26

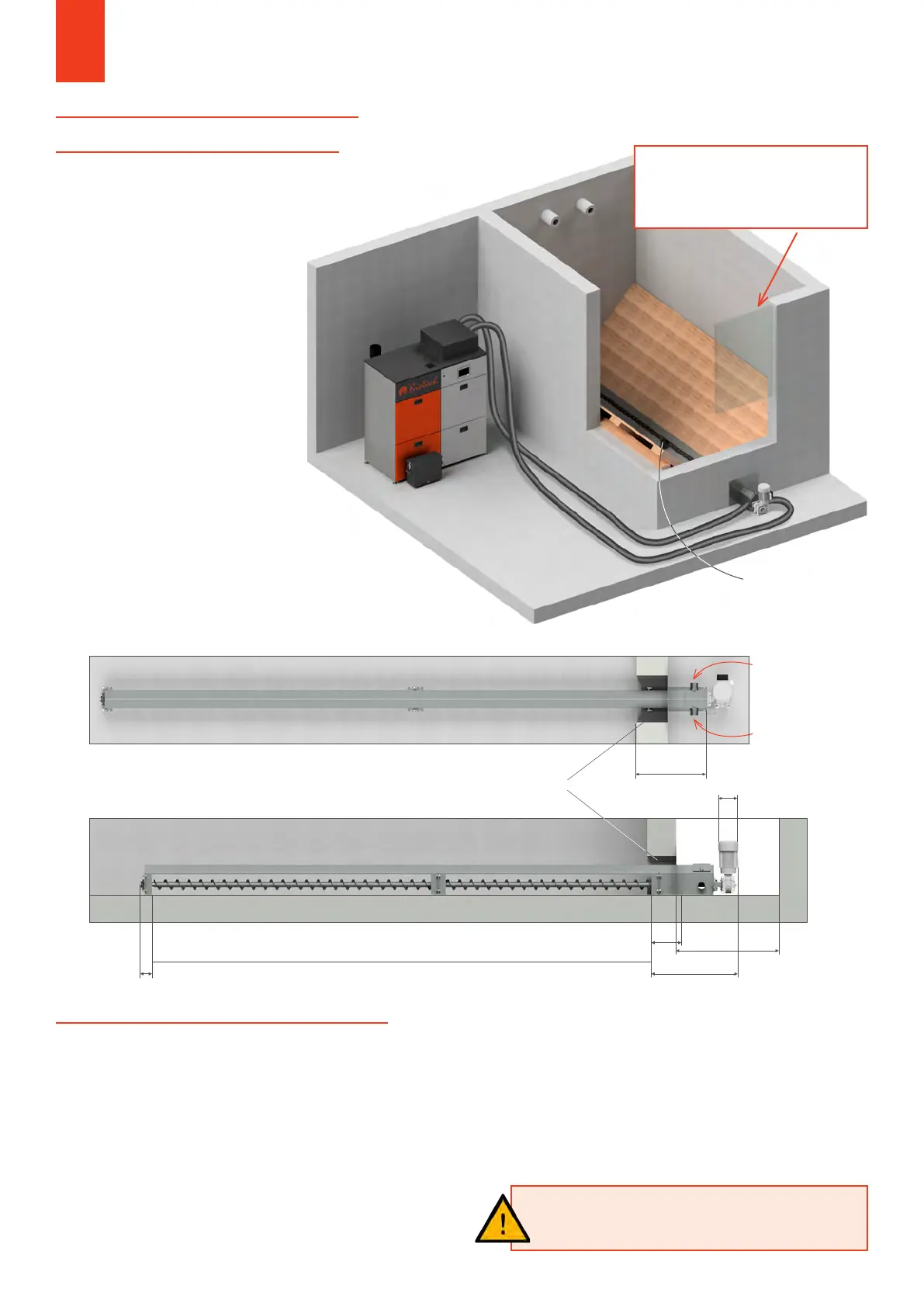

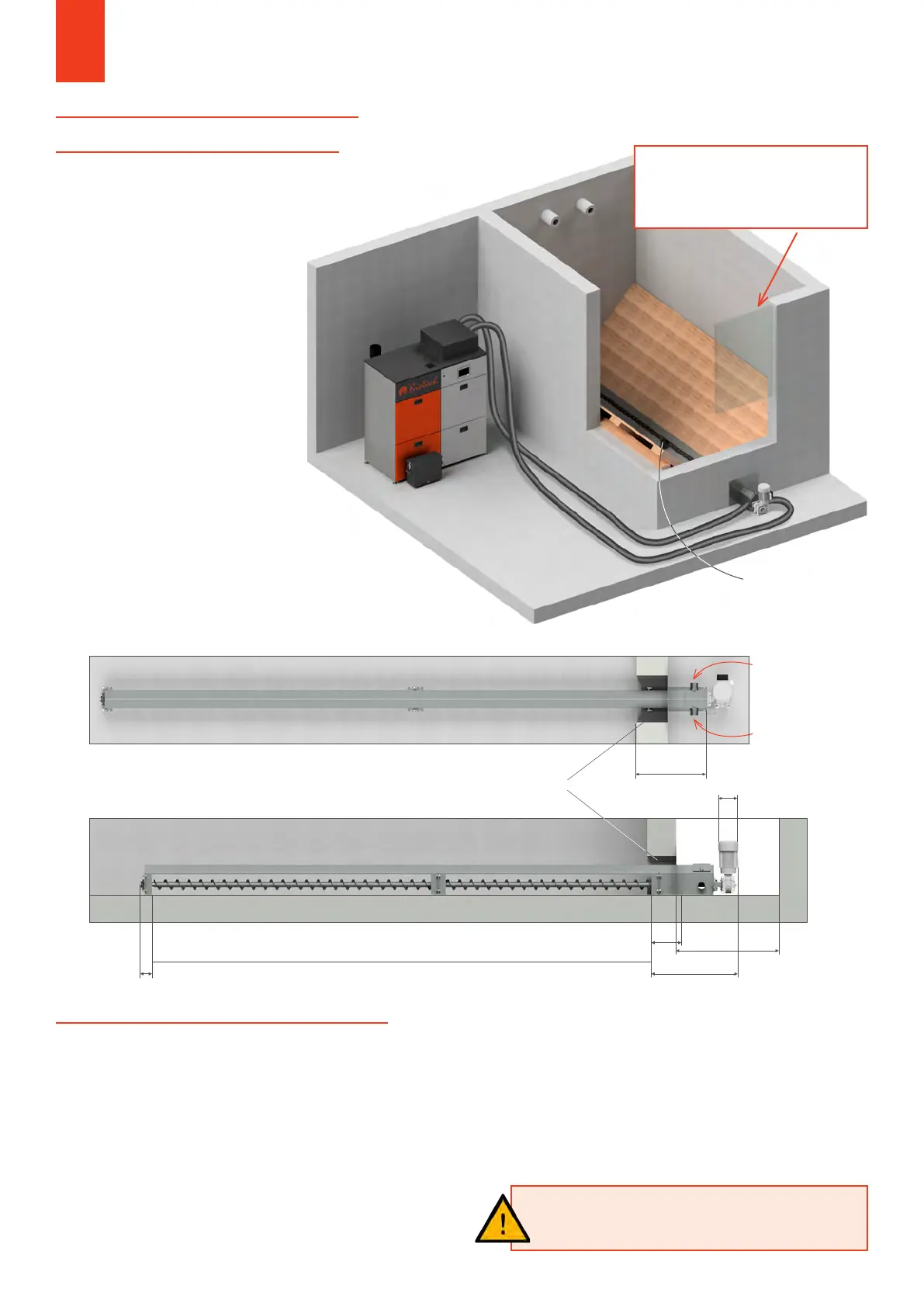

open channel (z.B. 2000 mm)

Wall recess 220 x 220 mm

All dimensions in mm!

Heating room

300

160

500

500

200

ca. 60

Storage room

Chimney (e.g.

Ø130 mm)

ATTENTION!

Distance impact mat wall min.

300 mm

The pellets are conveyed by the

auger from the storage room to

the suction point and sucked o

from there. The suction hose and

the return air hose are attached

to the screw head on the left and

right with the clamps supplied.

There are 5 dierent screw lengths

(1500 / 2000 / 2500 / 3000 / 3500

mm) available as standard. Divisible

versions are also available on request.

7.4 SCREW DISCHARGE

7.4.1 OPERATING PRINCIPLE

PLANING FOLDER PELLET BOILER

Screw 2000 mm

(open channel)

7.4.2 ASSEMBLY

Create a wall duct of at least 220 x 220 mm at the bottom

centre of the storage room wall. Push the screw discharge

through the wall lead-through into the storage room. The

open channel must always be completely in the storage

room.

The connections for the hoses and the motor must

be freely accessible on the outside of the storage room

and splash-proof.

Secure the auger to the floor with the dowels and screws

provided.

Sloping floors must be created in the storage room to the left

and right of the auger. The sloping floors should have a slope

of at least 45° to ensure that the pellets can slide down safely.

Fix the angle profiles (accessories) to the floor at a distance of

0.5 to 1.0 m (depending on the load-bearing capacity of the

superstructure) and mount the panels for the slopes on them.

ATTENTION:

The hose radius must be at least 25 cm!

Connection

suction hose

Return air hose

connection

Loading...

Loading...