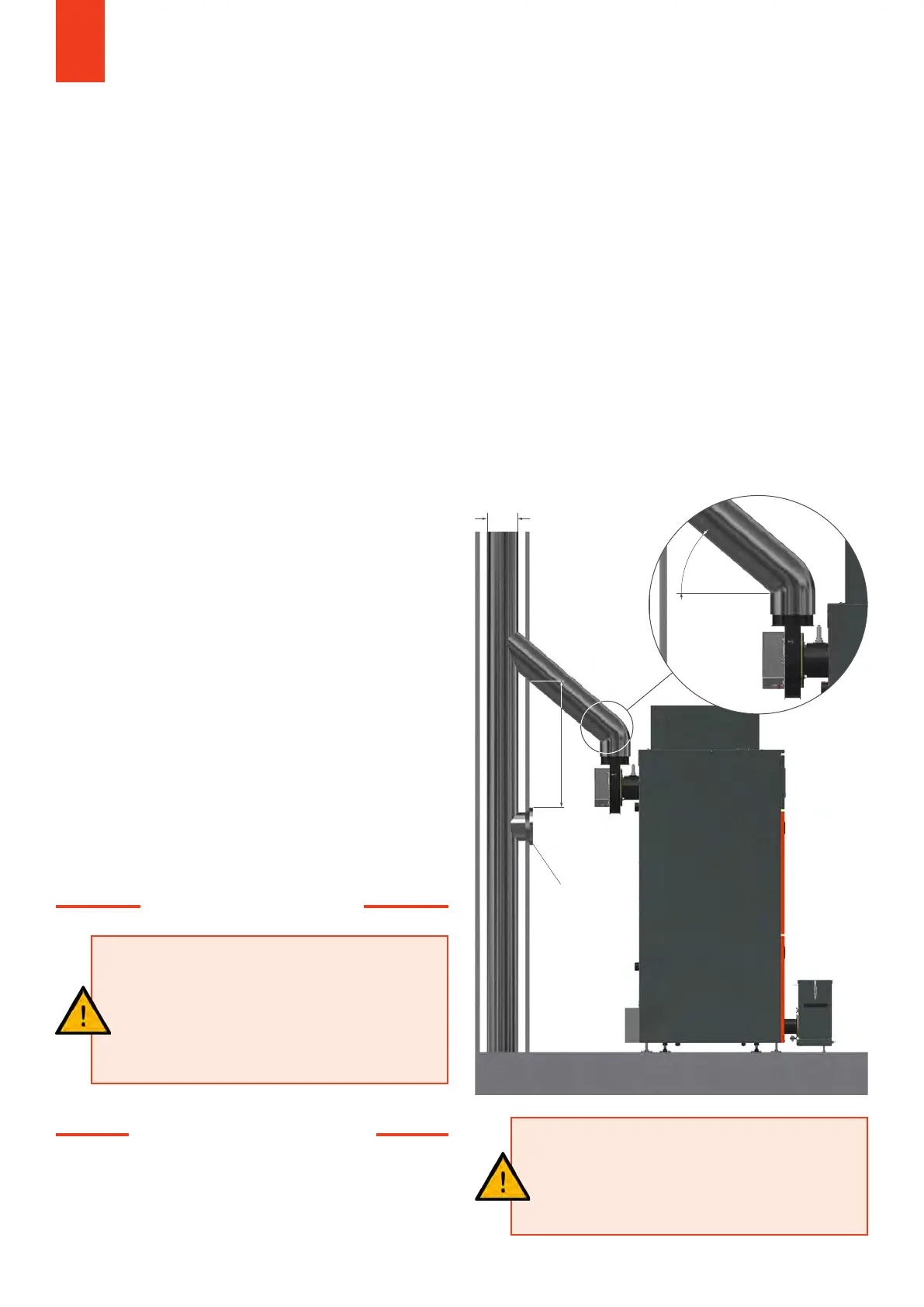

A moisture-resistant (FU) chimney (material 1.4401 or 1.4404

recommended) with a maximum flue draught of 10 Pa (0.10

mbar) is required. The connecting pipe (flue gas pipe) must

be laid with a minimum gradient of 10° (30-45° is optimal)

with a maximum length of 3.0 metres. The flue pipe must

be insulated with at least 25 mm. If possible, make the flue

connection with 45° bends. A connection with 90° bends can

cause flue gas problems. The flue pipe must be connected

to the chimney in such a way that no condensation water

can flow into the boiler. The boiler and the chimney must be

matched to each other (see chimney recommendation). EN

13384-1 must be used as a calculation aid.

REQUIREMENTS FOR THE FLUE PIPE

• Connect the flue pipe to the chimney at an angle of at

least 10°, ideally 30 to 45°.

• The exhaust pipe must not be reduced, the diameter of

the exhaust pipe must correspond to that of the exhaust

connection.

• The flue pipe must be pressure-tight and fitted with thermal

insulation at least 25 mm thick over its entire length.

• The draught regulator must be installed at least 600 mm

below the flue pipe inlet in the flue system.

ATTENTON!

The chimney must be insensitive to moisture

(FU)! The installation of a draught regulator is

required. A chimney calculation according to

standard EN 13384-1 is required (See page 7 & 8)!

2. RETURN FLOW BOOST

3. CHIMNEY SPECIFICATION

ACHTUNG!

It must be ensured that the return

temperature does not fall below 55°C under

any circumstances. Since this cannot be

guaranteed without an automatic return flow

increase, it is mandatory to install one! Failure

to comply will invalidate the warranty.

Ø 130-140 mm

Chimney

regulator

600 mm

≥ 10° (30-45°)

All dimensions in mm!

Loading...

Loading...