Basic Measurements

30

T2AL 250V

SENSE

Ω4W

VΩ

LO

HI

!

10A

CATⅡ(300V)

CATⅠ(1000V)

350V

MAX

1000V

MAX

12A

MAX

mA

12A

INPUT

Resistance

Under Test

▲

▲

▲

▲

DC V AC V 2W Fr eq

Aut o

Tr i g

MX+B

Shi f t

Cont Rel

¦¸

Period

dB/m

FastMenu Recall Med Slow Hold

CHOICES

LEVEL

ENTER

ESC

LOCAL

%

IDC IAC 4W

Ω

FAST

MED

SLOW

ADRS RMT HOLD TRIG

*

MEM AUTO REL FILT MATH SHIFT

4W

ERR

POWER

R

5

5492B

1

2

/

Dig it Multimet er

Note: Source current flows from the INPUT HI to INPUT LO terminals.

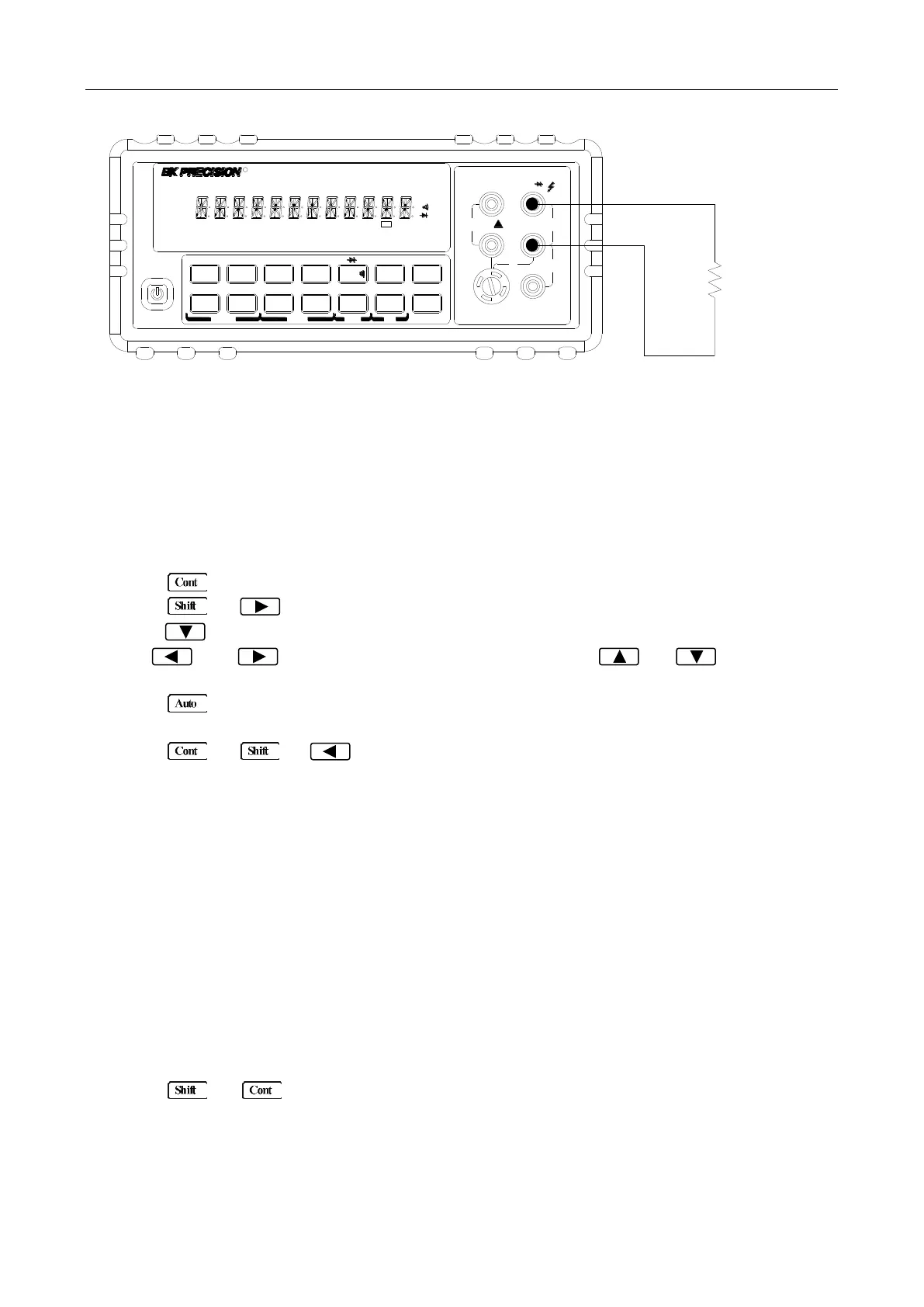

Figure 3-5 Continuity Measurement

3.6.2 Threshold resistance level

You can define a threshold resistance from 1 Ω to 1000 Ω. Factory default value is 10 Ω. Follow the steps

below to define the resistance level:

1. Press for Continuity Measurement.

2. Press → to enter the submenu level, “1: CONTINUITY” will be displayed.

3. Press to enter the parameter level, the current LEVEL value will be displayed.

4. Use and keys to change the cursor position and use and keys to

increment or decrement the digits respectively. Enter a value from 1 to 1000.

5. Press (ENTER) to confirm your setting. Message “CHANGE SAVED” will be displayed for a

moment.

6. Press or → to exit the menu and return to the continuity measurement.

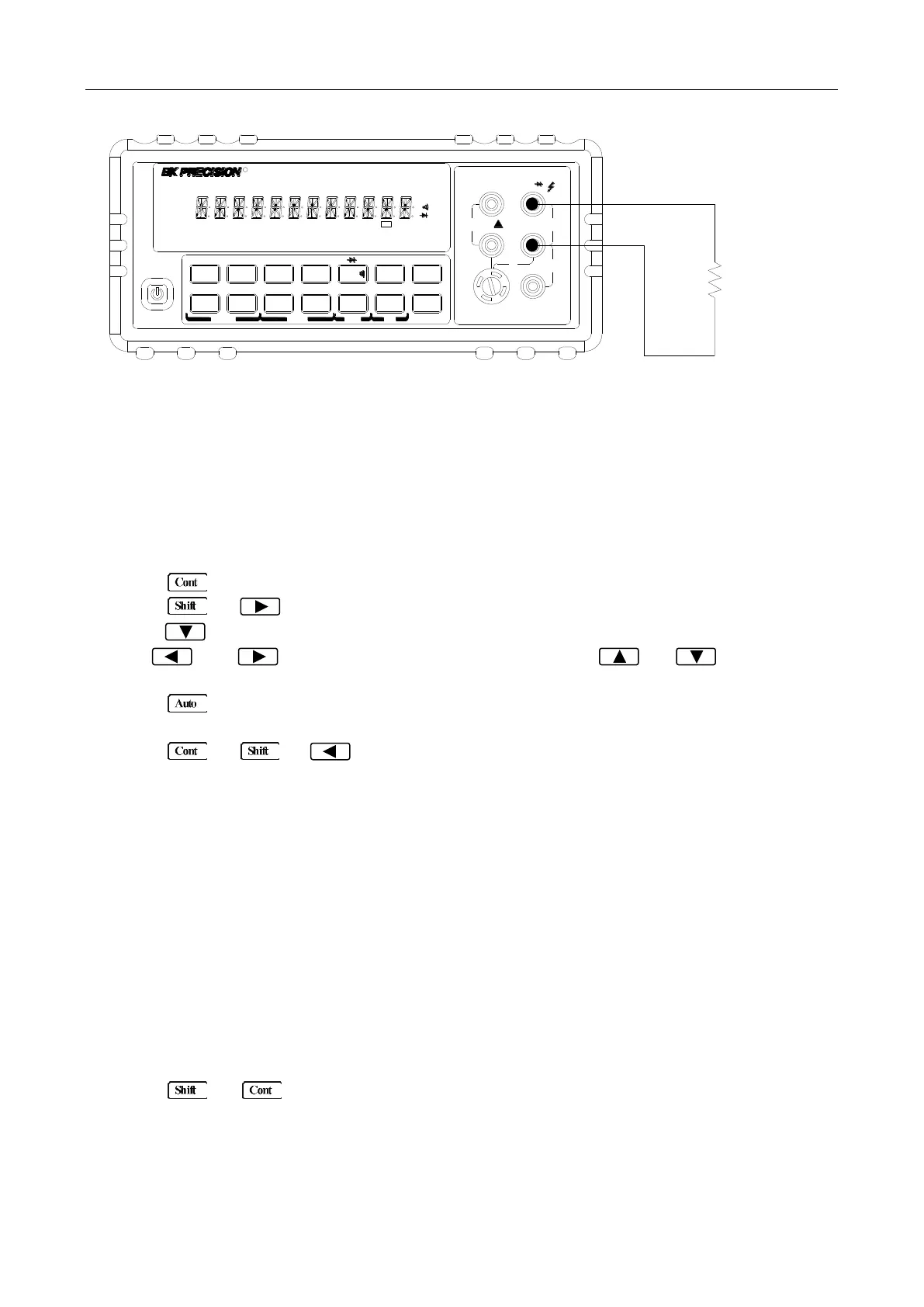

3.7 Testing Diode

The multimeter can also be used to measure the forward voltage drop of general-purpose diodes and

zener diodes. A current range (1 mA, 100 μA, or 10 μA) can be selected for diode measurement.

Note: Diode testing defaults to MED (1 PLC) rate and cannot be changed.

3.7.1 Connections

Assuming the multimeter is under factory default conditions, the basic procedure for diode testing is as

follows:

1. Connect test leads to INPUT HI and LO terminals.

2. Press → for diode measurement function.

3. Connect test leads to the diode under test as shown in Figure 3-6.

4. Take a reading from the display.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Loading...

Loading...